14

© 2021 United States Stove Company

OPERATION INSTRUCTIONS

BUILDING A FIRE

The top down method of fire building is recommended

for this appliance. Place the largest pieces of wood on

the bottom, laid in parallel and close together. Smaller

pieces are placed in a second layer, crossways to the

first. A third layer of still smaller pieces is laid crossways

to the second, this time with some spaces between.

Then a fourth layer of loose, small kindling and twisted

newspaper sheets tops off the pile.

WARNINGS:

• NEVER OVERFIRE YOUR STOVE. IF ANY PART

OF THE STOVE STARTS TO GLOW RED, OVER

FIRING IS HAPPENING.

• THE INSTALLATION OF A LOG CRADLE OR

GRATES IS NOT RECOMMENDED IN YOUR WOOD

STOVE. BUILD FIRE DIRECTLY ON FIREBRICK.

• NEVER PUT WOOD ABOVE THE FIREBRICK

LINING OF THE FIREBOX.

• ATTEMPTS TO ACHIEVE HEAT OUTPUT

RATES THAT EXCEED HEATER DESIGN

SPECIFICATIONS CAN RESULT IN PERMANENT

DAMAGE TO THE HEATER.

ADDING FUEL

1.

Once you have obtained a good bed of embers, you

should reload the stove.

2.

To do so, slowly open the door so it is open one

or two inches for 5 to 10 seconds, before opening

completely to increase the draft and thus eliminate

the smoke which is stagnant in a state of slow

combustion in the stove.

3.

Rake the embers to the front of the stove. Add about

7-7.5 lbs of fuel. This amount will prevent overload

or over

-

firing your stove. Close the door immediately.

4.

When adding fuel

,

be careful not to smother the fire.

Make sure the embers do not obstruct the air inlet

.

5.

Reloading of fuel should only occur once the prior

fuel load has burned down to embers. Abiding by

this routine, your stove will achieve the cleanest

emissions burn, plus will prevent

over-firing

of your

stove.

VISIBLE SMOKE

The amount of visible smoke being produced can be

an effective method of determining how efficiently the

combustion process is taking place in the given settings.

Visible smoke consists of unburned fuel and moisture

leaving your stove. Learn to adjust the air settings of your

specific unit to produce the smallest amount of visible

smoke. Wood that has not been seasoned properly and

has a high wood moisture content will produce excess

visible smoke and burn poorly.

AIR TUBES

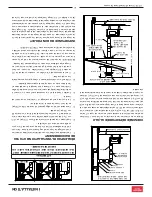

The air tubes assembled in this unit are designed to

provide an accurate mix of secondary air to ensure the

highest efficiency. Any damage or deterioration of these

tubes may reduce the efficiency of combustion.

SECONDARY AIR TUBES

The secondary air tubes must be cleaned with a wire

brush. If debris remains in holes lightly tap with a wooden

stick to remove.

SMOKE & CO MONITORS

Burning wood naturally produces smoke and carbon

monoxide(CO) emissions. CO is a poisonous gas when

exposed to elevated concentrations for extended

periods. While the modern combustion systems in

heaters drastically reduce the amount of CO emitted

out the chimney, exposure to the gases in closed or

confined areas can be dangerous. Make sure your stove

gaskets and chimney joints are in good working order

and sealing properly to ensure unintended exposure. It is

recommended that you use both smoke and CO monitors

in areas having the potential to generate CO.