12

■

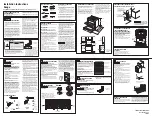

VENTILATION

9-1/8"

11-1/2

"

15"

7"

3-3/8

"

10-3/4"

9-1/8"

11-1/2"

A

Front

A

B

B

Rear Wall

Figure 20 – Floor Venting

CL

* See Step 8

*

*

1.

Floor ducting with an integral blower requires ducting

to the left within the area shown in Figure 20. Floor

joists may be avoided by rotating the blower and using

Elbow Model #STL90R, (purchased separately). See Table

1, Page 17.

2.

Secure the rear mounting rod in position "A". The

rear mounting rod has preset nuts on each end. Tighten

nut against plenum.

3.

Secure the front mounting rod in position "A". The

front mounting rod has one preset nut which shall be

tightened against plenum.

4.

Place blower inlet over plenum outlet ring (Figure

14), temporarily supporting blower with wood blocks.

5.

Place slot end of blower mounting bracket over

rear mounting rod lower nut.

6.

Rotate blower mounting bracket under blower for

support removing wood blocks as necessary.

7.

Place hole in blower mounting bracket over front

mounting rod and secure tightly with nut provided. Insure

gasket between blower and plenum is compressed.

8.

A short 90

°

Elbow Model STL90R (see page 17) is

available when integral blower exit hole through floor is

9-1/8" from centerline in Figure 20. A standard 6", 90

°

elbow shall be used when hole is more than 9-1/8"

from .

INTEGRAL BLOWER - FLOOR DUCTING

CL

Summary of Contents for RDDS30V

Page 16: ...16 BLOWER DUCT SIZING...