ENGINE INSTALLATION

(Continued)

3 3

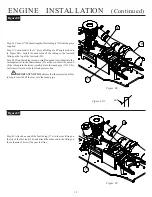

Step 5. Hook the two ends of the clutch spring (156) together to form

a loop as shown. Stretch the looped spring (156) over the two clutch

shoes (157) so that the clutch shoes (157) form a circle. Make sure

that the holes in the clutch shoes are on opposite sides of the circle

as shown

IMPORTANT NOTE:

Th clutch shoes may come in a single

piece, and must be completely separated to operate properly. Bend

the shoes along the cut and pull the two halves apart.

Tip: LIGHTLY sanding the surface of the clutch shoes can improve

their performance. Sand the shoes using a 400 grit, or finer sandpa-

per. Sand the shoe surface lengthwise, not across the shoe sideways.

DO NOT use a sanding block, or lay the sandpaper on a flat sur-

face. Too much sanding may cause flat spots to develop on the

shoes.

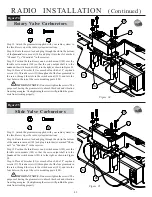

Step 6. Slide the clutch shoe assembly over the clutch nut (155). Place

each shoe (157) over a clutch pin (151) and slide the shoes (157) all

the way against the flywheel (152). In order for the shoes (157) to

slide over the clutch nut (155), they will have to be pulled apart slightly,

stretching the springs (156).

IMPORTANT NOTE:

Make sure that the clutch shoes are

facing the correct direction as illustrated. Position the clutch so that

the shoes are separated one on top, one on bottom. The top clutch

shoe should be attached to the pin at the left side of the flywheel, as

shown in Figure 75, when looking at the engine from the front.

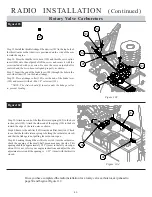

Step 7. Insert a 1/4" x 3/8" clutch bearing (158) into each side of the

clutch bell (159).

Step 8. Slide the clutch bell (159) over the clutch nut (151) so that the

gear faces out. Push the clutch bell (159) all the way against the

clutch assembly.

Step 9. Place the clutch spacer (160) over the clutch nut (151) and

against the clutch bell (159). Secure the assembly by pushing the 1/4"

clutch nut clip (161) over the end of the clutch nut (151) and into the

groove in the clutch nut (151).

IMPORTANT NOTE:

The bearings used in the clutch con-

tain a special grease that does not migrate. It is important that these

bearings only be replaced with Team Losi's replacement clutch bear-

ings. It is also important not to oil the bearings in the clutch. Any oil

that is put on the bearings can find its way into the clutch assembly

and cause the clutch to slip.

Figure 74

Figure 75

Figure 76

Figure 74

157

156

157

155

152

156

151

Figure 75

151

160

159

161

158

158

Figure 76

160

158

161