VAN'S AIRCRAFT, INC.

PAGE:

REVISION:

DATE:

01/19/19

0

RV-12iS

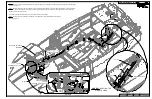

42PiS-02

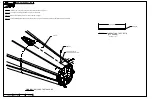

NOTE: If the VS-1213 V-Stab Tip Fairing has already been riveted to the top of the V-Stab Assembly, it be will necessary to

drill out the rivets securing the fairing.

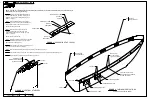

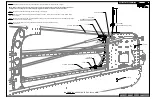

Step 1: Separate the F-00205 Nutplate Spacer

into the F-00205 Shim, K1000 Drill Temp, and

MS20151 Drill Temp by cutting along the lines

shown in Figure 1.

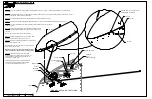

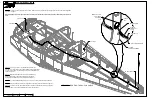

Step 2: Cleco the MS21051 Drill Temp to the

aft-most hole in the VS-1213. Match-drill #40 the

holes into the VS-1213 as shown in Figure 2.

Repeat for the opposite side.

Step 3: Cleco the K1000 Drill Temp to the

remaining #30 holes in the VS-1213, then

match-drill #40 the holes into the VS-1213 as

shown in Figure 2.

Repeat for the opposite side.

Step 4: Machine countersink (flush outside) all #40

holes just match-drilled into the VS-1213 for an

AN426AD3 rivet. See Figure 2.

Step 5: Final-drill #27, then machine-countersink all

#30 holes in the VS-1213. See Figure 2.

Step 6: Rivet the nutplates onto the inside of the VS-1213 as shown in Figure 2.

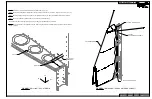

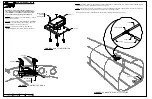

Step 7: Final-drill #27 all holes in the VS-1201 Main Skin which are above the VS-1205 Tip Rib. See Figure 3.

Step 8: Dimple all #27 holes for #6 screws as shown in Figure 3.

CUT

F-00205 SHIM

K1000 DRILL TEMP

MS21051 DRILL TEMP

(#30 HOLE

ON SIDE)

(#30 HOLE

CENTERED)

(#12 HOLE

CENTERED)

FIGURE 1: SEPARATING THE F-00205

FIGURE 2: FAIRING MODIFICATIONS

(FAIRING SHOWN UPSIDE DOWN)

K1000 DRILL TEMP

MS21051 DRILL TEMP

1/8 CLECO

1/8 CLECO

10X MATCH-DRILL #40

2X MATCH-DRILL #40

2X

10X

VS-1213

MACH CSK

ALL #40 HOLES

(FLUSH OUTSIDE)

FINAL DRILL #27 THEN

MACH CSK FOR #6 SCREW

(FLUSH OUTSIDE)

12X

VS-1201

VS-1205

FIGURE 3: VERTICAL STAB PREP

FINAL-DRILL #27

DIMPLE FOR #6 SCREW

(FLUSH OUTSIDE)

MS21051L06

2X AN426AD3-4

K1000-06

2X AN426AD3-4