18

103536-08 - 4/18

over four #8 x ½” shoulder sheet metal screws,

previously installed at Front and Rear Jacket

Panel side flanges, so teardrop cutouts in

the side panel inside flanges engage all four

screws simultaneously.

7. Slide the panel downwards to lock all screws

securely.

8. Pick up Top Jacket Panel from Jacket Carton.

9. Place the panel between side panels upper

inside flanges and slide it forward, until top

panel front flange U-bend locks over front

panel top flange, and, top panel rear flange is

positioned over rear jacket panel.

10. Locate/remove two #8 x ½” sheet metal screws

from Hardware Bag.

11. Install both screws into top panel rear flange to

secure the top panel to rear jacket panel.

K. EXTERNAL ELECTRICAL ENCLOSURE

MOUNTING.

1. Remove two #8 x ½” shoulder sheet metal

screws and one #8 x ½” sheet metal screw

from Hardware Bag.

2. Install both #8 x ½” shoulder sheet metal

screws into Right Side Jacket Panel, at two

upper corners of the panel front cutout.

3. Locate and remove External Electrical

Enclosure assembly from Control Carton.

4. Remove the enclosure cover and set aside.

5. Pick Molex connector end of Burner Harness

and feed it inside the enclosure, thru bushed

hole at enclosure lower left corner, next to

transformer/relay.

6. Place the enclosure over installed shoulder

sheet metal screws, so teardrop cutouts in

the enclosure base engage both screws

simultaneously, then, slide the enclosure

downwards to lock it in place.

7. Install #8 x ½” sheet metal screw thru

enclosure base lower hole, located to the right

of transformer/relay, into right side panel to

secure the enclosure.

8. Plug-in burner harness Molex connector into

dedicated burner harness receptacle inside

the enclosure (lower left off transformer/relay).

See “ Control Plug-In Diagram” label attached

to inside of the enclosure cover for details.

9. Do not install the enclosure cover yet; proceed

to control installation.

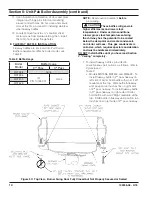

Figure 8: Pressure Limit Installation

L. TRIM AND CONTROLS INSTALLATION.

Pressure Limit Installation.

1. Locate and remove L404F Pressure Limit with

factory attached harness from Control Carton.

2. Locate and remove 1/4" NPT x 1-7/8" x 4 x 90°

syphon enclosed in Part Carton.

3. Review and locate pressure limit tapping

on front section. See Table 3 “ Purpose of

Tappings & Bosses” and Figure 7.

4. Thread 1-7/8" lg. syphon-threaded short end

into the bottom of Pressure Limit with factory

attached harness. Do not tighten the syphon

by holding the limit case; apply a wrench to the

brass hex below the case.

5. Thread ¼" NPT x 4" lg. syphon-threaded long

end into pressure limit tapping on front section.

See Figure 8 "Pressure Limit Installation.

Section II: Unit-Pak Boiler Assembly (continued)

6. L404F pressure limit does not require leveling.

The pressure limit final orientation must be

parallel to boiler front, having the harness on

the right side.

7. Pick-up the pressure limit harness Molex end

and feed it into the enclosure, thru top flange

rear left 7/8” hole; then, snap-in harness BX

connector into the hole, and, plug Molex

connector into dedicated pressure limit

receptacle inside the enclosure (upper left

off transformer/relay). See “ Control Plug-

In Diagram” label attached to inside of the

enclosure cover for details.

Summary of Contents for MegaSteam MST288

Page 54: ...54 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 56: ...56 103536 08 4 18 Bare Boiler Assembly Section XII Repair Parts continued...

Page 58: ...58 103536 08 4 18 Jacket Assembly Section XII Repair Parts continued...

Page 62: ...62 103536 08 4 18 Beckett AFG Burner Section XII Repair Parts continued...

Page 65: ...65 103536 08 4 18...

Page 66: ...66 103536 08 4 18...

Page 67: ...67 103536 08 4 18...