27

once a day. If haze or debris is present on the optical surfaces an optics cleaning should be

performed. As a general rule, if the machine itself is dirty the optics are probably dirty as well.

Follow these instructions to clean the optics:

4.3.1 FIAL FOCUS LES

a.

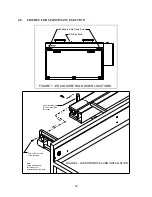

Remove the 4-40 thumb screw from the side of the lens holder located on movable

optics carriage. Hold on to lens holder while removing the screw so holder and lens

do not drop (reference Figure 3).

b.

Disassemble the lens holder assembly (lens holder housing, threaded insert, two lens

spacers, one lens reference Figure 4) by unscrewing the threaded insert keeping

housing flat so spacers and lens do not fall out.

c.

Stand over a table with hands resting on table top and remove lens from lens holder.

Hold lens holder in left hand and a clean sheet of lens tissue flat in right hand.

Carefully turn lens holder upside down onto tissue so that lens and spacers drop out

onto lens tissue.

d.

Inspect lens spacers and clean if necessary with a swab and lens cleaner.

e.

Hold lens by edges using lens tissue and thoroughly dust off the lens using a source of

oil free compressed air. A small hand held compressed Freon duster sold for use by

photographers is satisfactory. Take caution to hold can upright so propellant does not

escape with compressed air onto the optical element.. If lens is extremely dirty use a

stream of lens cleaning solution #1 from the small plastic wash bottle to flush both

surfaces instead.

f.

Apply lens cleaning solution #1 to one surface of the lens. Let sit for one minute

g.

Final cleaning is done by gently wiping, using several sheets of photographic lens

tissue soaked with lens cleaning solution #1.

h.

Dry optical surface with lens tissue.

OTE:

Never use the same tissue twice. Dust build-up on the tissue may scratch the

surface of the lens.

i.

Repeat steps f through h for second side of optical element.

j.

Inspect lens. If still dirty repeat cleaning procedure steps f through i until lens is

clean.