Page 3-65

Chapter 11: Troubleshooting

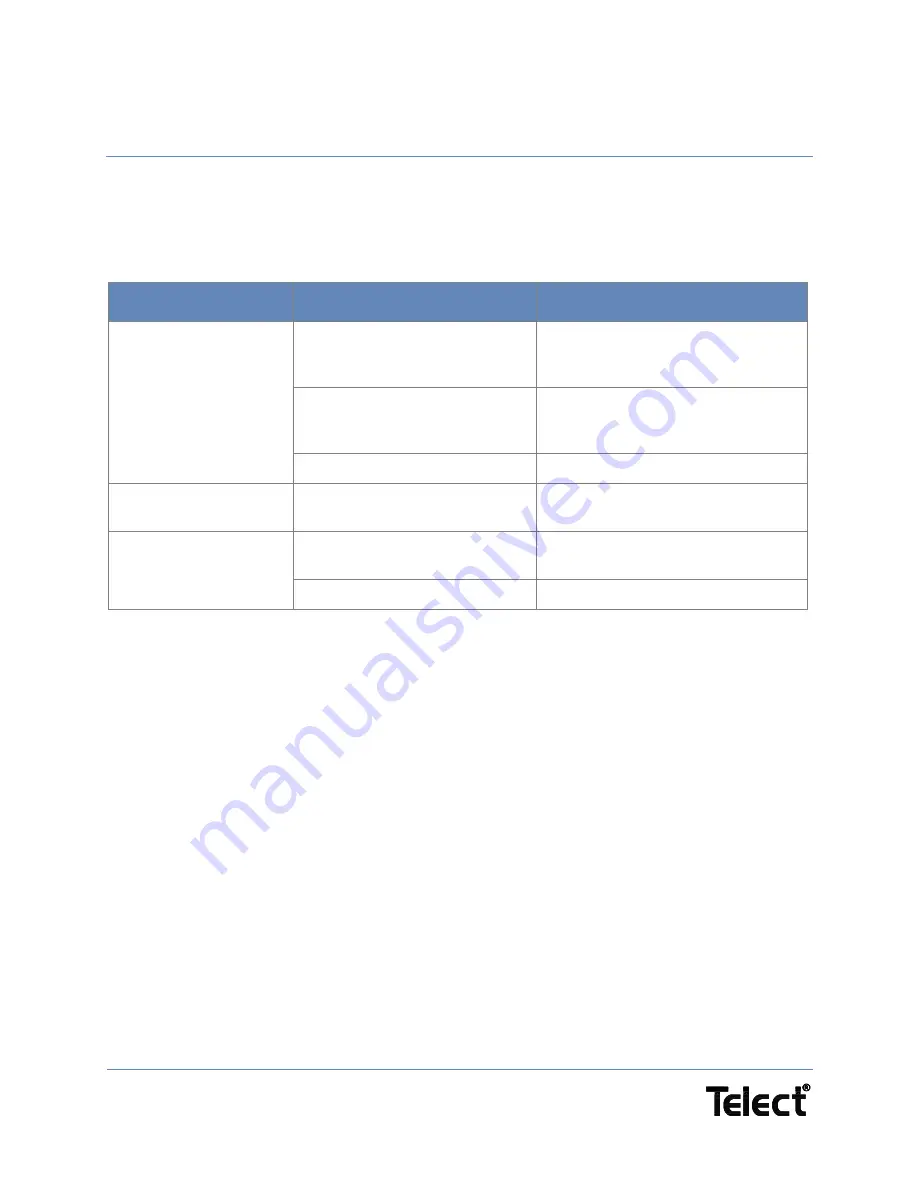

4.1 Fan/air Flow Issues

The following symptoms can occur with the fan or cooling system.

Table 3 - Fan/air flow issues and solutions

Symptom

Probable cause

Solution

No air flow into enclosure

No power to fan or fan controller

Check power distribution panel output

to both fan and fan controller for +27V

and ground.

Faulty fan(s). Seized bearings

or no tachometer output to

fan controller

Replace fan(s).

Faulty fan controller

Replace fan controller board.

Reduced air flow

into enclosure

Dirty filter

Replace or clean air filter.

Noisy fan

Fan not properly aligned

Loosen mounting screws and adjust

alignment.

Faulty fan or worn fan bearings

Replace fan(s).