Configuration and Parameterization

TR-Electronic GmbH 2016, All Rights Reserved

Printed in the Federal Republic of Germany

Page 80 of 103

TR - ECE - BA - DGB - 0131 - 02

10/31/2018

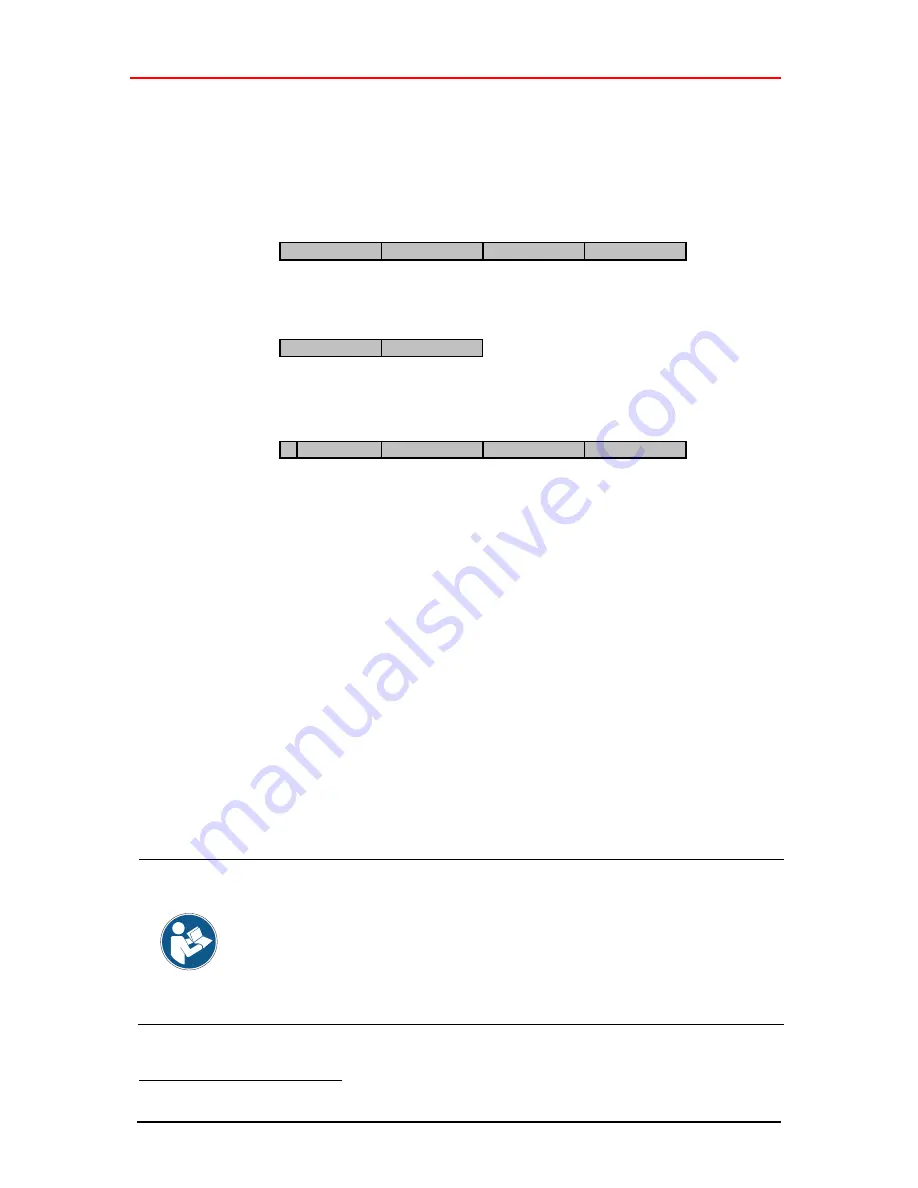

6.2.6 TR-mode pRpm., identifier 0xF1, 0xD0

The measuring system uses two input words for the position plus a separate input word

for the velocity, and two output words which are consistently transferred via the bus. The

velocity is output with a sign in revolutions per minute and has an accuracy of +/- 1 rpm.

Double input word ID x

Data byte 3

Data byte 2

Data byte 1

Data byte 0

LSB

MSB

Input byte x+0

Input byte x+1

Input byte x+2

Input byte x+3

Input word IW x

Data byte 1

Data byte 0

LSB

MSB

Input byte x+0

Input byte x+1

Double output word for preset adjustment OD x

Data byte 3

Data byte 2

Data byte 1

Data byte 0

LSB

MSB

Output byte x+0

Output byte x+1

Output byte x+2

Output byte x+3

P

P = Preset adjustment

Relevant parameter data:

•

Count sequence

•

Commissioning diagnostics

•

Commissioning function

•

Short diagnostics (16 byte)

•

Total measuring range/units

•

Revolutions numerator

•

Revolutions denominator

•

SSI code

4

•

SSI data bit count

•

Profibus code

•

Preset value 1

•

Preset value 2

•

Limit switch lower limit

•

Limit switch upper limit

•

Rpm. multiplier [1/n rpm]

The configurations designated "TR-mode" are not compatible with the PNO encoder

profile in terms of the parameter record. The scaling function prescribed by the PNO

profile is a simple special case of a general gear. Due to the extended 'gear' scaling

function, additional parameters are therefore necessary in order to describe the gear

fully.

In other words, the TR-specific modes represent an extension of the measuring

system function which is not restricted by its compatibility with the PROFIBUS-DP

and certification.

4

SSI on request, no standard