Ultimaker PVA Removal Station user manual

20

5.2 Check the water saturation level

The water will slowly become saturated with PVA after each use. It is possible to use the water in the PVA

Removal Station for more than one print or cycle, but higher PVA saturation levels of the water negatively impact

the efficiency. Using fresh water will speed up the cleaning process. It is recommended to regularly check

the saturation level.

Tip:

Turn off the PVA Removal Station using the power button. The container illumination interferes

with the inspection.

1. Remove the top cover and lift the rinsing basket out of the container.

2. Look down into the PVA Removal Station at the saturation indicator at the bottom. This is located on top

of the magnetic rotor.

3. Determine if the ring can be divided into two colored segments.

4. If the ring appears as one uniform color, the water is saturated with PVA and the water should be disposed of.

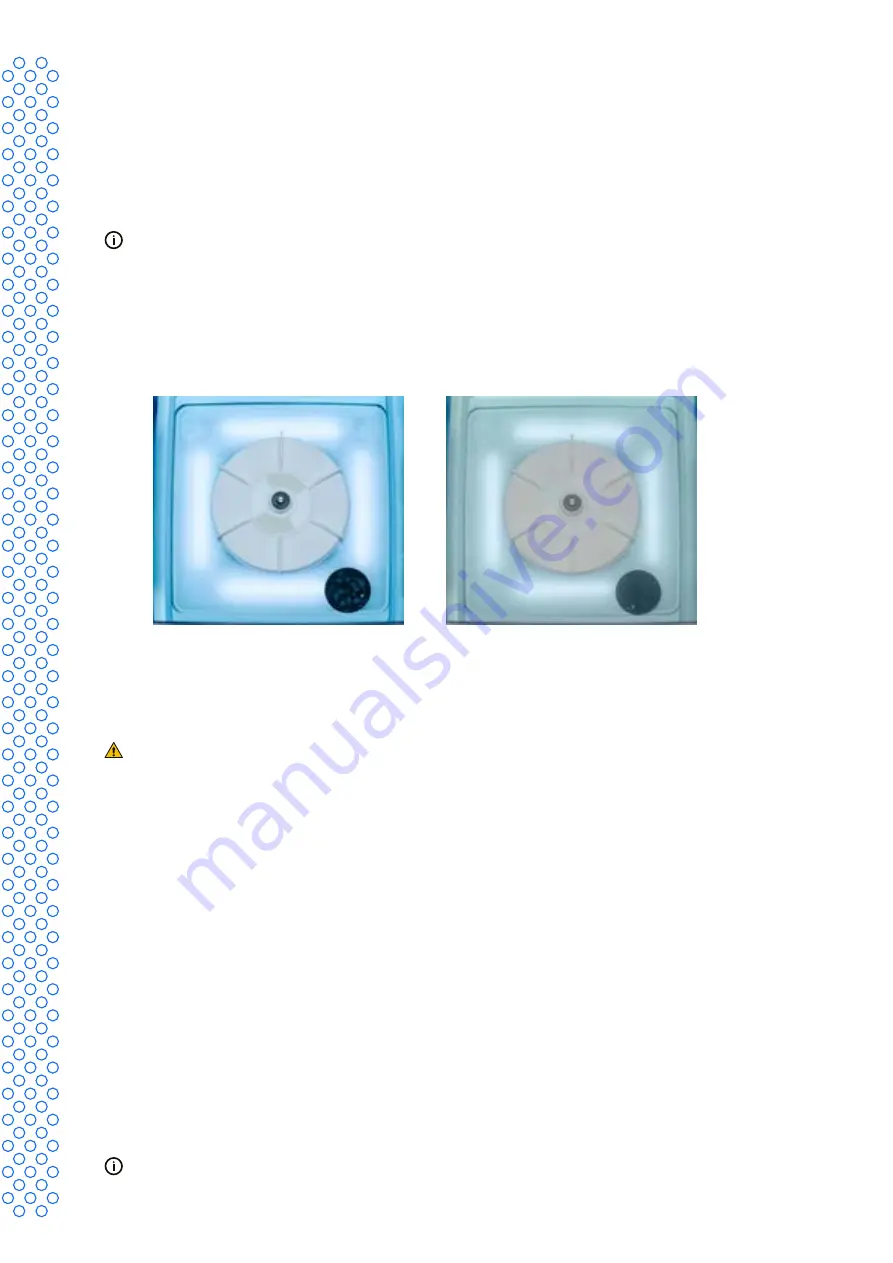

Fresh water

The ring on the rotor can still clearly be

divided into separate segments

Saturated water

The water looks yellowish and the segments

on the rotor ring are hard to distinguish

Highly saturated water will increase motor load and increase cleaning time. For optimum performance of the

Ultimaker PVA Removal Station, refresh the water immediately when the indication segments are not visible

anymore or when the water has not been refreshed for 1 month.

5.3 Disposal of wastewater

The container should be emptied in the following situations:

• When the water is too saturated with PVA (see

section 5.2

)

• When the water has not been refreshed in more than one month (see

section 5.1

)

• When the PVA Removal Station will not be used for a longer period of time (see

section 5.4

)

When emptying the container, it is highly recommended to stir the water first.

1. Turn on the PVA Removal Station using the power button.

2. Set the rotor speed to Normal.

3. Let the PVA Removal Station mix the water for 1 minute.

4. Remove the top cover and rinsing basket from the container and place them aside.

Tip:

The top cover turned upside down can be used as a dripping tray for the rinsing basket.

Summary of Contents for PVA Removal Station

Page 4: ...1 Safety and compliance...

Page 8: ...2 Introduction...

Page 11: ...3 Installation...

Page 14: ...4 Operation...

Page 19: ...5 Maintenance...

Page 23: ...6 Troubleshooting...

Page 26: ...7 Warranty...