5. SYSTEM MODE

EM18-33031

5.5 SET PARAMETERS

5-38

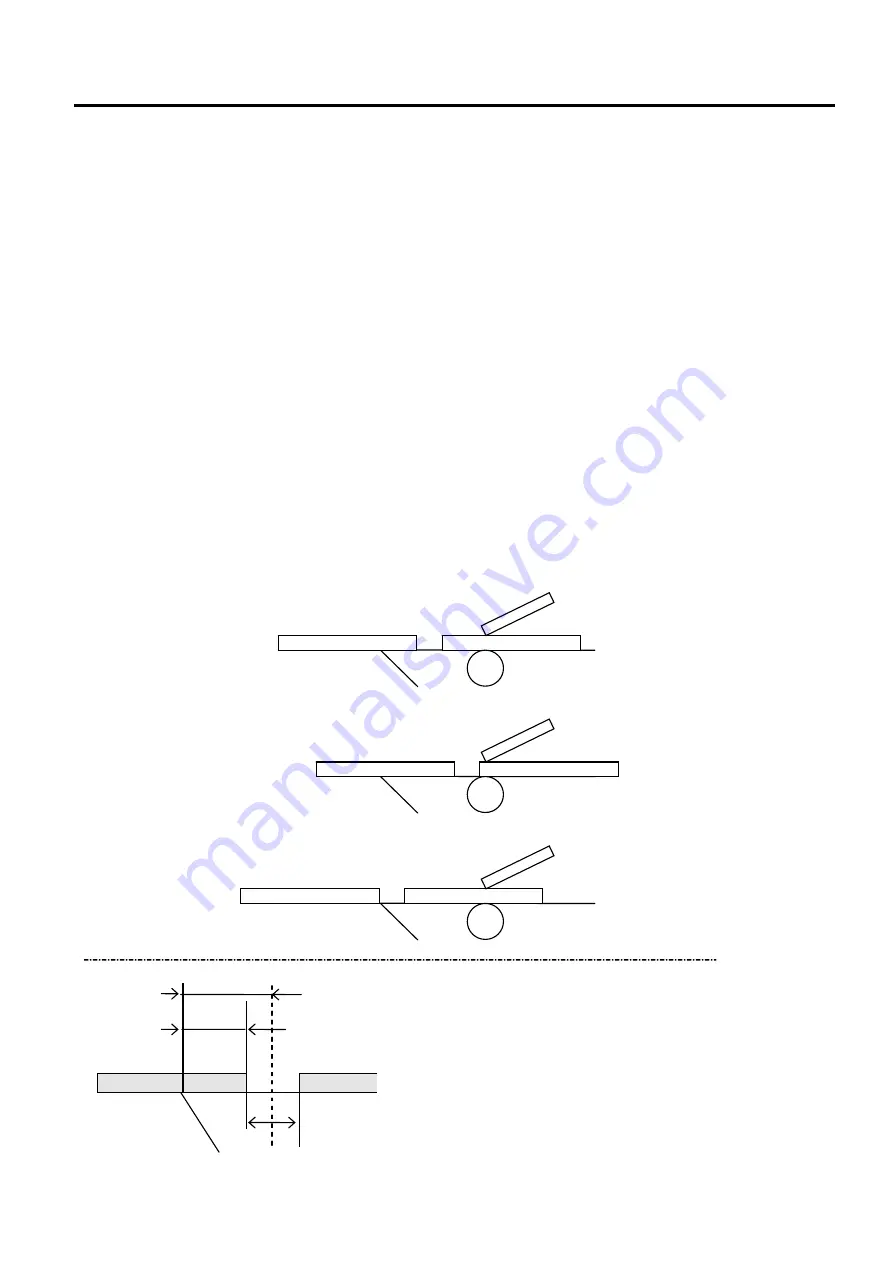

3. Procedure for label having less than the min. label pitch for each issue speed when the rotary cutter

is

used

When the following conditions are all met, the cut operation for the last label to be cut is performed as

follows.

Forward feed to the cut position

Cut while feeding

Feed stops

Head lifted

Reverse feed to the home position

Head lowered

Conditions: Issue Command, Feed Command, and Eject Command received.

Label pitch: Less than the min. label pitch for each issue speed,

cut performed, transmissive sensor designated, cut position fine adjustment of

±10.0 mm or less, and issue mode “C”

* For the Issue Command, this procedure is effective only when the next Issue Command is

not received at the last label to be cut.

* The print head can be lifted/lowered only when the optional ribbon saving module is

mounted and the ribbon saving function is set to ON with the parameter setting menu.

When the ribbon saving module is not installed, the print head is not lifted or lowered.

*

If the bottom edge of the last label advances past the feed roller while the print head is

lifted during label feed to cut, the sensor may not be able to detect an error even if the

label cannot be fed any more.

*

If the head-up solenoid temperature is high, the print head may not be lifted.

4. Strip position fine adjustment

0.0mm

+3.0mm

-3.0mm

4mm

3mm

▼

2mm

Printing in strip issue mode is stopped at the position

where the distance from the middle point of the gap

between labels to the end of the strip shaft is 4 mm,

since the gap between labels is assumed to be 2 mm.

When the print stop position is not proper due to a

greater gap, the print stop position should be adjusted

using the strip position fine adjust function.