8

Installation Manual

Outdoor Unit

6

Refrigerant piping

CAUTION

Install in rooms that are 5 m

3

or larger. If

a leak of refrigerant gas occurs inside the

room, an oxygen de

fi

ciency may occur.

■

Detaching the Valve cover

Remove the 5 screws.

• Pull the valve cover in the direction of the arrow, and remove it.

Valve cover

■

Refrigerant Piping Connection

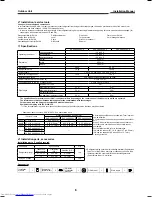

Flaring

1. Cut the pipe with a pipe cutter.

Obliquity

Roughness

Warp

90°

2. Remove the burr inside of the pipe.

When removing the burr, be careful so that chips do not fall into the pipe.

3. Remove the

fl

are nuts attached to the outdoor/indoor unit, then insert them

into each of the pipes.

4. Flare the pipes.

See the following table for the projection margin (A) and

fl

aring size (B).

Die

Pipe

B

A

Pipe

A

B

Flare Nut

Outside

diameter

Thickness

Rigid

(clutch

type)

R410A

tool

Imperial

(wing

nut type)

R410A

tool

Width

across

flat

Tighten

torque

mm

mm

mm

mm

mm

mm

N•m

kgf•m

6.35

0.8

0 to 0.5

1.5 to

2.0

9.1

17

14 to

18

1.4 to

1.8

9.52

0.8

0 to 0.5

1.5 to

2.0

13.2

22

33 to

42

3.3 to

4.2

12.7

0.8

0 to 0.5

2.0 to

2.5

16.6

26

50 to

62

5.0 to

6.2

Pipe connection

1. Make wire and pipe connections for each indoor unit separately.

2. Align the centres of the connecting pipes and tighten the

fl

are nut as much

as possible with your

fi

ngers, then tighten the nut using a torque wrench.

Be sure to tighten the nut at the speci

fi

ed torque value.

• If you use one outdoor unit for several indoor units of a different class,

connect the largest one

fi

rst A, then connect the rest in the order B to C.

• Do not remove the

fl

are nuts for any ports you are not going to use for

connection.

• Do not leave the

fl

are nut unattached for a long period of time.

• Use a different-diameter joint if the diameters of the connection port and

connection piping are different.

• Mount the different-diameter joint on the connection port of the outdoor

unit.

■

Air Purge

From the sake of environmental protection, use a vacuum pump to extract

the air during installation.

* Prepare a 4 mm hexagon wrench.

1. Connect a charge hose.

• Make sure that the Handle Hi of the gauge manifold valve is closed fully.

• Connect the port of the gauge manifold valve and the service port (Valve

core (Setting Pin)) using the charge hose.

NOTE

If a control valve or charge valve is attached to the charge hose, leak

of R410A refrigerant can be avoided.

2. Open the Handle Low of the gauge manifold valve fully, then operate the

vacuum pump.

• Loosen the

fl

are nut of the at the gas end a little to make sure that air is

taken in, then tighten the nut.

• If you

fi

nd air is not taken in, make sure that the charge hose is

connected to the port(s) securely.

• Perform extraction for about 15 or more minutes and make sure that the

compound pressure gauge reading is –101 kPa (–76 cmHg).

• If the compound pressure gauge reading is not –101 kPa (–76 cmHg),

there is a possibility air is being taken in from the port(s).

• Make sure that the charge hose is connected to the port(s) securely.

3. Close the Handle Low of the gauge manifold valve fully, then stop

operating the vacuum pump.

• Leave the gauge and pump as they are for 1 or 2 minutes, then make

sure that the compound pressure gauge reading stays at –101 kPa

(–76 cmHg).

• You need not add refrigerant.

4. Disconnect the charge hose from the service port, then open the valve

stem fully using a 4 mm hexagon wrench.

Hexagon wrench is

required.

Service port cap

Valve stem cap

4 mm

5. Tighten the service valve stem cap and service port cap securely.

CAUTION

Use a torque wrench and tighten the nut at

the speci

fi

ed torque value.

6. Tighten all the caps on the valves securely, then perform a gas leak

inspection.

Service valve

Tighten torque

Valve stem cap

Service port cap

Type

mm

N•m

kgf•m

N•m

kgf•m

Liquid side

6.35

14 to 18

1.4 to 1.8

—

—

Gas side

9.52

14 to 18

1.4 to 1.8

14 to 18

1.4 to 1.8

12.7

33 to 42

3.3 to 4.2

14 to 18

1.4 to 1.8

Service valve at

the liquid side

Service valve at

the gas side

Service port

(Valve core

(Setting pin))

Vacuum pump

Handle Hi

(Keep full closed)

Pressure gauge

Manifold valve

Charge hose

(For R410A only)

Vacuum pump

adapter for counter-

flow preventation

(For R410A only)

Charge hose

(For R410A only)

Compound

pressure gauge

–101 kPa (–76 cmHg)

Handle Low

1116691099_(01) EN.indd 8

1116691099_(01) EN.indd 8

9/22/15 5:59 PM

9/22/15 5:59 PM