Intelligent Gyro Compass (iGC)

0707-SOM-00004-7

31

© Tritech International Ltd.

8. Maintenance

8.1. Safety

Before commencing installation of the iGC:

1. Refer to Chapter 1,

2. All relevant parts of this section of the manual should be read and understood

8.2. General

The iGC is designed for low maintenance operation using corrosion resistant materials, and

generally speaking does not require any preventative maintenance.

In addition there are no user serviceable parts inside the iGC.

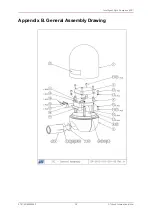

8.3. Seals

Seal integrity is vital for the continued reliability of the iGC. There are two ‘O’-ring seals in

the assembly – one between the dome and end-cap and the other between the Subconn

connector and end-cap. The following should be noted:

1. Any time that a seal is disturbed, before replacement in the iGC it should be thoroughly

cleaned and inspected for damage

2. The seal housing should be thoroughly cleaned and inspected for damage

3. Any damaged seals or components with damaged sealing faces should be replaced with

new components

4. All replacement seals should be correctly specified as per the iGC parts lists

5. Never use ‘O’-rings made up by gluing cord to the correct length

6. When replacing an ‘O’-ring, use an approved ‘O’-ring grease (such as Dow Corning 111

silicone compound) sparingly and make sure that all surfaces are kept clean during the

process of replacement

7. The ‘O’-rings fitted to the iGC have a recommended service life of seven years

8. Spare ‘O’-rings should be stored in suitable UV light proof bags or containers

8.4. Basic Maintenance Procedure

8.4.1. Pre and Post Dive Checks

1. Check that the interconnecting cable is secure and undamaged