Drive Sprocket Rollers

ASV rubber track loaders utilize rollers on the drive

sprockets to drive the track. These rollers help mini-

mize friction between the track and the drive sprocket

to prolong track life.

The rollers rotate around hardened steel pins and usu-

ally wear on their inside surfaces. As they wear, the

rollers become thinner, but will continue to function as

long as they rotate freely around the pins. Sprocket

rollers should be inspected every 50 hours of operation

and replaced if cracked or worn to less than 35% of

original thickness. (.088”)

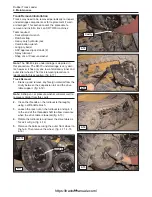

To replace worn rollers:

1.

Begin by performing steps 1-4 in the track removal

procedure on page 4-6 to allow the sprocket to be

removed.

2.

Remove the seven bearing plate mounting bolts

(A, I), then remove the plate (B) from the drive

table.

3.

Remove the bearing cap (G) by tapping around the

bulged area of the cap with a hammer. This will

relieve the outward pressure on the cap and allow

for removal.

4.

Remove the external snap ring (H) from the bear

ing shaft.

5.

Using a puller, remove the bearing assembly (J)

from the shaft.

6.

Remove the sprocket mounting bolts (C), then

remove the sprocket.

Note:

You may need to pry or lift the track upwards

with a hoist above the drive sprocket to provide clear-

ance for removal.

7.

Remove one bolt (F) holding the steel pins (D) and

rollers (E) in place. Install the new rollers over

the pins, then slide the bolt back through the

sprocket and pins and secure it with the nut (K).

8.

Repeat this process as required throughout the

sprocket.

9.

Reinstall the sprocket by reversing steps 2-6.

Note:

During removal of the bearing cap (step 3) the

bulged area of the cap is beaten inward. When rein-

stalling, orient the cap so that the domed area is facing

outward. Then tap the center of the cap with a ball

peen hammer or similar device to reset the cap. Do

this gently. Too much inward force can damage (mush-

room) the bearing shaft.

10.

Repeat steps 1-9 on the other side of the machine

if necessary.

11.

Perform the track tension adjustment and check

procedures on page 4-4.

Note:

Replace rollers as a set to simplify inspection

and maintain proper sprocket function.

4-5

Rubber Track Loader

4. Maintenance

New Roller Normal Wear

35% life

Steel Pin

(.088”)

A

H

F

E

D

C

SR-70

D

E

F

SR-80

J

I

G

B

K

4-10

https://tractormanualz.com/

Summary of Contents for ASV SR70

Page 5: ...IV https tractormanualz com...

Page 11: ...1 6 https tractormanualz com...

Page 41: ...4 20 https tractormanualz com...

Page 87: ...12 8 https tractormanualz com...

Page 105: ...14 6 https tractormanualz com...

Page 109: ...15 4 https tractormanualz com...

Page 125: ...16 16 https tractormanualz com...

Page 133: ...17 8 https tractormanualz com...

Page 137: ...18 4 https tractormanualz com...

Page 139: ...19 2 https tractormanualz com...