❏

3. Remove the engine. Drill 1/8" [3.2mm] holes at

the marks. Mount the engine to the mount with four

4-40 x 1" [25mm] SHCS (socket head cap screws),

#4 flat washers and lock washers and 4-40 blind nuts.

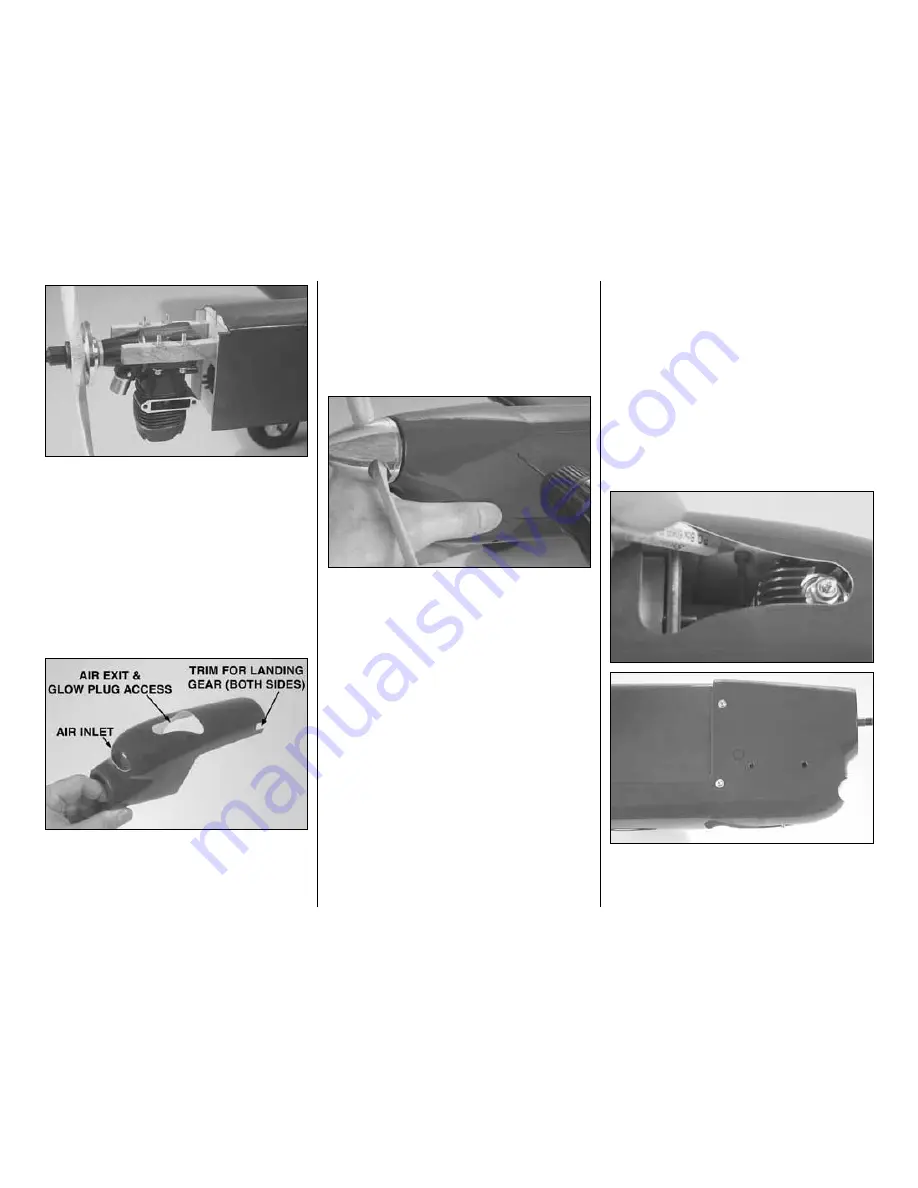

Mount the Cowl

❏

1. Use a high-speed rotary tool with a cutting bit to

cut slots in the aft end of the cowl to accommodate

the landing gear wires. Also cut an air inlet and air

exit hole. The exit hole may be combined with the

glow plug access hole.

❏

2. Place the cowl on the fuselage and mount the

spinner and propeller. Align the cowl with the spinner.

There should be approximately 3/32" [2mm] between

the spinner and the cowl.

❏

3. Holding the cowl in position, drill a 1/16" [1.6mm]

hole through the cowl and fuselage for one of the

cowl mounting screws. The hole should be about

5/16" [8mm] from the aft edge of the cowl, placing it

about 1/4" behind the front edge of the fuselage side.

Screw in a #2 x 1/4" [6mm] screw just enough to hold

the cowl, but do not tighten the screw.

❏

4. One at a time while holding the cowl in position,

drill a 1/16" [1.6mm] hole and insert a screw at the

remaining three marks. Also drill a hole through both

sides of the cowl and fuselage approximately 3/4"

[20mm] forward of the landing gear.

❏

5. Remove the cowl. Enlarge the holes in the cowl

only with a 3/32" [2.4mm] drill. Test fit the cowl and

mount it to the fuselage with six #2 x 1/4" [6mm] screws.

❏

6. Remove the cowl screws and cowl. Add a

couple of drops of thin CA to the screw holes–don’t

add too much CA, or you will seal the holes.

❏

7. Cut the holes in the cowl for the muffler screws.

This can be done by using a pencil to mark the

heads of the screws on the inside of the cowl, and

then removing the cowl and cutting the holes.

- 15 -