the retainer fork and disconnect this existing hose.

Retain the large fork at this location for later use.

2. Follow this hose until it terminates on the left side

of the valve manifold. This hose is connected to

the side of the valve manifold facing to the front of

the machine (Figure 55). Loosen the hose clamp

securing the hose and disconnect it from the barb

on the valve manifold. Discard this hose and retain

the hose clamp.

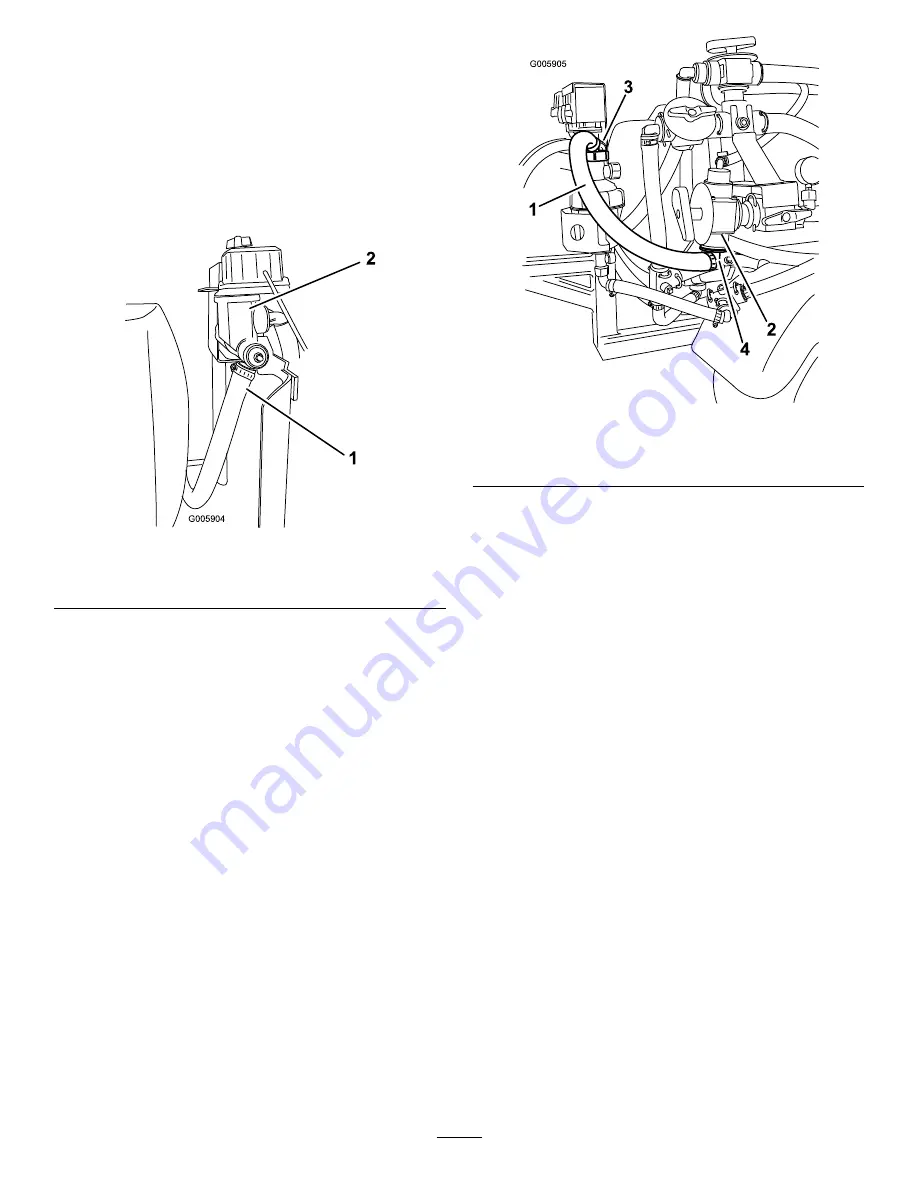

G005904

1

2

Figure 55

1.

Left side of valve manifold

2.

Boom supply hose,

terminating

3. Locate filter supply hose in loose parts (Figure 1). It

has a 70 degree fitting on one end and a 90 degree

fitting on the other end.

4. Install the 70 degree fitting on this hose to the

open port on the top of the pressure filter installed

previously. Use the plastic nut on the fitting to secure

the hose to the pressure filter (Figure 56).

G005905

1

2

3

4

Figure 56

1.

Filter supply hose

3.

70 degree fitting

2.

Rinse valve, vertical

4.

90 degree fitting

5. Route the remaining end to the vertically orientated

rinse valve on the control valve assembly. Install

the 90 degree fitting to the open port on the rinse

valve and use the existing large fork to secure the

connection (Figure 56).

6. Locate manifold supply hose in loose parts

(Figure 1). It has a 70 degree fitting on one end and

is open on the other end.

7. Install the 70 degree fitting on this hose to the

remaining, open port on the side of the pressure

filter facing toward the front of the machine. Use

the plastic nut on the fitting to secure the hose to

the pressure filter.

8. Route the open end from the pressure filter to the

left side of the machine between the main tank and

the valve manifold.

9. Slide the hose clamp removed previously over the

open end of the hose and install the open end onto

the open hose barb on the left side of the valve

manifold. Use the hose clamp to secure the hose to

the valve manifold.

Important:

Upon completion of securing the hose

fittings, check to see that all hose are not kinking

or are twisted. If a hose shows signs of torsion,

loosen the metal hose clamp securing the hose to

the fitting. Rotate the hose on the fitting until the

stress on the hose is relieved. Tighten the metal

hose clamp.

26