Dealer Instructions 11

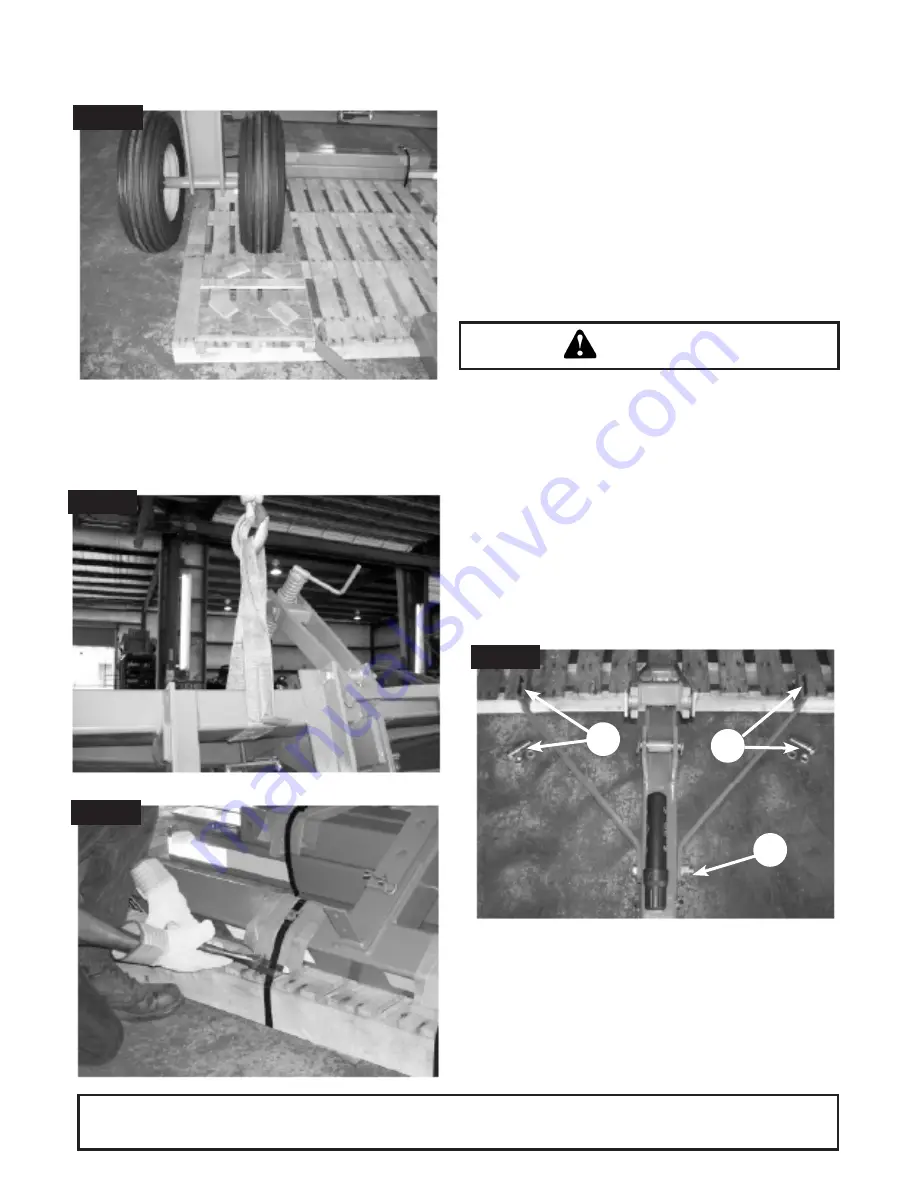

ing on pallet (Photo 10). Use the two small pal-

lets, shipped with unit, as chocks for the wheels

on the wheel carriage (Photo 11). This will keep

the frame from rolling off the pallet and cause-

serious injury or death. While the frame is rest-

ing on the pallet, relocate the sling from its cur-

rent location to the main bar (6x4 tube) on front

of frame (Photo 12). This will allow you to attach

the leveling assembly without interference in a

later step. Once sling has been relocated, con-

nect to overhead hoist and raise hoist until

slack has been removed from sling.

When completing this portion of the assembly

process, be careful handling the large parts.

The components are heavy and dropping them

could lead to serious injury or death.

Keep slight upward pressure on front of frame

and cut bands connecting the rear of frame to

the pallet (Photo 13). When all bands have

been cut, lower the frame to the tongue lying on

the ground. Down pressure may need to be

applied to frame in order for the frame to come

down. Connecting the tongue to the frame will

be the next step in assembly. The two 7/8” x 6

½” Gr. 5 bolts removed from an earlier step

(Photo 4) will be needed for this process. Once

frame has been lowered to the pallet, remove

the two 7/8” x 3 ½” Gr. 5 bolts from the tongue

Bolt Torque Chart (Page 45) for proper torque

information.

Before unit can be lowered to pallet, remove the

bracing the wheel carriage was resting on when

shipped (Photo 9). When bracing has been

removed, lower frame so that wheels are rest-

Photo 11

Photo 12

WARNING

Photo 13

Photo 14

2

1

1

Summary of Contents for MVT1710

Page 1: ...MVT17_16154_06 2018 VT1710 VT1713 VT1712 VT1715 VERTICAL TILLAGE O P E R A T O R S M A N U A L...

Page 23: ...Dealer Instructions 20...

Page 24: ...Operation 21 45 3 8 3 8...

Page 29: ...Owner Service 26...

Page 31: ...Assembly Schematic 28 DUAL WHEELS ARE STANDARD ON ALL MODELS MVT Assembly Schematic Figure 3...

Page 48: ...Bolt and Torque Chart 45 MVT Series gang bolt torquee 350lbs ft then tighten nut clockwise 180...

Page 49: ...Notes 46 Notes...

Page 50: ...2018 Monroe Tufline Manufacturing Inc All Rights Reserved PART NO 16154...