– 15 –

◆

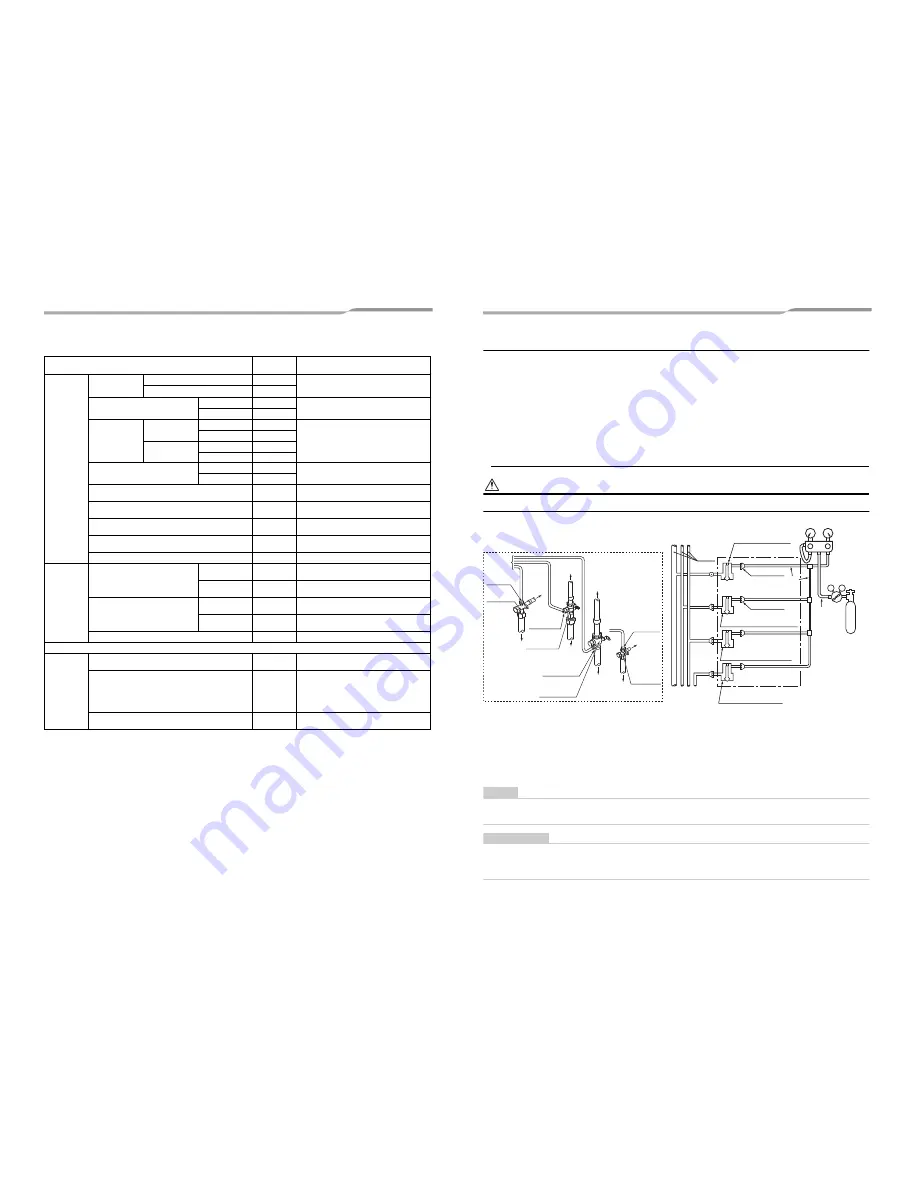

Allowable length and allowable height difference of refrigerant piping

*1: Farthest outdoor unit from the first branch: (C), farthest indoor unit: (o)

*2: Run wires to one indoor unit and flow selector unit linked with one of those remote controllers if flow selector unit is connected to multiple

indoor units.

*3: Allowable values for length equivalent to furthest pipe are shown below and they vary according to performance rank of outdoor unit.

22.4 to 40.0: 185 m, 45.0 to 78.5: 195 m, 85.0 to 118.0: 200 m

*4: When system capacity is greater than 28 HP, height difference between indoor units is limited to 3 m. If the piping exceeds 3 m with a

capacity greater than 28 HP there may be a case of capacity shortage in cooling.

*5: Ensure that the header unit is installed below all connected follower outdoor unit(s).

Possible product failure may occur if header unit is installed above any follower unit(s).

