20

Defiant Woodburning Stove

30003841

A stove is part of a system, which includes the chimney,

the operator, the fuel, and the home. The other parts of

the system will affect how well the stove works. When

there is a good match between all the parts, the system

works well.

Wood stove or insert operation depends on natural

(unforced) draft. Natural draft occurs when the smoke

is hotter (and therefore lighter) than the outdoor air at

the top of the chimney. The bigger the temperature

difference, the stronger the draft. As the smoke rises

from the chimney it provides suction or ‘draw’ that pulls

air into the stove for combustion. A slow, lazy fire with

the stove’s air inlets fully open indicates a weak draft.

A brisk fire, supported only by air entering the stove

through the normal inlets, indicates a good draft. The

stove’s air inlets are passive; they regulate how much

air can enter the stove, but they don’t move air into it.

Depending on the features of your installation - steel

or masonry chimney, inside or outside the house,

matched to the stove’s outlet or oversized - your

system may warm up quickly, or it may take a while to

warm up and operate well. With an ‘airtight’ stove, one

which restricts the amount of air getting into the firebox,

the chimney must keep the smoke warm all the way to

the outdoors in order for the stove to work well. Some

chimneys do this better than others. Here’s a list of

features and their effects.

Masonry Chimney

Masonry is a traditional material for chimneys, but it

can perform poorly when it serves an ‘airtight’ stove.

Masonry is a very effective ‘heat sink’ - it absorbs a lot

of heat. It can cool the smoke enough to diminish draft.

The bigger the chimney, the longer it takes to warm up.

It’s often very difficult to warm up an outdoor masonry

chimney, especially an oversized one, and keep it

warm enough to maintain an adequate draft.

Steel Chimney

Most factory-made steel chimneys have a layer of

insulation around the inner flue. This insulation keeps

the smoke warm. The insulation is less dense than ma-

sonry, so a steel chimney warms up more quickly than

a masonry chimney. Steel doesn’t have the good looks

of masonry, but it performs much better.

Indoor/Outdoor Location

Because the chimney must keep the smoke warm, it’s

best to locate it inside the house. This uses the house

as insulation for the flue and allows some heat release

into the home. An indoor chimney won’t lose its heat

to the outdoors, so it takes less heat from the stove to

heat it up and keep it warm.

Chimney Height

The common wisdom tells us that a taller flue draws

better than a short one. This isn’t necessarily so. If a

chimney is tall enough to meet the safety requirements

of the 2/3/10 foot rule, then adding more height isn’t the

right answer to a draft problem. In fact it could make the

problem worse, by adding more mass to the chimney

system, which the smoke must warm up, at the far end

from the heat source (the stove). Don’t make a chimney

taller unless you must to meet the safety rules, or un-

less there’s some nearby feature causing a downdraft.

Even then, there are downdraft-preventing chimney

caps available, which are probably the smarter choice.

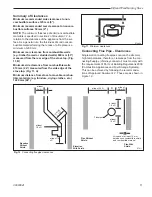

Flue Sizing

The inside size of a chimney for an ‘airtight’ stove

should match the size of the stove’s flue outlet. When

a chimney serves an airtight stove, more is not better;

in fact, it can be a disadvantage. Hot gases lose heat

through expansion; if we vent a stove with a six-inch

flue collar (28 square inch area) into a 10 x 10” flue,

the gases expand to over three times their original size.

This cools the gases, which weakens draft strength. If

an oversized flue is also outside the house, the heat it

absorbs gets transferred to the outdoor air and the flue

usually stays cool.

It’s common for a masonry flue, especially one serving

a fireplace, to be oversized for the stove. It can take

quite a while to warm up such a flue, and the results

can be disappointing. The best solution to an oversized

flue is an insulated steel chimney liner, the same diam-

eter as the stove or insert’s flue outlet; the liner keeps

the smoke warm, and the result is a stronger draft. An

uninsulated liner is a second choice - the liner keeps

the smoke restricted to its original size, but the smoke

still must warm up the air around the liner. This makes

the warm-up process take longer.

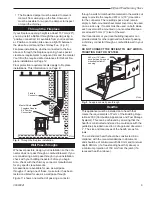

Pipe & Chimney Layout

Every turn the smoke must take as it travels to the

chimney top will slow it down. The ideal pipe and chim-

ney layout is straight up from the stove, to a completely

straight chimney. If you’re starting from scratch, use this

layout if possible. If the stovepipe must elbow to enter a

chimney, locate the thimble about midway between the

stove top and the ceiling. This achieves several goals:

it lets the smoke speed up before it must turn, it leaves

some pipe in the room for heat transfer, and it gives you

long-term flexibility for installing a different stove without

relocating the thimble.

Draft Management