Performance Verification Procedures

4- 6

TLA721 Benchtop & TLA7XM Expansion Mainframe Service Manual

There are no certifiable parameters for the TLA7XM Expansion Mainframe.

Performance Verification Procedures

This section contains procedures to verify that the TLA721 Benchtop Mainframe

and the TLA7XM Expansion Mainframe perform as warranted. Verify instru-

ment performance whenever the accuracy or function of your instrument is in

question.

Do the following tests listed in Table 4--3 to verify the performance of the

TLA721 Benchtop Mainframe and the TLA7XM Expansion Mainframe. You

will need some of the equipment shown in Table 4--1 on page 4--3 to complete

the performance verification procedures. If you substitute equipment, always

choose instruments that meet or exceed the minimum requirements specified.

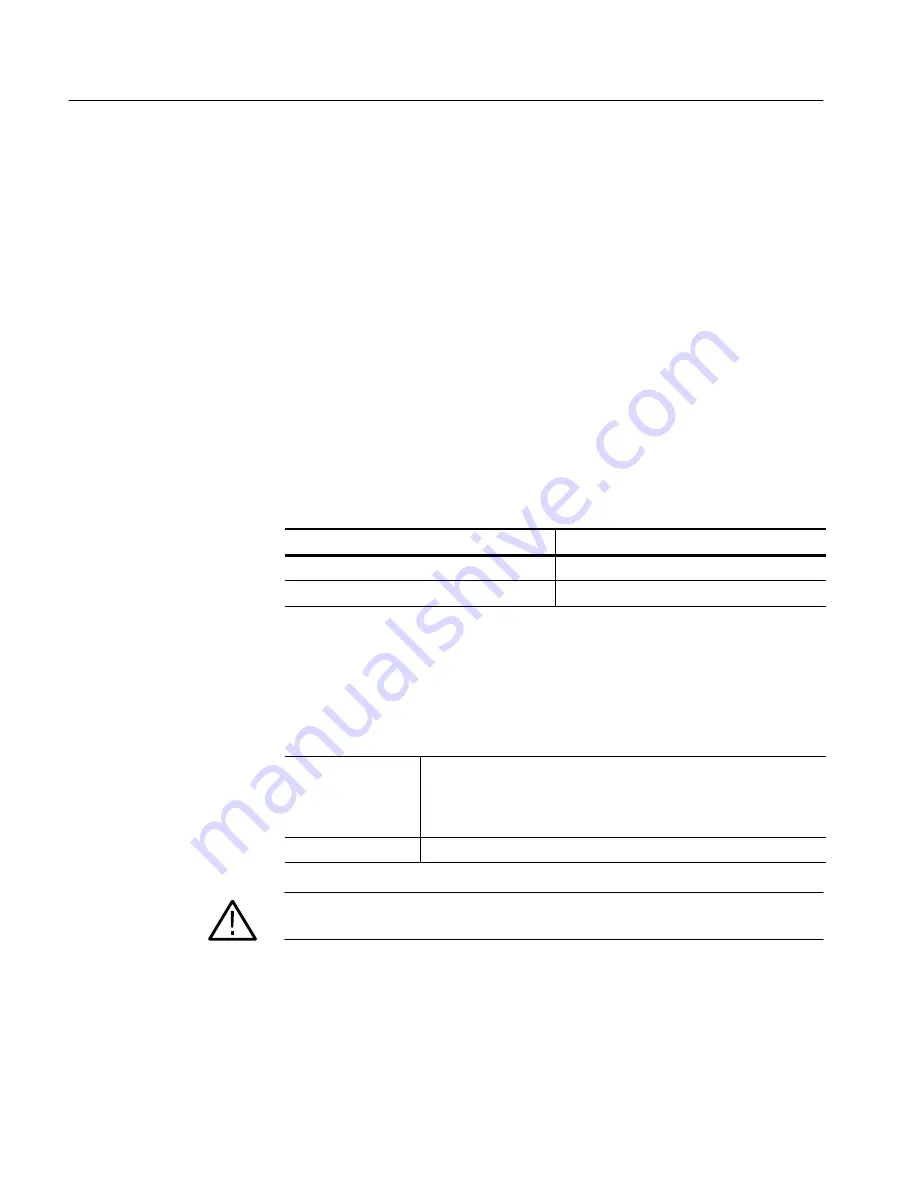

Table 4- 3: Performance verification procedures

Parameter

Procedure

Power supply voltages

Voltage level check at the 25-pin connector

System clock (CLK 10)

1

10 MHz system clock test

1

Certifiable parameter

Use a digital voltmeter to check the voltages on the pins of the 25-pin connector

and compare the results against the range listed in Table 4--4. The connector is

located on the right rear panel of the mainframe (see Figure 4--2).

Equipment

required

Digital multimeter with test leads (item 6)

Two 0.025-inch square pins (item 5)

Two miniature probe-to-square pin adapters (item 4)

Prerequisites

Warm-up time: 30 minutes

CAUTION.

To prevent damaging the 25 pin connector, use care when probing the

connector with the square pins.

Expansion Mainframe

Tests Performed

Checking Power Supply

Voltages

Summary of Contents for TLA7XM

Page 5: ......

Page 13: ...Table of Contents viii TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 17: ...Service Safety Summary xii TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 21: ...Preface xvi TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 25: ...Introduction xx TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 43: ...Specifications 1 18 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 85: ......

Page 87: ...Adjustment Procedures 5 2 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 161: ...Repackaging Instructions 6 74 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 165: ...Electrical Parts List 8 2 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 169: ...Diagrams 9 4 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...

Page 189: ...Mechanical Parts List 10 20 TLA721 Benchtop TLA7XM Expansion Mainframe Service Manual ...