General Guide to Router Cutters

32

Shanks and Cutter Length

1/2" shank cutters are inherently stronger which means

they are less likely to bend or snap than the small 1/4"

shank. Certain cutters can only be purchased on 1/2" shank

(door set and worktop cutters). This strength allows for

cutters of a larger diameter and longer length as appose to

the 1/4" shank.

It is very important with both 1/4” and 1/2” shanks to feed

the cut using a mixture of plunge depth and cutter shank.

This will reduce the damage to cutters and the wear on the

router bearings. Try to take more than one pass, this will

allow for a better finish and reduce damage to the router

and the cutters (1/4” is more likely to bend with a heavy

cut). As a general guide a 1/4” (6.35mm) cuter should take

less than half of this measurement as its cut i.e. 3mm.

This rule is very difficult to enforce as some cuts will

combine, using the total diameter and a side cut. So what

do we class as 3mm? The major factor being the material

density which will affect how much material can safely be

removed.

Modern cutters have to have a safe hold (K) line and a

maximum running speed engraved upon the shank as a

general guide. 2/3 of the cutter shank should be held in

the collet. As for speed, the noise of the router will give

you a guide.

The speed of the cutter will vary with materials but it is

important to vary the speed feed of the operator moving

the router over the work piece or the speed in which they

pass the work through the cutter set up on a table. Give

the cutter time to remove the stock to achieve a clean

finish.

1/4" Router Cutter

1/2" Router Cutter

Safe hold ‘K’ Line

Maximum speed of cutter

Diameter of cutter head

Height of cutter head

Diameter of shank

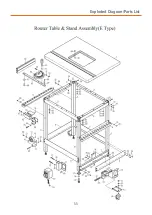

Summary of Contents for 717127

Page 7: ...What s Included 7 K L M N O P Q a b c d e g h i j N f...

Page 33: ...Exploded Diagram Parts List 33...

Page 38: ...Notes 38...

Page 39: ...Notes 39...