13

Temposonics

®

GB-Series SSI

Operation Manual

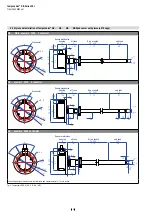

agnet mounting ith magnetic material

hen using magnetic material the dimensions of Fig. 15 must

be observed.

A.

If the position magnet aligns with the drilled piston rod

B.

If the position magnet is set further into the drilled piston rod,

LQVWDOODQRWKHUQRQPDJQHWLFVSDFHUHJSDUWQRDERYH

the magnet.

6HQVRUVZLWKVWURNHOHQJWKVŰPHWHUIW

6XSSRUWKRUL]RQWDOO\LQVWDOOHGVHQVRUVZLWKDVWURNHOHQJWKIURPPHWHU

mechanically at the rod end. ithout the use of a support, rod and posi -

tion magnet may be damaged. A false measurement result is also possi-

ble. onger rods require evenly distributed mechanical support over the

HQWLUHOHQJWKHJSDUWQR8VHDQ8PDJQHW)LJIRU

measurement.

Fig. 16:

([DPSOHRIVHQVRUVXSSRUW

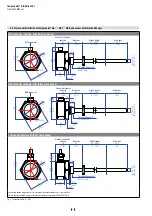

cti e measuring range

The technical data of each sensor is checked as well as documented

DQGWKHDFWLYHVWURNHOHQJWKXVHIXOHOHFWULFDOVWURNHZLWKLWVVWDUWDQG

HQGSRVLWLRQLVDGMXVWHGGXULQJğQDOLQVSHFWLRQDQGWHVWLQJ)LJ

To ensure that the entire measuring range can be used electrically, the

SRVLWLRQPDJQHWPXVWEHPRXQWHGPHFKDQLFDOO\DVIROORZV

*%6HULHVZLWKSUHVVXUHğWĠDQJHZLWKULQJ8PDJQHW

40

Stroke length

63.5

Reference edge of mounting

Start position

*%6HULHVZLWKWKUHDGHGĠDQJHZLWKULQJ8PDJQHW

40

Stroke length

63.5

Reference edge of mounting

Start position

)LJ$FWLYHPHDVXULQJUDQJH

NOTICE

On all sensors, the areas left and right of the active stroke length

DUHSURYLGHGIRUQXOODQGGHDG]RQH7KHVH]RQHVVKRXOGQRWEH

used for measurement, however the active stroke length

can be exceeded.

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

Fig. 15:

,QVWDOODWLRQZLWKPDJQHWLFPDWHULDO

Magnet

Magnet

1

2

3

3

A

B

Magnetic

material

1XOO]RQHGHSHQGVRQVHQVRUPRGHOVHH)LJ

2

Distance between position magnet and any magnetic material

ŰPPŰLQ

3

1RQPDJQHWLFVSDFHUŰPPŰLQŋ

5HFRPPHQGDWLRQPPLQ

U-magnet

Sensor rod

Non-magnetic fixing clip