❏

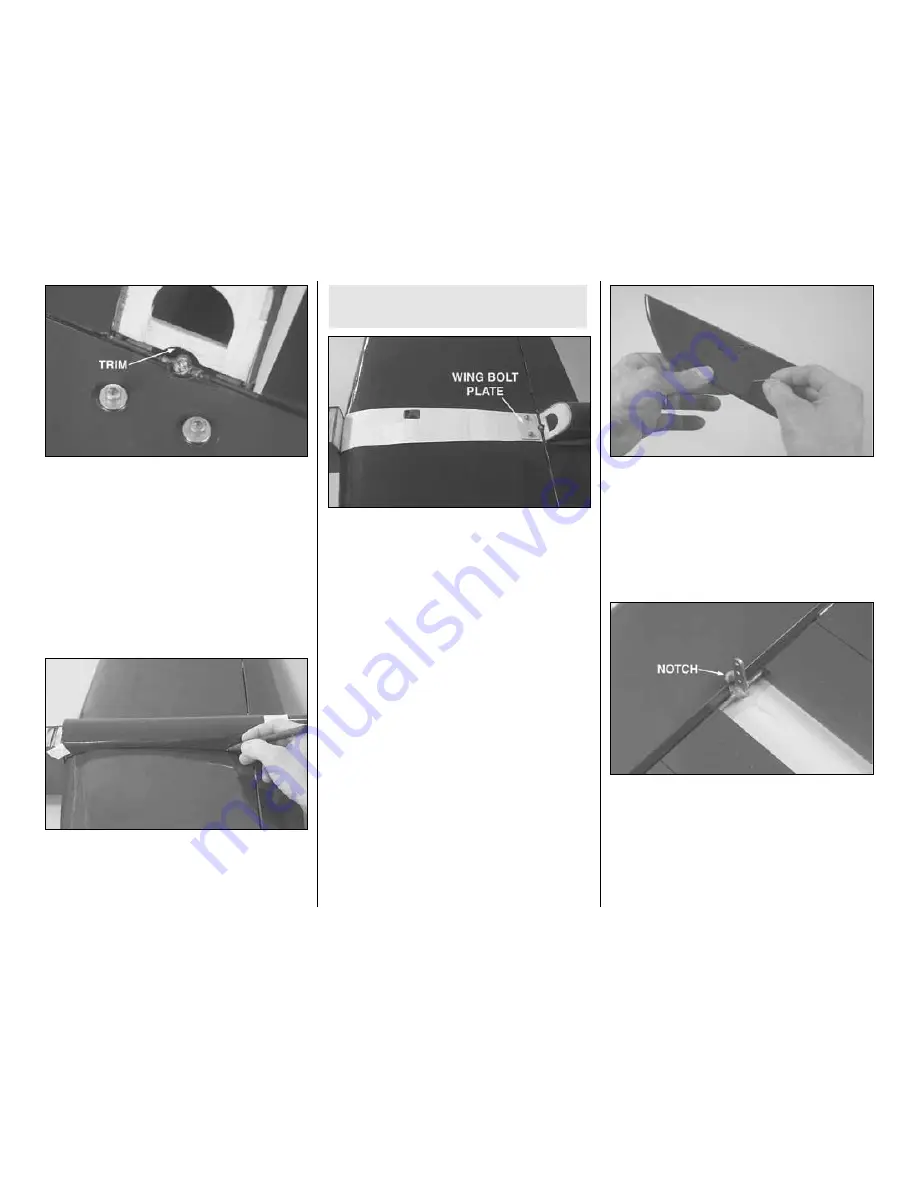

3. Remove the belly pan from the bottom of the

fuselage. Temporarily bolt the wing to the fuselage

with two 4-40 x 1-1/2" [38mm] screws and #4

washers. Trim the balsa cross brace as necessary

to accommodate the solder joint holding the control

horn to the flap joiner wire.

❏

4. Place the belly pan on the bottom of the wing in

alignment with the fuselage. Tape the belly pan into

position. Use a fine-point felt-tip pen to mark the

outline of the belly pan onto the bottom of the wing.

Mark the fuselage sides on the top of the wing.

❏

5. Remove the belly pan and wing. Use a sharp,

new knife blade or a heated soldering iron to cut the

covering from the wing 1/16" [2mm] inside the lines.

If using a knife, use a light touch and great care not

to cut into the sheeting under the covering or the

wing will be weakened. Using a soldering iron is

preferred because it melts through the covering

without cutting into the wood. Move the soldering iron

fast enough to melt through the covering without

burning the wood. After cutting the covering use

denatured alcohol and a tissue to clean the ink lines

from the covering. Then, peel off the covering.

❏

6. Center the 1" x 1-1/2" [26 x 38mm] plywood

wing bolt plate over the holes on the bottom of the

wing. Glue the plate into position. Using the holes in

the top of the wing as a guide, drill 9/64" [3.6mm] (or

1/8" [3.2mm]) holes through the plate. Bolt the wing

onto the fuselage.

ASSEMBLE THE FUSELAGE

Prepare the Stab

❏

1. Examine the stab and elevators and determine

which side looks best. Use a felt-tip pen to write “top”

on the side that looks best.

❏

2. Separate the elevators from the stab by peeling

off the tape. Use a pin to poke three or four holes

along one side of all the “ribs” in the bottom of the

stab and elevators. These holes will allow expanded

air to escape while tightening the covering.

❏

3. Use a covering iron to tighten the covering on

the stab and elevators.

❏

4. The same as was done with the wing and flaps,

prepare the elevators and stab for the hinges by

enlarging the slots if necessary, test fitting the hinges

and cutting “V” notches in the elevators to

accommodate the hinge pins. Also prepare the

elevators for the joiner wire. Trim the trailing edge of

the stab as necessary to accommodate the solder

joint on the joiner wire. “Tweak” the joiner wire as

necessary to align the elevators with each other.

Refer to this photo for the following

two steps.

- 10 -