OPERATION

POSITIONING THE TABLE AND WORKPIECE

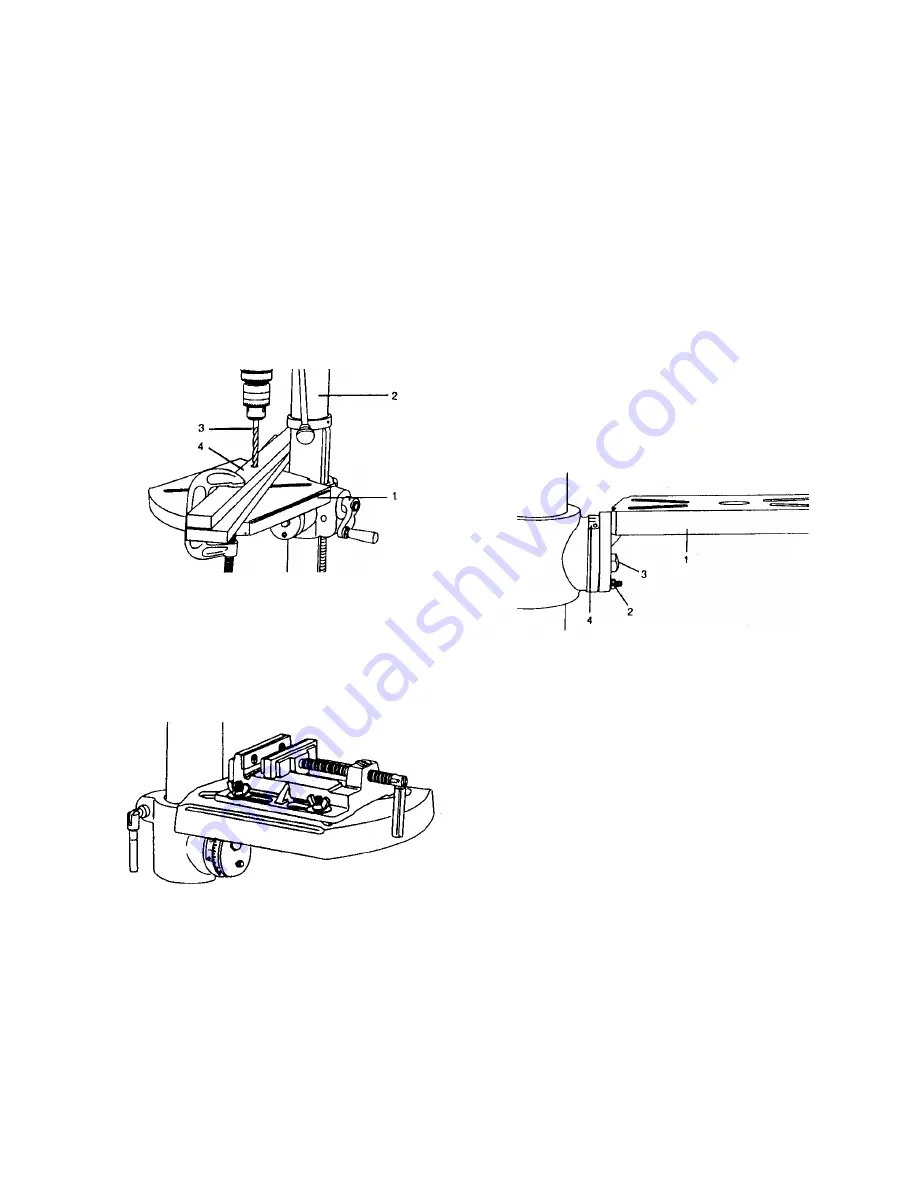

(FIG. 23, 24)

1. Lock the table (1) to the column (2) at a position so the

tip of the drill bit (3) is just above the top of the

workpiece (4).

CAUTION!

To prevent the workpiece or backup material from being

torn from your hands while drilling, you MUST position the

workpiece against the LEFT side of the column. If the

workpiece or the backup material is not long enough to

reach the column, clamp them to the table, or use a vise to

brace the workpiece. Failure to secure the workpiece could

result in personal injury.

Fig. 23

CAUTION!

The drill press vise MUST be clamped or bolted to the table

to avoid injury from a spinning workpiece.

Remove the drill press fence when it interferes with other

drill press accessories.

Fig. 24

HOLDING A DRILLING LOCATION IN METAL

1. Using a centerpunch, make an indentation in the

workpiece where you want the hole.

2. To turn the laser “ON”, press the rocker switch. Using the

feed handles, bring the drill down to align with the

indentation before turning the drill ON.

TILTING THE TABLE (FIG. 25)

NOTE: The table arm and support (1) has a predrilled hole

with a locking set screw inserted for locking the table into a

predetermined 0° horizontal position.

1. To use the table in a bevel (tilted) position, turn the

locking set screw (2) with the hex key counterclockwise

to release it from the table support.

2. Loosen the large hex head bevel locking bolt (3).

CAUTION!

To prevent injury, be sure to hold the table & table arm

assembly, so it will not swivel or tilt.

Fig. 25

3. Tilt the table, aligning the desired angle measurement to

the zero line opposite the scale (4). Tighten the bevel

locking bolt.

4. To return the table to its original position, loosen the

bevel locking bolt (3). Realign the bevel scale (4) to the

0° position.

5. Using the hex key, turn the locking set screw (2)

clockwise to seat into the hole..

CAUTION!

To avoid injury from spinning work or possible tool

breakage, always clamp workpiece and backup material

securely to the table before operating the drill press with the

table tilted.

FEEDING

1. Pull down the feed handles with only enough effort to

allow the drill bit to cut.

2. Feeding too slowly might cause the drill bit to burn.

Feeding too rapidly might stop the motor, cause the belt

or drill to slip, or tear the workpiece loose and break the

drill bit.

3. When drilling metal, it may be necessary to lubricate the

drill bit tip with motor oil, to prevent burning the tip.

18

Summary of Contents for DP12LW

Page 7: ...CARTON CONTENTS 7 L M N O ...

Page 22: ...22 ...