408- 1559

7

of 10

Rev

T

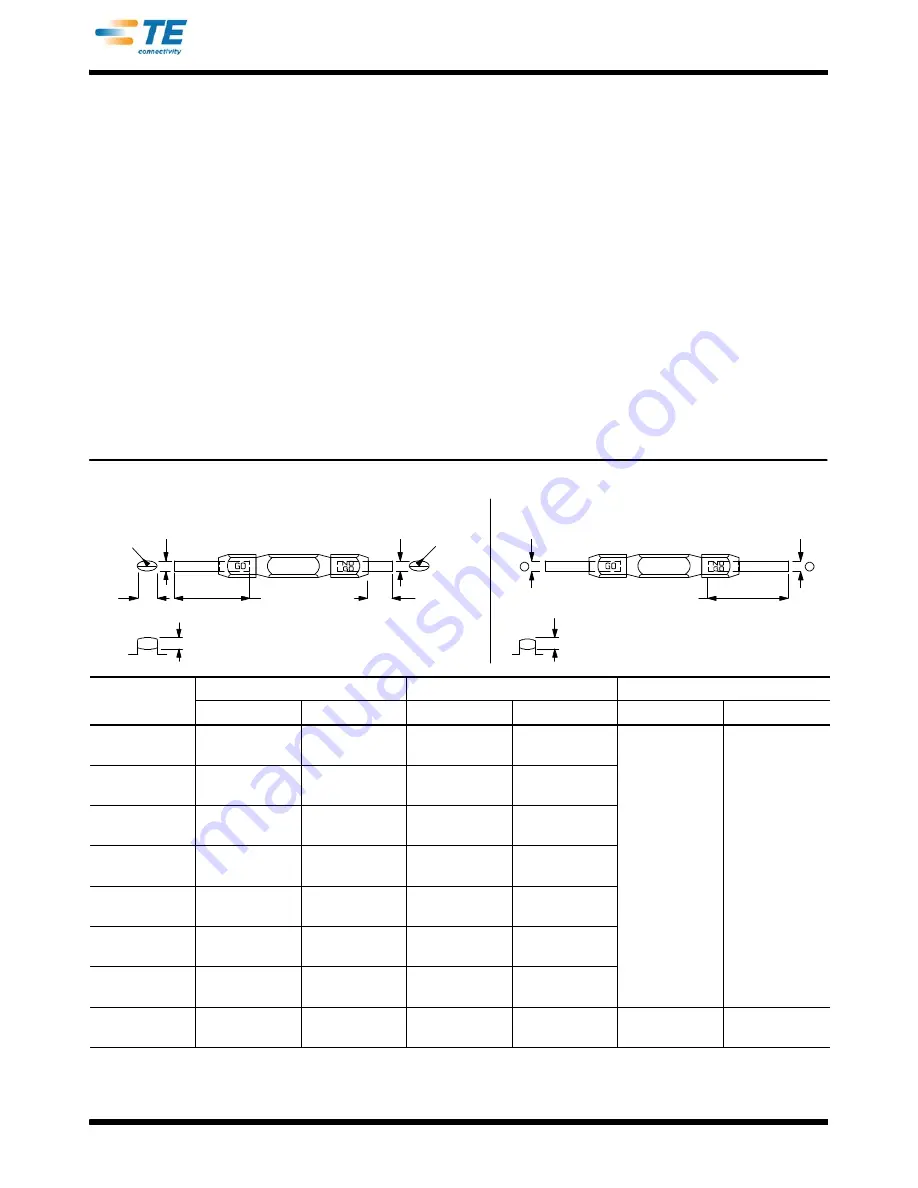

B. Gaging Crimping Chamber

This inspection requires the use of plug gages

conforming to the dimensions listed in Figure 8. To

gage the crimping chamber, proceed as follows:

1. Close the jaws by squeezing the tool handles

together until the jaws have bottomed, and then

HOLD the handles in this position. DO NOT force

the jaws beyond initial contact.

2. Align the GO element of the gage with the wire

barrel crimp section of the crimping chamber. Refer

to Figure 9. Push the element straight into the

crimping chamber without using force. The GO

element must pass completely through the

crimping chamber.

3. Align the NO--GO element of the gage with the

same crimp section, and try to insert the element.

The NO--GO element may start entry, but it must

not pass completely through the crimping chamber.

Refer to Figure 9.

4. Repeat the gage inspection for the insulation

crimp section of the crimping chamber, making

sure to use the correct plug gage.

If the crimping chamber conforms to the gage

inspection, the tool is considered dimensionally

correct. If the crimping chamber does not conform to

the inspection, the tool must be repaired. Refer to

Section 6, REPLACEMENT AND REPAIR.

For additional information concerning the use of the

plug gage, refer to instruction sheet 408--7424.

C. Ratchet Inspection

Obtain a .025--mm [.001--in.] shim that is suitable for

checking the clearance between the bottoming

surfaces of the jaws. To inspect the ratchet control,

proceed as follows:

1. Refer to Figure 3, and select a product and

maximum size wire.

R

(Typ)

12.7 [.50]

Min Typ

31.75 [.125]

Min Typ

Tool 69454

Jaw Closure

Configuration

Jaw Closure

Configuration

50.8 [2.00]

Min Typ

Suggested Plug Gage Design — Wire Barrel Crimp Section

A

A

C

(Max)

B

(NO--GO)

B

(GO)

R

(Typ)

All Other Tools

B

(NO--GO)

B

(GO)

TOOL

JAW CLOSURE

{

DIAMETER A

GAGE ELEMENT

{{

DIAMETER B

DIMENSION

TOOL

GO

NO--GO

GO

NO--GO

C (Width)

R (Radius)

46121

--0

169485

--

1.600 [.0630]

1.753 [.0690]

1.600--1.608

[.0630--.0633]

1.750--1.753

[.0689--.0690]

47304

--0

1.600 [.0630]

1.753 [.0690]

1.600--1.608

[.0630--.0633]

1.750--1.753

[.0689--.0690]

47386

--0

47386--5

2.768 [.1090]

2.921 [.1150]

2.768--2.776

[.1090--.1093]

2.918--2.921

[.1149--.1150]

47387

68343--1

3.022 [.1190]

3.175 [.1250]

3.022--3.030

[.1190--.1193]

3.172--3.175

[.1249--.1250]

—

—

47907--1

2.260 [.0890]

2.413 [.0950]

2.260--2.268

[.0890--.0893]

2.410--2.413

[.0949--.0950]

48518--2

1.600 [.0630]

1.753 [.0690]

1.600--1.608

[.0630--.0633]

1.750--1.753

[.0689--.0690]

69151--1

2.768 [.1090]

2.921 [.1150]

2.768--2.776

[.1090--.1093]

2.918--2.921

[.1149--.1150]

69454

--0

2.616 [.1030]

2.718 [.1070]

2.616--2.624

[.1030--.1033]

2.715--2.718

[.1069--.1070]

3.962 [.156]

3.454 [.136]

Figure 8 (Cont’d)

{

Jaw closure dimensions apply when wire barrel jaws are bottomed, but not under pressure.

{{

Material: Tool Steel