9

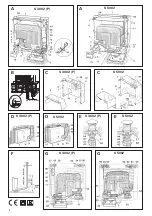

2. Fig. C:

Slide heater to the rear spacer brackets (18) in the

installation box.

3. Fig. A:

Fasten heater with 5 screws (3) to the pre-drilled

points in the corners and at the front in the center. If neces-

sary, reinforce the floor structure with battens.

4. Fig. A:

Press ground spring (30) out of the transportation

safety device so that it rests against the installation box (other-

wise the ignition will not work).

5. Fig. A:

Insert push rod with eye spring (11) into the ignition

safety valve (12).

Fasten ignition cable (38) on the side of the push rod in the

3 retaining straps (39) of the installation box.

Trumatic S 3002

1. Fig. A:

Place the heater unit in the floor opening. Plug the

thermostat probe with the screening plate (7) in the slot (8)

and slide it under the attachment piece (9) until you hear it

engage (fig. A shows right-handed installation, fig. G shows

left-hand installation).

The thermostat probe (7) and automatic ignitor (15)

must always be at the front of the heater (facing the

room). The thermostat probe (7) and the capillary tube (10)

must never touch the heat exchanger or the heater casing!

2. Fig C:

Slide heater to the rear spacer brackets (18) in the

installation box.

3. Fig A:

Remove automatic ignitor (15) from its mount. Fas-

ten heater with 5 screws (3) to the pre-drilled points in the

corners and at the front in the center. If necessary, reinforce

the floor structure with battens.

4. Check the automatic ignition device (15) to ensure that the

plug-in connections (13 + 14) are mounted properly. Then

push the automatic ignition device (15) into the link plates (16)

as far as the stop (fig. A shows right-hand installation, fig. G

shows left-hand installation).

5. Fig. A:

Insert push rod with eye spring (11) into the ignition

safety valve (12).

Trumatic S 5002

When installing a Trumatic S 5002 heater starting from

date of manufacture 05/98 as a replacement for a

Trumatic S 5002 heater up to date of manufacture 05/98,

Truma supplies an additionally required assembly-cover set

(please ask your dealer).

1. Fig. A:

Place the heater unit in the floor opening. Insert the

thermostat probe (7) with screening plate into strap (8) and

fasten it with self-tapping screw (9). (Fig. A shows right-hand

installation, fig. G shows left-hand installation.)

Thermostat probe (7) and automatic ignitor (15) must al-

ways be at the front of the heater (facing the room).

Thermostat probe (7) and capillary tube (10) must never be al-

lowed to touch the heat exchanger or heater casing!

2. Fig A:

Remove automatic ignitor (15) from its holder.

Fasten the heater by means of the 5 screws (3 – holes are

pre-punched in the corners and front centre). If necessary, re-

inforce the floor structure with battens.

3. Check the automatic ignition device (15) to ensure that the

plug-in connections (13 + 14) are mounted properly. Then

push the automatic ignition device (15) into the link plates (16)

as far as the stop (fig. A shows right-hand installation, fig. G

shows left-hand installation).

4. Fig. A:

Insert push rod with eye spring (11) into ignition

safety valve (12). Insert control knob (55) onto push rod (11)

so that the arrow points to „0” (heater middle position).

The plinth or false floor must be sealed from the vehi-

cle interior and must be made from a non-flammable

material

or lined on the inside with sheet metal because of

the

risk of blow-back

under unfavourable wind conditions.

To prevent non-burned gas from building up the plinth

must have a vent

at least 2 cm² in size

at its lowest point,

or must be open at the bottom.

5. Exhaust ducts and cowls must be installed in such

a way that exhaust gas cannot find its way into the

vehicle.

To ensure even and rapid warm air distribution as well as

lower surface tem peratures on the heating unit, we rec-

ommend installing a Trumavent warm-air system.

If desired, the Trumatic S 5002 heating system is also

available with a special installation box for two

Trumavent fans.

Preparatory work and installation boxes

1. Secure the template for the floor opening in the cut-out

section by means of thumb tacks, the arrow must point exact-

ly to the front edge of the opening (R = right-hand installation,

L = left-hand installation).

2. Cut the floor opening using a saw and pre-drill 5 holes

for the fixing screws.

The exact dimensions must be

observed!

3. Fig. A:

Insert half-frames (5) in the floor opening and press

them outwards and screw tight (pretension as needed by

bending the sides upward so that the frame fits firmly).

4. Fig. D:

Break out the pre-stamped apertures for the waste

gas pipe on the outer part of the installation box (R = right-

hand installation, L = left-hand installation). If the installation

depth is small, the waste gas pipe can also be conducted

through the side with the S 5002 heating system (R1 or L1).

When installing the special pipe for internal gas connection

(refer to “Gas connection”), break out both apertures.

If a Trumavent fan and / or Truma Ultraheat electrical

supplementary heating are being fitted, remove the pre-

stamped cover (T) or (U) respectively, and fit the units to the

installation box in accordance with the installation instructions

provided in each case.

5. Fig. C:

Separate the outer part (1) and inner part (2) of

the installation box, and secure them with 5 sheet metal

screws (19).

For the S 5002 heating system, the screws (19a) must

be used for right-hand installation and the screws (19b)

for left-hand installation.

Firmly screw in the 3 screws (35), even if you are not installing

a Trumavent fan.

6. Place the pre-assembled installation box in the opening and

screw at an angle to the outside using 6 bolts (6) respectively.

Installation of the heater

Trumatic S 3002 P

1. Fig. A:

Place the heater unit in the floor opening. Plug the

thermostat probe with the screening plate (7) in the slot (8)

and slide it under the attachment piece (9) until you hear it

engage (fig. A shows right-hand installation, fig. G shows left-

hand installation).

The thermostat probe (7) must always be at the front of

the heater (facing the room). Thermostat probe (7) and

the capillary tube (10) must never touch the heat exchanger or

the heater casing!