68

OAU-SVX006E-EN

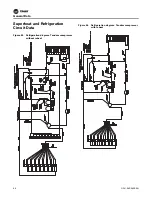

Alarms and Troubleshooting

Microprocessor Control

The Main Unit Display and RTRM have the ability to

provide the service personnel with some unit diagnostics

and system status information.

1. Verify that the Liteport LED on the RTRM is burning

continuously. If the LED is lit, go to

.

2. If the LED is not lit, verify that 24 Vac is presence

between J1-1 and J1-2. If 24 Vac is present, proceed to

. If 24 Vac is not present, check the unit main

power supply, check transformer (TNS1). Proceed to

if necessary.

3. Utilizing “Method 1” in the RTRM “System Status

Checkout Procedure”, check the following:

•

System status

•

Cooling status

If a System failure is indicated, proceed to

. If no

failures are indicated, proceed to

4. If a System failure is indicated, recheck

, and 24 Vac is present in

, the RTRM has failed. Replace the RTRM.

5. If no failures are indicated, use one of the override

options to start the unit. Following the Override

procedure will allow you to check all of the operating

modes, and all of the external controls (relays,

contactors, etc.) for each respective mode.

6. Refer to the sequence of operations for each mode, to

assist in verifying proper operation. Make the

necessary repairs and proceed to

7. If no abnormal operating conditions appear in the

Override mode, release the override and turn the

power “Off” at the main power disconnect switch.

System Alarms

The Main Unit Display has built in alarms to help the

operator troubleshoot system failures. This section will

describe these alarms and provide a guide to

troubleshooting the all unit operating modes.

Comprehensive system alarms and diagnostics are

accessed through the Alarms icon at the unit display

discussed later in the section, or through Tracer TU

programming on connected computer. Sensor failures

may be viewed through the Alarms icon.

If an alarm is present, the main indicator light on the

UC600 will blink red. If the optional unit display is installed,

the Alarm icon on the display will register ALARM,

illuminate red and flash.

Important:

The space temperature sensor (SPTC) and

space relative humidity sensor (SPHC) will

read failed if they are not connected; they

will Alarm as “In Fault.”

Sensor Failure Alarm Display

Press the Alarm button on the Home display of the Unit

Display to display system sensor status as described in

.

WARNING

Hazardous Service Procedures!

Failure to follow all precautions in this manual and on

the tags, stickers, and labels could result in death or

serious injury.

Technicians, in order to protect themselves from

potential electrical, mechanical, and chemical hazards,

MUST follow precautions in this manual and on the

tags, stickers, and labels, as well as the following

instructions: Unless specified otherwise, disconnect all

electrical power including remote disconnect and

discharge all energy storing devices such as capacitors

before servicing. Follow proper lockout/tagout

procedures to ensure the power can not be

inadvertently energized. When necessary to work with

live electrical components, have a qualified licensed

electrician or other individual who has been trained in

handling live electrical components perform these

tasks.

AVERTISSEMENT

Procédures d’entretien dangereuses!

Le non-respect de toutes les précautions contenues

dans ce manuel ainsi que sur les étiquettes et les

autocollants peut entraîner des blessures graves voire

mortelles.

Les techniciens, afin d’être protégés des éventuels

risques électriques, mécaniques et chimiques,

DOIVENT suivre les précautions contenues dans ce

manuel, sur les étiquettes et les autocollants, ainsi que

les instructions suivantes : Sauf indication contraire,

coupez toute l’alimentation électrique y compris les

disjoncteurs à distance et déchargez tous les dispositifs

de stockage d’énergie comme les condensateurs avant

l’entretien. Respectez les procédures de verrouillage et

d’étiquetage appropriées pour éviter tout risque de

remise sous tension accidentelle. S’il est nécessaire de

travailler avec des composants électriques sous

tension, demandez à un électricien qualifié et agréé ou

à une autre personne ayant la formation nécessaire

pour manipuler des composants électriques sous

tension d’exécuter ces tâches.