12

Temposonics

®

GB-Series SSI

Operation Manual

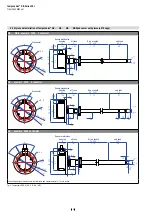

Fig. 12:

1RWLFHIRUWKUHDGHGĠDQJH0ūJEDVHGRQ',1,62

1RWHWKHIDVWHQLQJWRUTXHRI1P

6HDWWKHĠDQJHFRQWDFWVXUIDFHFRPSOHWHO\RQWKHF\OLQGHUPRXQWLQJ

surface.

The cylinder manufacturer determines the pressure-resistant

JDVNHWFRSSHUJDVNHW2ULQJHWF

The position magnet should not grind on the sensor rod.

7KHSLVWRQURGGULOOLQJŰPPŰLQGHSHQGVRQWKH

pressure and piston speed.

Adhere to the information relating to operating pressure.

Protect the sensor rod against wear.

1RWLFHIRUPHWULFWKUHDGHGĠDQJH

4.4 agnet instal lation

Typical use of magnets

agnet

%HQHğWV

Ring magnets

5RWDWLRQDOO\V\PPHWULFDOPDJQHWLFğHOG

-magnets

eight tolerances can be compensated

ounting ring magnets and -magnets

Install the magnet using non-magnetic material for mounting

device, screws, spacers etc.. The magnet must not grind on

the sensor rod. Alignment errors are compensated via the air gap.

3HUPLVVLEOHVXUIDFHSUHVVXUH0D[1PP

2

)DVWHQLQJWRUTXHIRU0VFUHZV1PXVHZDVKHULIQHFHVVDU\

Minimum distance between position magnet and any magnetic

PDWHULDOKDVWREHPPLQ)LJ

If no other option exists and magnetic material is used, observe the

VSHFLğHGGLPHQVLRQV)LJ

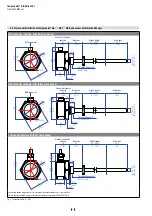

Fig. 13:

7\SLFDOXVHRIULQJPDJQHWVDQG8PDJQHWV

NOTICE

Mount ring magnets and U-magnets concentrically.

Do not exceed the maximum acceptable gap.

Fig. 14:

0RXQWLQJRI8PDJQHWSDUWQR

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUVDQGPHDVXUHPHQWVLQDUHLQLQFKHV

Thread

d

d

2

d

3

d

4

d

5

.

.4

2

3

4

GB-

0ūJ Ű

Ű

24.5

2.4

2

26

Ź

Ød

5

Ra 3.2

Ra 3.2

Pitch diameter

A

A

Thread

(d

1

× P)

Ød

3

(Reference)

A

Ød

2

Ød

4

(Gauging)

This dimension applies when

tap drill cannot pass through

entire boss.

≤ R0.4

R0.3

R0.1

Z°

45

°

±

5

°

L

3

L

1

L

2

L

4

A

0.1

A

0.2

&RQWUROOLQJGHVLJQGLPHQVLRQVDUHLQPLOOLPHWHUV

M4

1

2

Air gap

Concentric mounting

of U-magnet

Part no. 201 553:

3 ±1 (0.12 ±0.04)

Part no. 251 416-2:

1.75 ±1 (0.07 ±0.04)

U-magnet

Non-magnetic mounting plate and fasteners

1

2