Cleaning the Condenser

D

NOTICE

Proper Water Treatment!

The use of untreated or improperly treated water in a

CenTraVac could result in scaling, erosion, corrosion,

algae or slime. It is recommended that the services of

a qualified water treatment specialist be engaged to

determine what water treatment, if any, is required.

Trane assumes no responsibility for equipment

failures which result from untreated or improperly

treated water, or saline or brackish water.

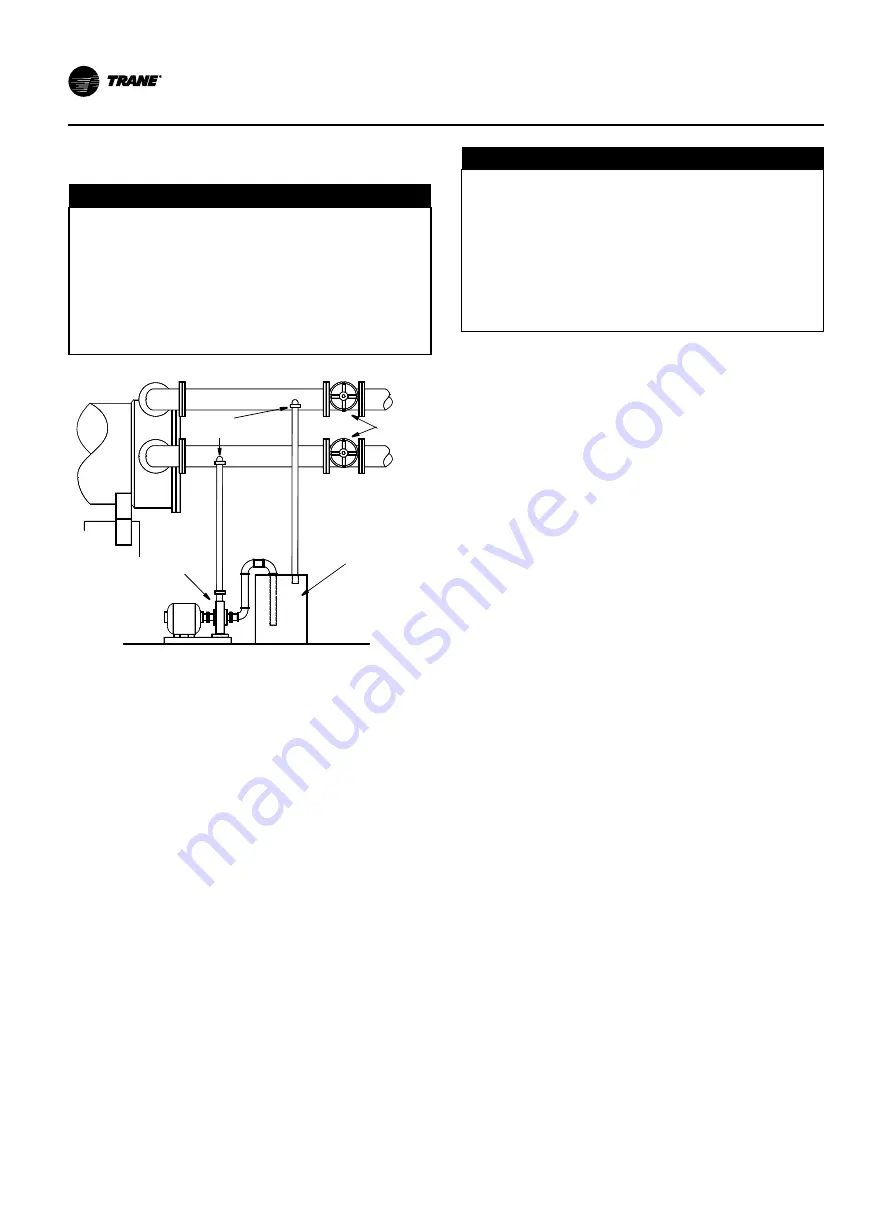

Figure 35. Typical Chemical Cleaning Setup

pipe

connections

pump

circulator

cleaning

solution

shutoff

valves

Condenser tube fouling is indicated when the approach

temperature (the difference between the condensing

refrigerant temperature and the leaving condenser water

temperature) is higher than predicted.

If the annual condenser tube inspection indicates that

the tubes are fouled, two cleaning methods, mechanical

and chemical, can be used to rid the tubes of contami-

nants. Use the mechanical cleaning method to remove

sludge and loose material from smooth-bore tubes.

To clean other types of tubes including internally-en-

hanced types, consult a qualified service organization for

recommendations.

1. Follow all instructions in

to remove waterbox covers.

2. Work a round nylon or brass bristled brush (attached

to a rod) in and out of each of the condenser water

tubes to loosen the sludge.

3. Thoroughly flush the condenser water tubes with

clean water.

Scale deposits are best removed by chemical means.

Be sure to consult any qualified chemical house in the

area (one familiar with the local water supply’s chemical

mineral content) for a recommended cleaning solution

suitable for the job. Remember, a standard condenser

water circuit is composed solely of copper, cast iron and

steel.

D

NOTICE

Unit Corrosion Damage!

Proper procedures must be followed when using

corrosive chemicals to clean water side of unit. It is

recommended that the services of a qualified chem-

ical cleaning firm be used. Proper personal protec-

tive equipment as recommended by the chemical

manufacturer should be used. Refer to the chemicals

MSDS sheet for proper safety procedures. Failure to

follow proper procedures could result in corrosion

damage to the unit and tubes.

Important:

All of the materials used in the external

circulation system, the quantity of the solu-

tion, the duration of the cleaning period,

and any required safety precautions should

be approved by the company furnishing

the materials or performing the cleaning.

Remember, however, that whenever the

chemical tube cleaning method is used, it

must be followed up with mechanical tube

cleaning, flushing and inspection.

Cleaning the Evaporator

Since the evaporator is typically part of a closed circuit,

it may not accumulate appreciable amounts of scale or

sludge. Normally, cleaning every three years is sufficient.

However, on open evaporator systems, such as air wash-

ers, periodic inspection and cleaning is recommended.

Purge System

Because some sections of the chiller’s refrigeration

system operate at less-than-atmospheric pressure, the

possibility exists that air and moisture may leak into the

system. If allowed to

accumulate, these noncondensables become trapped

in the condenser; this increases condensing pressure

and compressor power requirements, and reduces the

chiller’s efficiency and cooling capacity.

The Trane EarthWise Purge is the only purge system

available for the CenTraVac chiller. The purge is designed

to remove noncondensable gases and water from the

refrigeration system. EarthWise Purge unit operation,

maintenance and trouble shooting is covered by a sepa-

rate operation and maintenance manual, which may be

obtained from the nearest Trane office.

Leak Checking Based on Purge Pump Out

Time

A formula has been developed which allows the annu-

al refrigerant leakage rate to be calculated based on

the daily purge pump out time and the unit refrigerant

charge. This formula is as follows:

% annual leakage rate = [(X min/day)*(0.0001 lb R-123/

min)/(Y lb)]*100

68

RELEASED 10/Mar/2020 06:59:20 GMT