ECOCONDENS SILVER PLUS

ISU-646:2016/GR-H str.12

Low-temperature circuits

In the low-temperature area, it is recommended to treat the water by using heat transfer fluid HP-5 or Fernox AF10 biocide.

Filtration technique

Additionally, in order to ensure the quality of operation heating system, it is recommended to mount a modern filters, which works on

the principle of the magnetic and cyclone effect, for example Fernox TF1 filter.

Notice:

- method and amount of use specific products for system cleaning and water treatment should be in accordance to the product

manufacturer's instruction.

- above steps should be made by the autorized installer or service technician.

3.6. Connection of the boiler to a domestic hot water system

It is recommended to install cut-off valves on a domestic hot water system what will enable easier maintenance and service.

It is recommended to install a water filter on the connection with the domestic water supply. This filter is not included

in the standard boiler equipment.

3.7. Condensate outlet

Condensate formed during the combustion process must be drained according the following conditions:

•

Installation of condensate drain must be made of corrosion-resistant material.

•

Connection of draining the condensate cannot be blocked.

•

To facilitate to drain the condensate through the flue gas all horizontal flue pipes must be installed with a fall of 3

o

(52mm / m).

3.8. Flue gas outlet

Condensate formed during the combustion process must be drained according the following conditions:

EcoCondens SILVER PLUS boilers could be installed as B-type appliances (where air needed for combustion is taken from the room

where boiler is installed) or as C-type appliances (where air needed for combustion is taken from outside). C-type appliances could be

divided as follows:

Depending on local regulations some types of installations might not be allowed. Always consult your local regulations before making

flue-gas system project.

Before turning on the boiler check if flue-gas system is made according to the project and air- and flue ducts lengths are shorter than

maximum lengths showed in tables 3.8... Make sure flue-gas system is tight.

After turning on the boiler check if it operates correctly. Also check combustion parameters by checking concentration of CO

2

and/or

O

2

in flue-gas.

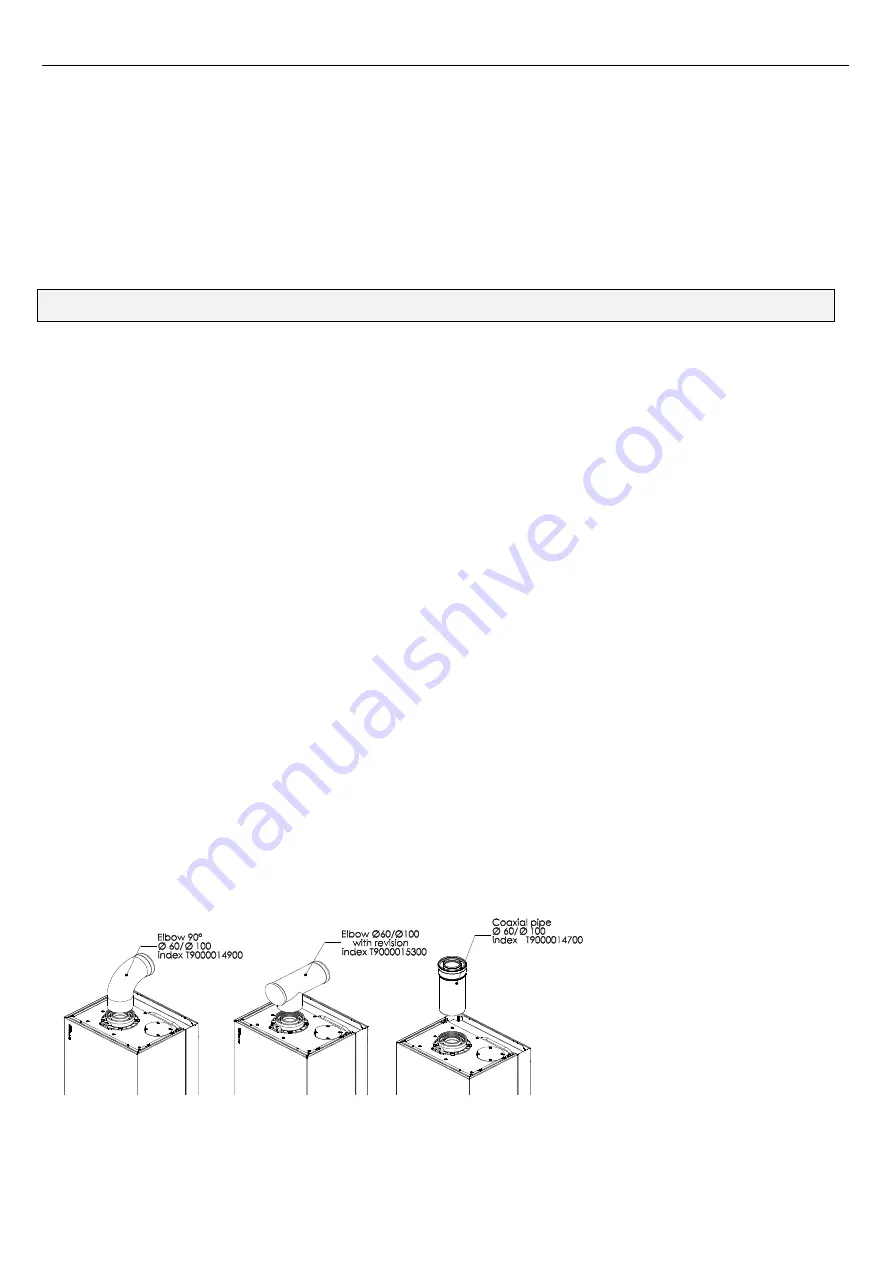

Ways of connecting the boiler to the air-flue gas system

Fig. 3.8...

To ensure proper functioning of the device use the appropriate wire size (diameter, maximum length, resistance on the knees),

depending on the combustion system used. The dimensions of the wires should be adequately compatible as given in table.

Resistance of flue gas flow on each elbow depending on the bending angle and related reduction of the maximum wire length are given

in section 3.8.6.

Each system should be installed with the windproof outlet protecting against external factors.

For condensing boilers ECOCONDENS SILVER PLUS there are provided three types of flue gas-air systems: coaxial system

∅

80/

∅

125 and

∅

60/

∅

100 and 2 separate 2 x

∅

80. It is possible to apply air-flue gas pipe made from polypropylene or stainless steel.

The individual components of flue gas- air systems are given in table 7.1

NOTICE:

The boiler is factory adjusted for the coaxial exhaust system Ø60/100 of the maximum pipe length 3m + elbow. Settings O2 – 5%. To

use the other systems and longer pipes it is required to adjust the boiler as specified in point 4.2.

Coaxial reduction

∅

60/

∅

100 x

∅

80/

∅

125 shall be applied when using coaxial air-flue gas pipe

∅

80/

∅

125. Inspection T-piece shall be

applied when using air-flue gas pipe made from stainless steel.

Condensing boilers SILVER PLUS meet the requirements to use in multi-storey air-flue gas systems LAS.

3.8.1. The ways of mounting adapters (elbows connection) to the boiler type

Coaxial system (air-flue gas pipe made from polypropylene)

Summary of Contents for ECOCONDENS SILVER PLUS-20

Page 31: ......