Item

Allowable

value

Pipes

Pipe length

Total extension of

pipe (liquid pipe,

real length)

Less than 34 HP or less

300 m

LA + La + Lb + Lc + L1 + L2 + L3 + L4 + L5 + L6

+ L7 + L8 + a + b + c + d + e + f + g + h + i + j +

k + l + m + n + o

34 HP or more

500 m

Farthest piping length L (*1, *3)

Equivalent length

200 m

LA + Lc + L1 + L3 + L4 + L5 + L6 + L7 + o

Real length

180 m

Max. equivalent

length of Main

piping

H2 > 3 m

Equivalent length

100 m

L1

Real length

85 m

H2

≤

3 m

Equivalent length

120 m

Real length

100 m

Farthest equivalent piping length from

the first branch Li (*1)

H2 > 3 m

50 m

L3 + L4 + L5 + L6 + L7 + o

H2

≤

3 m

65 m

Farthest equivalent piping length between outdoor units L0

(*1)

15 m

LA + Lc (LA + Lb)

Maximum equivalent piping length of pipes connected to

outdoor units

10 m

Lc (La, Lb)

Maximum real length of terminal branching section to

indoor units

30 m

a + f, b + g, c + h, d + l, e + j, k, l

Maximum real length of between Flow Selector unit and

indoor unit

15 m

f, g, h, l, j

Maximum equivalent length between branching sections

50 m

L2, L3, L4, L8

Height

difference

Height between outdoor and indoor

units H1

Upper outdoor

units

50 m

–

Lower outdoor

units

30 m

–

Height between indoor units H2

Upper outdoor

units

40 m

–

Lower outdoor

units (*4)

15 m

–

Height between outdoor units H3 (*5)

5 m

–

<In case of connecting flow selector unit to multiple indoor units>

Maximum equivalent length indoor units in group control by

one Flow Selector unit Ln

30 m

L5 + L6 + L7 + o

Maximum real length between Flow Selector unit and

indoor unit (*2)

15 m

To run wires to indoor unit (m):

L6 + m

≤

15 m, L5 + L6 + L7 + n

≤

30 m,

L5 + L6 + L7 + o

≤

30 m

To run wires to indoor unit (n):

L5 + L6 + m

≤

30 m, L6 + L7 + n

≤

15 m,

L5 + L6 + L7 + o

≤

30 m

Height difference between indoor units in group control by

one Flow Selector unit H4

0.5 m

–

Airtightness test

After the refrigerant piping has been finished, execute an airtight test.

For an airtight test, connect a nitrogen gas canister as shown in the figure below and apply pressure.

• Be sure to apply pressure from the service ports of the packed valves (or ball valves) at the liquid side, discharge

gas side, suction gas side and balance pipe side.

• An airtight test can only be performed at the service ports at the liquid side, gas side and balance pipe side on

header unit.

• Close the valves fully at the gas side, liquid side and balance pipe side. As there is a possibility that the nitrogen

gas will enter into the cycle of outdoor units, re-tighten the valve rods at the liquid side and balance pipe side

before applying pressure.

• For each refrigerant line, apply pressure gradually in steps at the liquid side, discharge gas side, suction gas side

and balance pipe side.

Be sure to apply pressure at the discharge gas side, suction gas side, liquid side, and balance pipe side.

WARNING

Never use oxygen, flammable gases, or noxious gases in an airtight test.

Able to detect a serious leakage

1. Apply pressure 0.3 MPa (3.0 kg/cm²G) for 5 minutes or more.

2. Apply pressure 1.5 MPa (15 kg/cm²G) for 5 minutes or more.

Available to detect slow leakage

3. Apply pressure 3.73 MPa (38 kg/cm²G) for approx. 24 hours.

• If there is no pressure decrease after 24 hours, the test is passed.

NOTE

However, if the environmental temperature changes from the moment of applying pressure to 24 hours after that, the pressure

will change by about 0.01 MPa (0.1 kg/cm²G) per 1 °C. Consider the pressure change when checking the test result.

REQUIREMENT

When pressure decrease is detected in steps 1-3, check the leakage at the connecting points.

Check the leakage using a foaming agent or other measures and seal the leak with re-brazing, flare retightening or other

methods. After sealing, execute an airtight test again.

V

L

V

H

Connected to

indoor unit

Main

piping

Suction gas side

valve fully closed

Low pressure gauge High pressure gauge

Brazed

Header outdoor unit

Fully

closed

Fully

closed

Connected to

other follower units

Balanced pipe side

valve fully closed

Liquid side valve fully closed

Service port

Ø6.4 copper pipe

Ø6.4

copper

pipe

Nitrogen

gas

Reducing

valve

Gauge

manifold

To gauge

manifold

Liquid-side

service port

Packed valve

of balance

pipe side

Service port of

discharge gas side

Piping at

site

Ball valve of

suction gas side

Service port of

suction gas side

Piping

at site

To outdoor unit

To

outdoor

unit

Liquid-side

valve

Packed valve

details

To outdoor

unit

Service port

of balance

pipe side

Fully

closed

Discharge gas side valve fully closed

Service port

To

gauge

manifold

To

outdoor

unit

Ball valve of

discharge gas side

Piping

at site

Piping

at site

29-EN

30-EN

Summary of Contents for MMY-MAP0804FT8-E

Page 37: ...EH99889397 ...