14

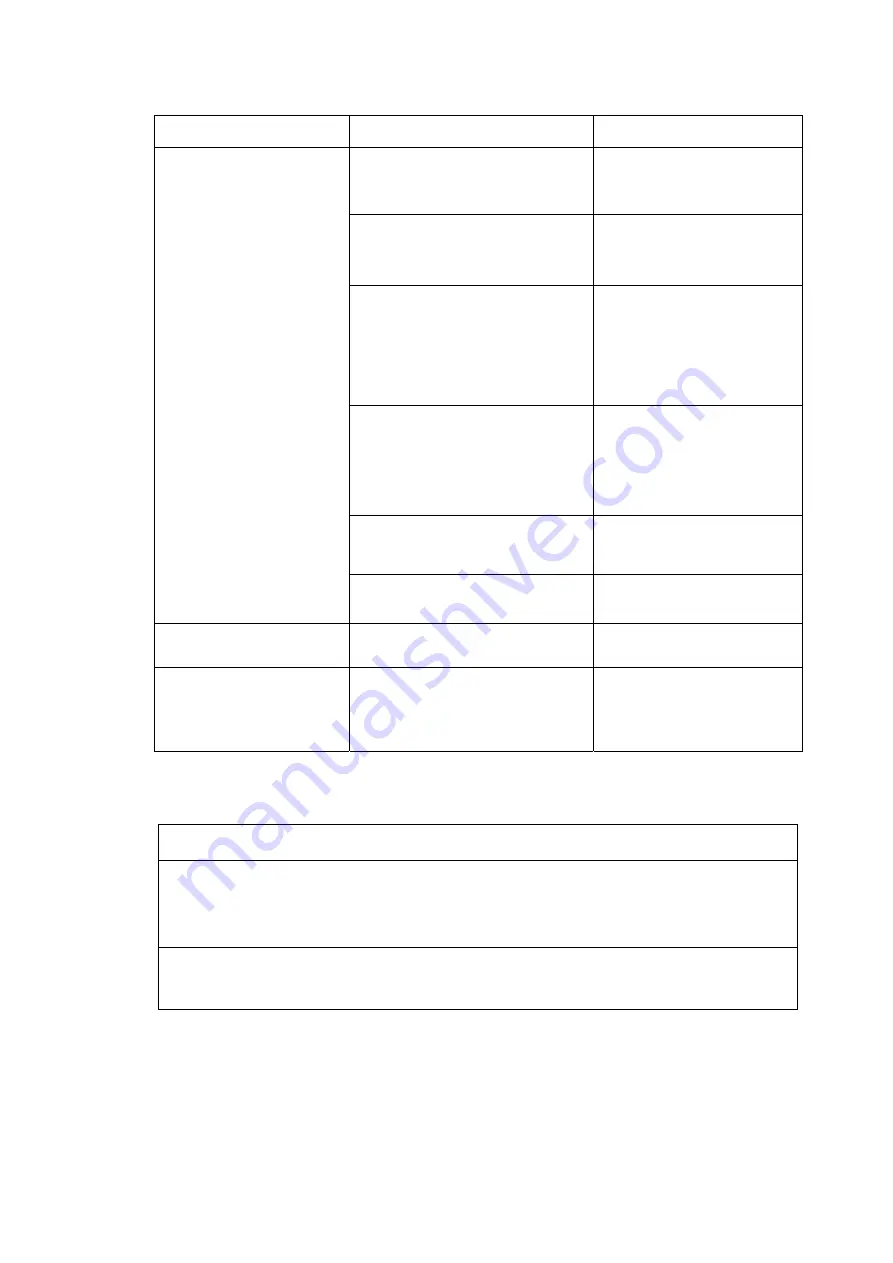

5. Troubleshooting

Symptom

Cause

Troubleshooting

Ultimate pressure is

low or unstable, or

evacuation

performance is low.

The ambient temperature at

the installation site is high.

Decrease the ambient

temperature to 25°C by

cooling.

Operation time is too long

after installation or long

termination.

Operate 24 hours to 48

hours, and then perform

checking.

Leakage is detected.

Check components that

were maintained before

ultimate pressure

changes.

Deterioration of the oil for

the oil diffusion pump.

If the cause of the

deterioration is clear

(incorrect air intake,

leakage, etc.), replace

the oil.

Failure in the oil sealed

vacuum pump

Refer to the Oil Sealed

Vacuum Pump User’s

Manual.

Failure in measuring

instrument

Replace the measuring

instrument.

The oil diffusion pump

stays cold.

The heater is disconnected. Replace the heater.

The thermal relay for

oil sealed vacuum

pump operates.

Overloaded

Refer to the Oil Sealed

Vacuum Pump User’s

Manual.

Thermal relay set

6. Storage of Equipment

Observe the following guidelines to store the equipment.

1) Place of storage

- Floor with sufficient strength - Location with good ventilation

- Location without direct sunlight - Location where no corrosive

chemicals or gases are present.

2) Cautions before and upon storing

- Perform roughing evacuation inside the chamber