Basic Installation and Operation Guide

JK 400 Series Fixed Controllers

TOSHIBA

2

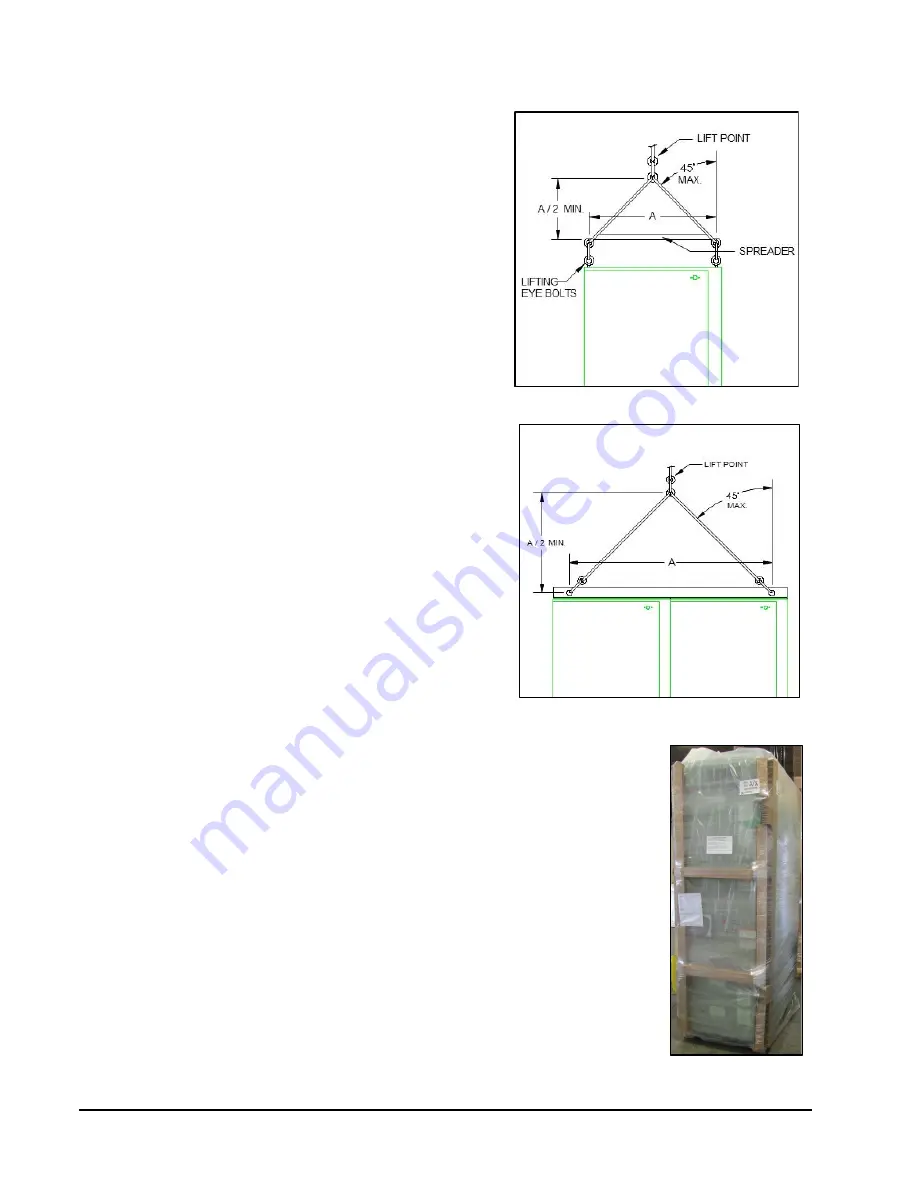

Overhead Lifting

When it is necessary to move the equipment between

elevations, overhead hoisting may be required. Lifting angles

(for multiple controller sections) are provided on top of the

enclosure for this purpose. Spreaders (Fig.

2) should be used to

provide the vertical lift on single controllers to prevent eye-bolt

failure. Always keep the controller upright while lifting. Some

controller sections may contain heavy or special equipment that

will cause the center of gravity to be off-center. Rigging lengths

should be adjusted to maintain the controller in an upright

position. The angle between the lifting cables and vertical should

not be allowed to exceed 45 degrees (Fig.

3). Ropes or cables

should not pass through the holes in lifting angles or eye-bolts.

Slings with safety hooks or shackles of adequate load rating

should be used.

Fig. 2 Use of Spreader Bar - Single Section

Initial Inspection

•

Make a complete visual check of the unit for damage which

may have occurred during shipping and handling. Do not

attempt to continue installation or start up the unit if it is

damaged.

•

Check for loose mechanical assemblies or broken wires

which may have occurred during transportation or handling.

Loose electrical connections will increase resistance and

cause the unit to function improperly.

•

Prior to beginning the installation, verify that the load and

JK unit are rated for the proper amperage and voltage.

Fig. 3 Lifting Multiple Sections

LOCATION

Storage

If the controller is to be stored for any length of time prior to installation, the packing

should be restored for protection during that period. Where conditions permit, the

packing should be left intact until the controller is at the final installation position. If the

packing

(Fig. 4)

is removed, the top and openings of the controller should be covered

during the construction period to protect it against dust and debris.

Indoor Equipment

Controllers designed for indoor installation (e.g. Type 1, 12) that are not to be installed

and energized immediately should be stored in a clean, dry space where a uniform

temperature prevents condensation. Preferably, the controller should be stored in a

heated building, with adequate air circulation and protected from dirt and water.

Equipment should be stored where it is not subject to mechanical damage, especially

Fig. 4 Storage