Ventilating fan control from wired remote controller

[Function]

• The start/stop operation can be operated from the wired remote controller when air to air heat exchanger

or ventilating fan is installed in the system.

• The fan can be operated even if the indoor unit is not operating.

• Use a fan which can receive the no-voltage A contact as an outside input signal.

• In a group control, the units are collectively operated and they can not be individually operated.

1. Operation

Handle a wired remote controller in the following procedure.

∗

Use the wired remote controller during stop of the system.

∗

Be sure to set up the wired remote controller to the header unit. (Same in group control)

∗

In a group control, if the wired remote controller is set up to the header unit, both header and follower

units are simultaneously operable.

1

Push concurrently

SET

+

CL

+

TEST

buttons for 4 seconds or more.

The unit No. displayed firstly indicates the header indoor unit address in the group control.

In this time, the fan of the selected indoor unit turns on.

2

Every pushing

UNIT LOUVER

button (button at left side), the indoor unit numbers in group control are

displayed successively.

In this time, the fan of the selected indoor unit only turns on.

3

Using the setup temp

or

button, specify the CODE No

31

31

31

31

31

.

4

Using the timer time

or

button, select the setup data. (At shipment:

0000

0000

0000

0000

0000

)

The setup data are as follows:

Setup data

0000

0001

Handling of operation of air to air heat exchanger or ventilating fan

Unavailable (At shipment)

Available

5

Push

SET

button. (OK if display goes on.)

• To change the selected indoor unit, go to the procedure

2

).

• To change the item to be set up, go to the procedure

3

).

6

Pushing

TEST

returns the status to the usual stop status.

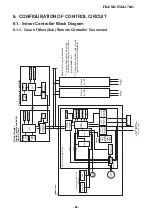

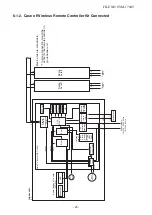

2. Wiring

1

2

1

2

CN32

FAN DRIVE

(2P WHI)

Outside control

input of fan

To terminal

Relay (DC12V, procured locally)

Corresponds to the relay up

to one that the rated current

of the operation coil is approx. 75mA

Indoor control

P.C. board

Note)

Determine the cable length between the

indoor control P.C. board and the relay within 2m.

Compact 4-way Air Discharge Cassette type

4-way Air Discharge Cassette type

2-way Air Discharge Cassette type

1-way Air Discharge Cassette type (2 series)

Concealed Duct Standard type

Slim Duct type

Under Ceiling type

High Wall type

Corresponds up to a relay in which rated current of

the operation coil is approx. 75mA

Other type models:

Correspond up to a relay in which rated current of the

operation coil is approx. 16mA (Does not correspond to a

terminal block type relay on the market.)

⎫

⎬

⎭

model :

FILE NO. SVM-17045

- 35 -