15

Defiant Woodburning Stove

30003841

To close the doors, always close the left door first. Turn

the handle in the right door to the left and up (to the

open position) and close it. Finally, push on the door as

you turn the handle to the right and down. The doors

will draw in slightly, and the handle should offer some

resistance as you turn it to the closed position.

To reduce the risk of breaking the glass, avoid striking

the glass or slamming the doors.

When you’re not using the door handle, store it in the

holder behind the left front leg of the stove. Be careful

to not drop the handle, since it is breakable.

This stove is designed to operate efficiently with

the fire doors (front doors and griddle) closed. The

firebox and ash doors should be kept closed at all

times except when refuelling or removing ashes.

Infra-Red Reflective Glass Panels

for Clear Fire Viewing

The outer surfaces of the ceramic glass panels have

an infrared-reflective coating which keeps the inner

surfaces warm. This design, along with a pre-heated

‘airwash,’ makes clear fire viewing possible at most fir-

ing levels.

Andirons Help Protect the Glass

Your stove has andirons to keep logs away from the

glass panels. The andirons are essential to maintain

clear fireviewing, and should be left permanently in

place. Since the andirons may slightly hinder refueling

through the front doors, most stove owners will prefer

the convenience of top loading through the griddle. Do

not place fuel between the andirons and the doors.

Burn Only High-Quality Wood

The Defiant is designed to burn natural wood only; do

not burn fuels other than that for which it was designed.

You’ll enjoy the best results when burning wood that

has been adequately air-dried. The wood should be

559-610 mm (22-24”) in length. Avoid burning “green”

wood that has not been properly seasoned.

Do not

burn construction materials;

they often contain

chemicals and metals that can damage the catalytic

combustor or pollute the air. Do not burn ocean drift-

wood; when it burns, the salt it absorbs will attack the

cast iron.

The best hardwood fuels include oak, maple, beech,

ash, and hickory that has been split, stacked, and air-

dried outside under cover for at least one year.

If hardwood is not available, you can burn softwoods

that include tamarack, yellow pine, white pine, East-

ern red cedar, fir, and redwood. These should also be

properly dried.

Store wood under cover to keep it dry. The longer it is

stored, the better heating and fire-viewing performance

you will enjoy. Even for short-term storage, however,

keep wood a safe distance from the heater and keep

it out of the areas around the heater used for refueling

and ash removal.

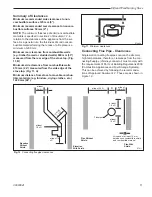

A Surface Thermometer is a Valuable

Guide to Operation

An optional surface thermometer tells you when to ad-

just the air control, and when to refuel. (Fig. 25)

ST523

Intrepid

temp readings

11/00

ST523

Fig. 25

Take temperature readings with a thermometer lo-

cated in the middle of the griddle.

For example, when the thermometer registers at least

230° C (450° F) after start-up you know that the stove

is hot enough to begin catalytic combustion and that it

may be time to close the damper. Note that the stove

will warm up much sooner than the chimney, though; a

warm chimney is the key to easy, effective stove opera-

tion. Please review the draft management information

on Page 24 to see how the size, type, and location of

your chimney will affect your stove operation. When

thermometer readings drop below 175° C (350° F) it’s

time to adjust the air control for a higher burn rate or to

reload the stove. A temperature reading over 385° C

(750° F) is a sign to cut back on the air supply to slow

the burn rate.

Use the following temperature ranges as a guide:

•

Readings in the 175°-260° C (350°-500° F) range

indicate low to medium heat output.

•

260°-315° C (500°-600° F) readings indicate me-

dium heat output.

•

Readings of 315-385° C (600°-750° F) indicate high

heat output. Operating your Defiant continuously at

griddle temperatures of 385° C (750° F) or higher

may damage the cast iron or enamel finish.

Use the Air Control Settings

that Work Best for You

No single air control setting will fit every situation. Each

installation will differ depending on the quality of the

fuel, the amount of heat desired, and how long you wish

the fire to burn; outdoor air temperature and pressure

also affect draft.

The control setting also depends on your particular

installation’s “draft,” or the force that moves air from the

stove up through the chimney. Draft is affected by such