WWW.TMGINDUSTRIAL.COM

18 / 27

dŽůů&ƌĞĞ

:1-887-761-2819

M A I N T E N A N C E

MAINTENANCE

By following a careful service and maintenance program for your machine, you will enjoy many years of

trouble-free operation.

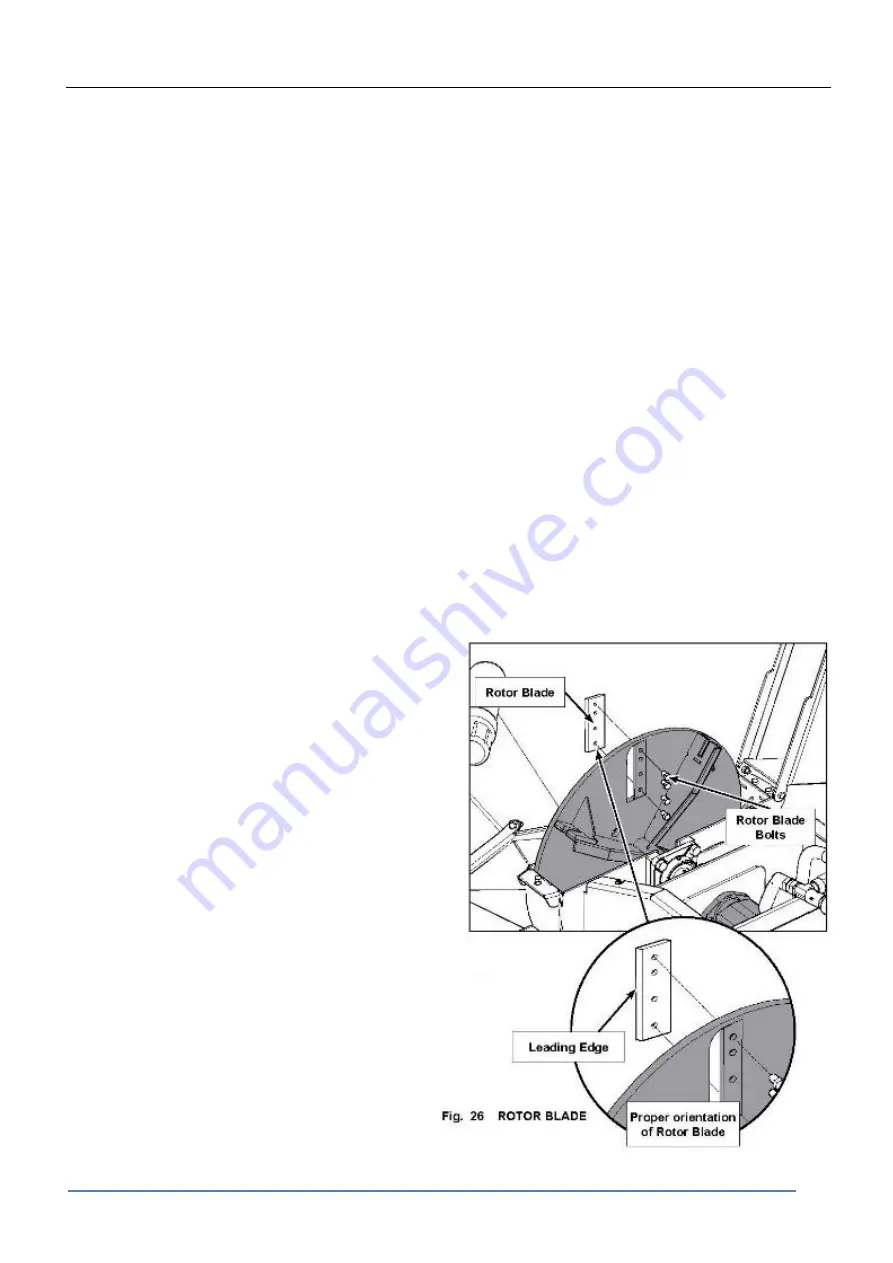

Blade and Breaker Maintenance

The rotor and ledger blades need to be sharp for the Chipper to perform as expected. Periodic inspection is

recommended. Keep the blades sharp to reduce the amount of power required during operation. Watch the

sharpness of the blades when processing material with a lot of sand, soil or dirt mixed with it. Reverse or

sharpen the blades if the cutting edge becomes dull. Twig breaker should be inspected for gouges or bent.

Rotor Blades:

The rotor is equipped with 4 blades spaced evenly to keep the rotor in balance. If one needs to be changed,

the one opposite should also be changed.

It is recommended that the rotor blades be removed from the rotor when sharpening. Always sharpen the

blades at a 45° angle to provide the best cutting effect as it meets the stationary blade. Be sure to tighten the

blade mounting bolts to their specified torque when reinstalling the blades to the rotor.

1.

Turn off the hydraulics, stop the engine,

remove the ignition key, and place it in your

pocket and wait for all moving parts to stop.

2.

Remove the bolt that secures the upper rotor

housing, and carefully open the rotor

housing.

3.

Manually rotate chipper rotor plate so that the

blade is fully exposed

4.

Remove the bolts that hold the rotor blade to

the rotor, remove the blade.

5.

Rotate the blade and reinstall or replace with

new or resharpened blade.