19

103536-08 - 4/18

Section II: Unit-Pak Boiler Assembly (continued)

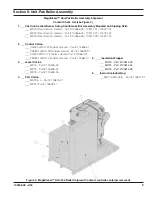

M. PROBE LWCO (HYDROLEVEL CG450,

OR, MCDONNELL-MILLER PSE801-120)

INSTALLATION.

1. Remove either Hydrolevel CG450 LWCO with

factory attached harness and Hydrolevel probe

#EL1214, or, McDonnell-Miller PSE801-120

with factory attached harness and #153875

probe from Control Carton.

2. Install the probe into the appropriate front

section tapping. See Figure 7 “Purpose of

Tappings & Bosses”.

3. Slip LWCO with factory attached harness

over the probe and clamp in place. Note that

CG450 LWCO will be positioned right side up,

with diagnostic LED(s) on the top flange, while

PSE801 LWCO will be positioned upside down,

with diagnostic LED(s) on the bottom flange.

Connect the wire(s) between the probe and

control per manufacturer’s instructions.

4. Pick-up the LWCO harness Molex end and

feed it into the enclosure, thru external

electrical enclosure top flange front left 7/8”

hole; then, snap-in harness BX connector

into the hole, and, plug-in Molex connector

into dedicated LWCO receptacle inside the

enclosure (middle left off transformer/relay).

See “ Control Plug-In Diagram” label attached

to inside of the enclosure cover for details

.

N. PRESSURE GAUGE AND GAUGE GLASS

INSTALLATION.

1. Remove the 6” water gauge glass set from Part

Carton.

2. Install the gauge glass using the two ½” NPT

tappings to the right of the probe LWCO. See

Figure 7 “Purpose of Tappings & Bosses”.

3. Thread the pressure gauge into 1/4” NPT

tapping of the front section. See Figure 7

“Purpose of Tappings & Bosses”. Tighten with

wrench applied to the square shank of the

gauge.

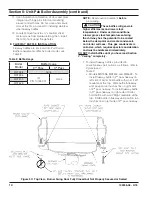

O. AQUASTAT CONTROLLER INSTALLATION

(BOILERS WITH TANKLESS HEATER ONLY).

1. On boilers with tankless heater, install the

L4006A aquastat controller well (found in Part

Carton) into ½” NPT tapping in tankless heater

plate.

2. Remove the L4006A aquastat controller with

factory attached harness from Control Carton.

Do not apply pressure to

gauge case, as this may result in inaccurate

readings.

CAUTION

3. Slip the bulb of the aquastat controller into the

well and secure the controller in place with the

set screw.

4. Feed the L4006A aquastat controller harness

end thru external electrical enclosure top

flange middle right bushed hole. See “ Control

Plug-In Diagram” label attached to inside of

the enclosure cover for details.

5. See Figures 21 thru 21B (whichever

applicable) for tankless heater aquastat

connection details.

6. Using needle nose pliers form hook on

harness each stripped end and wrap hooks

around screws under terminals "R" and "G" of

the R8285C Transformer-Relay; then, tighten

screws securely.

P. SAFETY VALVE AND DRAIN VALVE

INSTALLATION.

1. Remove safety valve and related piping (3/4”

NPT x 3” lg. black nipple, 3/4” NPT x 8” lg.

black nipple, ¾” NPT 90° black elbow and ¾”

NPT black coupling) from Part Carton.

2. Thread 3/4" NPT x 3” lg. black nipple into rear

section safety valve tapping, install ¾” NPT 90°

black elbow facing upward, then, thread 3/4"

NPT x 8” lg. black nipple into the elbow, and,

install ¾” NPT black coupling onto nipple end.

3. Thread safety valve into the ¾” NPT black

coupling. Pipe the safety valve discharge as

shown in Figure 11 “ Recommended Boiler

Piping For Gravity Return Steam Boiler” shown

in Section III of this manual. Installation of the

safety valve must be consistent with ANSI/

ASME Boiler and Pressure Vessel Code,

Section IV.

4. Remove 1-1/2" NPT x 5” lg. black nipple, 1-1/2”

x 1-1/2” x ¾” NPT black tee and drain valve

from Part Carton.

Aquastat bulb must be fully

inserted into the well.

WARNING

Safety valve discharge piping

must be piped near floor to eliminate potential

of severe burns. Do not pipe in any area where

freezing could occur. Do not install any shut-

off valves, plugs or caps.

WARNING

NOTICE

Lower rear section Tapping "H" is

used for standard condensate return on steam

boilers.

Summary of Contents for MegaSteam MST288

Page 54: ...54 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 56: ...56 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 58: ...58 103536 08 4 18 Jacket Assembly Section XII Repair Parts continued...

Page 62: ...62 103536 08 4 18 Beckett AFG Burner Section XII Repair Parts continued...

Page 65: ...65 103536 08 4 18...

Page 66: ...66 103536 08 4 18...

Page 67: ...67 103536 08 4 18...