39

103536-08 - 4/18

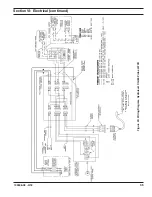

Figure 23: Single Pipe Oil Line

A.

GENERAL

1. Use flexible oil line(s) so the burner swing door

can be opened without disconnecting the oil

supply piping.

2. A supply line fuel oil filter is recommended as a

minimum for all firing rates but a pleated paper

fuel oil filter is recommended for the firing rates

below 1.0 gph to prevent nozzle fouling.

3. Use Flared fittings only. Cast iron fittings

cannot be used.

4. Use of a high efficiency micron filter (Garber or

equivalent) in addition to a conventional filter is

highly recommended.

5. Piping used to connect the oil burner to the oil

supply tank shall not be smaller than 3/8" iron

pipe or 3/8" OD copper tubing. Copper tubing

shall have a .032" minimum wall thickness.

B.

SINGLE PIPE OIL LINES

1. Standard burners are provided with single-

stage 3450 rpm fuel units with the bypass plug

removed for single-pipe installations.

2. The single-stage fuel unit may be installed

single-pipe with gravity feed or lift. Maximum

allowable lift is 8 feet. See Figure 23.

3. Fuel Oil Line Deaerator – On many occasions

a leaky oil delivery line can introduce air

into the fuel oil supply system. This often

creates a rough starting condition and can

create a burner lockout state. In addition to

fixing the leak, a fuel line deaerator can be

installed to eliminate air. The single line from

the fuel tank is connected to the deaerator.

The burner pump must be connected to the

deaerator as a two pipe system. Follow the

oil pump manufacturer’s recommendations for

conversion to a two pipe system.

NOTICE

Do not use compression fittings.

Oil piping must be absolutely airtight or leaks

or loss of prime may result. Bleed line and

fuel unit completely.

Refer to your local jurisdictions regarding

any special considerations for fuel supply

requirements. In addition, refer to NFPA 31,

Standard for the installation of Oil-Burning

Equipment.

Under no circumstances can

copper with sweat style connectors be used.

WARNING

NOTICE

Some jurisdictions require the use of

a fusible shutoff valve at the tank and/or the

burner. In addition, some jurisdictions require

the use of a fusible electrical interlock with

the burner circuit. Check your local Codes for

special requirements.

•

•

Section VII: Oil Piping

Summary of Contents for MegaSteam MST288

Page 54: ...54 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 56: ...56 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 58: ...58 103536 08 4 18 Jacket Assembly Section XII Repair Parts continued...

Page 62: ...62 103536 08 4 18 Beckett AFG Burner Section XII Repair Parts continued...

Page 65: ...65 103536 08 4 18...

Page 66: ...66 103536 08 4 18...

Page 67: ...67 103536 08 4 18...