Tape elevons

Attaching the lightweight elevons to the wing is done using flexible tape. Any thin tape will do, but it is

recommended to use 3M Blenderm Hinge Tape or similar type.

Add one long piece of tape to the inside of the elevon and attach it to the wing. Bend the elevon down to

expose the topside. Add another long piece of tape to this side. Move the elevon up and down a few times

to compact and soften the hingje.

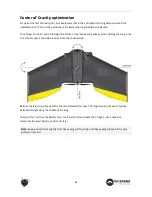

The inner end of the hinges should follow the arc from the frame, in-line with the frame. Leaving a small

cap between the winglet and elevon.

16