Table of Contents

i

Regulatory Agency Console Documentation ....................................................................1

Related Manuals ...............................................................................................................1

Safety Symbols .................................................................................................................2

Control Drawing ................................................................................................................3

National Electrical Code Compliance ................................................................................4

Mounting the Console .......................................................................................................7

Wiring the Console ...........................................................................................................9

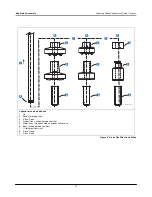

Probe Manhole Installation .............................................................................................13

Probe Installation ............................................................................................................13

Probe Conduit Installation ...............................................................................................14

Wiring Run Methods .......................................................................................................15

Connecting Probes to the Console .................................................................................18

Probe Wiring Precautions ...............................................................................................19

Surge Protection for Communication Devices ................................................................23

Restricting System Programming Access .......................................................................24