47

103536-08 - 4/18

iii.

Start burner and operate sufficiently to

boil the water without producing steam

pressure. Boil for about 5 hours. Open

boiler feed pipe sufficiently to permit a

steady trickle of water from the surface

blow-off pipe. Continue this slow boiling

and trickle of overflow for several hours

until the water coming from the overflow

is clear.

iv.

Stop burner and drain boiler in a

manner and to a location that hot water

can be discharged with safety.

v

.

Refill boiler to normal water line. If water

in gauge glass does not appear to be

clear, repeat steps

(

i.

thru

iii.

)

and boil

out the boiler for a longer time.

b. Low pressure steam boilers such as the

MegaSteam™, should be maintained with

appropriate water treatment compounds.

Add suitable water treatment compounds

as recommended by your qualified water

treatment company.

c. Remove temporary surface blow-off piping,

plug tapping and reinstall safety valve.

Boil or bring water temperature to 180°F

promptly in order to drive off the dissolved

gases in the fresh water.

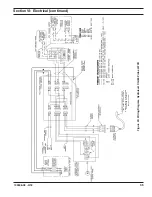

d. If unsteady water line, foaming or priming

persist, install gate valve in Hartford Loop

and drain valves in return main and at boiler

as shown in Figure 11 and proceed as

follows:

i.

Connect hoses from drain valves to floor

drain. Close gate valve in Hartford Loop

and open drain valve in return main. Fill

boiler to normal water level, turn on oil

burner and operate boiler at this water

level for at least 30 minutes after the

condensate begins to run hot, then turn

off burner.

Close all radiator valves. Remove all

supply main air valves and plug the

openings in supply main.

ii.

Draw about 5 gallons of hot water from

boiler into a container and dissolve

into it the appropriate amount of a

recommended boilout compound.

Remove safety valve from boiler and

pour this solution into boiler, then

reinstall safety valve.

iii.

Turn on oil burner and keep operating

while feeding water to boiler slowly. This

will raise water level in boiler slowly so

that water will be boiling hot and will

rise slowly into supply main and back

through return main, flowing from drain

hose at about 180°F. Continue until

water runs clear from drain hose for at

least 30 minutes.

iv.

Stop feeding water to boiler but

continue operating oil burner until

excess water in boiler flows out through

supply main and water lowers (by

steaming) until it reaches normal level

in boiler. Turn off oil burner. Drain boiler.

Open all radiator valves. Reinstall all

supply main air valves. Open gate valve

in Hartford Loop.

v.

When boiler has cooled down

sufficiently (crown sheet of sections are

not too hot to touch), close the drain

valves at boiler and in return main and

feed water slowly up to normal level

in boiler. Turn on oil burner and allow

boiler to steam for 10 minutes, then turn

off burner. Draw off one quart of water

from bottom gauge glass fitting and

discard. Draw off another quart sample

and if this sample is not clear, repeat

the cycle of draining the boiler and

return main and refilling the boiler until

sample is clear.

vi.

If the boiler water becomes dirty

again at a later date due to additional

sediment loosened up in the piping,

close gate valve in Hartford Loop, open

drain valve in return main, turn on oil

burner and allow Condensate to flow to

drain until it has run clear for at least 30

minutes while feeding water to boiler so

as to maintain normal water level. Turn

off oil burner, drain boiler, open gate

valve in Hartford Loop, then repeat Step

1 above.

NOTICE

Check with local authorities or

consult local water treatment services for

acceptable chemical cleaning compounds.

Section IX: Maintenance and Service Instructions (continued)

Summary of Contents for MegaSteam MST288

Page 54: ...54 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 56: ...56 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 58: ...58 103536 08 4 18 Jacket Assembly Section XII Repair Parts continued...

Page 62: ...62 103536 08 4 18 Beckett AFG Burner Section XII Repair Parts continued...

Page 65: ...65 103536 08 4 18...

Page 66: ...66 103536 08 4 18...

Page 67: ...67 103536 08 4 18...