6

Installation Manual

Outdoor Unit

2

Installation / service tools

Changes in the product and components

In air conditioners using R410A, in order to prevent any other refrigerant from being accidentally charged, the service port diameter size of the outdoor unit

service valve has been changed. (1/2 UNF 20 threads per inch)

• In order to increase the pressure resisting strength of the refrigerant piping,

fl

are processing diameter and opposing

fl

are nuts sizes have been changed. (for

copper pipes with nominal dimensions 1/2 and 5/8)

Gauge manifold for R410A

Phillips screwdriver

Pipe cutter

Flare tool for R410A

Charge hose for R410A

Level

Torque wrench

4 mm hexagonal wrench

Vacuum pump for R410A

Scale

Wrench (or spanner)

Gas leakage detector for R410A

Utility knife

Reamer

3

Speci

fi

cations

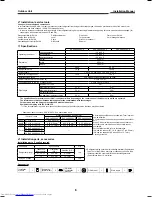

RAS-3M18S3AV-E

RAS-2M18S3AV-E

RAS-2M14S3AV-E

Operating conditions

*1

Cooling operation

–10 to 46 °C

Dry operation

–10 to 46 °C

Heating operation

–20 to 24 °C

Dimension

Height

630 mm

Width

800 mm

Depth

300 mm

Net weight

46 kg

44 kg

Refrigerant R410A

1.5 kg

1.32 kg

Power supply

1 ph, 50 Hz, 220-240 V 1 ph, 60 Hz, 220 V

Maximum running current

13.1 A

12.6 A

Installation fuse rating

20 A breaker or fuse (all types can be used)

Power cord (H07RN-F or 60245IEC66)

3-core 1.5 mm

2

Connecting cable (H07RN-F or 60245IEC66)

4-core 1.0 mm

2

or more

Pipe length

Minimum for 1 unit

2 m

Maximum for 1 unit

25 m

20 m

Maximum for total unit

50 m

30 m

Height difference

10 m

No additional refrigerant charge

50 m

30 m

The specifications for performance of this air conditioner differs depending on the combination of the indoor units which are operated.

The information in this specifications table applies for the combinations with the catalogue.

For operation, read the owner’s manual packed with the indoor unit.

Equipment complying with IEC 61000-3-12.

*1 If the air conditioner is used in conditions other than the above, the safety protection functions may be activated.

* Example of indoor unit class: RAS-B10UFV-E1 is abbreviated as “10”.

Indoor unit class

Standard connecting pipe diameter

RAS-3M18S3AV-E

RAS-2M18S3AV-E

RAS-2M14S3AV-E

Unit C

07 or 10 or 13

6.35, 9.52 mm

—

—

Unit B

07 or 10 or 13 or 16

6.35, 9.52 mm

*3

6.35, 9.52 mm

*3

6.35, 9.52 mm

Unit A

07 or 10 or 13 or 16

6.35, 12.7 mm

*2

6.35, 9.52 mm

*3

6.35, 9.52 mm

Total

36 (RAS-3M18S3AV-E)

—

32 (RAS-2M18S3AV-E)

26 (RAS-2M14S3AV-E)

All combinations that do not exceed the “Total” number

can be installed.

2 or more indoor units must be connected to an outdoor

unit.

When 2 indoor units are connected to an outdoor unit,

note that some combinations of indoor units are not

compatible.

For the further details, refer to the catalogue.

*2 Need the reducer (07, 10, 13 class 12.7 to 9.52 mm).

*3 Need the expander (16 class 9.52 to 12.7 mm).

• Locally procured.

4

Installation parts, accessories

Installation parts *Locally procured

Parts name

Specifications

Q’ty

*4 Refrigerant piping covered with insulating material (Polyethylene

foam, 6 mm thick) When duct-type or cassette-type unit is to be

installed, it shall be covered with thicker insulating material

(Polyethylene foam, 10 mm thick)

Refrigerant piping

*4

Indoor unit

(abbreviation)

Liquid side

(O.D.)

Gas side (O.D.)

1 ea.

07, 10, 13

6.35 mm

9.52 mm

16

6.35 mm

12.7 mm

Putty, PVC tapes

—

1 ea.

Accessories

Installation

manual

1

Rubber cap

(Water-proof)

2

CD-ROM

(Installation

manual)

1

F-GAS label

1

Drain nipple

1

1116691099_(01) EN.indd 6

1116691099_(01) EN.indd 6

9/22/15 5:59 PM

9/22/15 5:59 PM