10

Exhaust gas cowl

The heater is only approved when used with a roof cowl.

This must be installed vertically or with no more than a

15 degree slope!

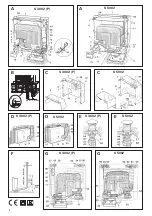

Fig. F:

Position the roof cowl so that the duct (minimum

length 1.5 m, maximum length 3 m) can be routed direct from

the heater unit, sloping upward all the way to the cowl. A

1.5 metre long duct must reach a height of at least 1 metre.

The remain der of the duct to the roof cowl must be installed

more or less vertically.

Trumatic S 3002 (P)

Fig. E:

Cut out an opening with a Ø of 60 mm at a centre dis-

tance of at least 55 mm from the side walls.

Trumatic S 5002

1. Fig. E:

Cut out an opening with a Ø of 70 mm at a centre

distance of at least 60 mm from the side walls.

2 Fig. E:

In the case of a double-skin roof, line the cavity with

wood or slide in a rolled circular sheet metal strip (20) of about

220 mm in length and 1 mm in thick ness, to stiffen the roof so

that when the screws are tightened it does not warp and stays

weatherproof.

3. Fig. E:

Push the cowl through the roof from above and

fasten it on the inside with screw ring (21). Next, secure the

screw ring (21) with a screw (44).

Use the enclosed rubber sealing ring without further sealing

materials.

Exhaust duct

For the Trumatic S, only the Truma stainless-steel waste gas

pipe AE 3 or AE 5 with the Truma pipe sheath UR or UR 5 (APP)

may be used, since the devices have only been tested and ap-

proved in conjunction with these pipes.

Length of exhaust duct: min. 1.5 m, max. 3 m!

Fitting and bending the stainless steel duct and stretch-

ing open the O-ring are made considerably easier by using

“Biege-Boy“ (part no. 30030-33000).

1. Connecting the exhaust duct to the heater:

Slide sealing plate (22) about 3 cm onto the exhaust duct

(with the claw pointing towards the heater exhaust outlet).

Slide on pressure ring (25). Stretch open O-Ring (23) and

carefully pass it over the cut edge of the duct. Then plug the

exhaust duct into the exhaust outlet as far as the stop.

Slide the O-ring, pressure ring and sealing plate to the exhaust

outlet. Twist on sealing plate (22) and fasten it securely by

tightening screw (24).

A new O-ring (23) must be fitted each time the

exhaust duct is dismantled.

2. Slide insulating duct (41) onto the exhaust duct (it must

reach from the cowl to the rear wall of the installation box,

refer to fig. E + D).

3. Fig. D + E:

Take the ducting up the wall with as few bends

as possible. Slide exhaust gas duct (40) into the cowl as far as

the stop and secure with self-tapping screw (28).

The flue gas pipe (40) with insulating duct (41)

must be ascending along its entire length and se-

curely and permanently installed

using several clamps

(42),

since otherwise a water pocket may form that will

prevent the flue gas from exiting freely.

Gas connection

Fig. A (e):

The gas supply’s operating pressure (30 mbar)

must be the same as the unit´s operating pressure (see type

plate).

Fig. G:

The gas supply pipe (32) must be connected using a

cutting ring screw fitting with an outer diameter of 8 mm at

the connecting piece (33).

The gas connection fitting on the heating appli-

ance must not be bent!

When tightening the connec-

tion nipple, hold it carefully in place with a second wrench!

Route the ducting in such a way that the heater can be re-

moved for servicing work.

Make sure the gas lines are free of dirt, chips and such prior

to connecting!

A special duct for internal gas connection is available on re-

quest. It is screwed onto gas connection fitting (33) with an

elbow.

The gas system must accord with the technical and adminis-

trative provisions of the individual country of use (in Europe,

for example, EN 1949 for motor vehicles).

National regulations and rulings (in Germany, for example,

the DVGW worksheet G 607 for motor vehicles) must be

respected.

Heater casing

1. Fig. G:

Push the handle connector (26), the piezo pressure

igniter (27) if applicable, and the integrated operating element

(51) for the Trumavent TEB fan into the cut-outs (take care to

respect right-hand or left-hand installation!). Close off any un-

occupied cut-outs with the closure cover (50).

For Trumatic S 3002 P only

Plug the earthing cable (34) to the pressure igniter (27) and

the earth contact (37) on the casing.

2. Press type plate (52) into the observation window opening

(note right-handed or left-handed installation!).

3. With integrated control panel (51) plug connecting cable

(53) of the Trumavent fan TEB into the control panel. Bend

back strap (54) on the installation box and insert connecting

cable (53).

For Trumatic S 3002 P only

Slide flat connector of ignition cable (38) on the connection

(36) on the piezo ignitor (27) and slide on insulation (43 – refer

to fig. A).