409-32023

Rev

B

15 of 41

If both boxes are not checked, the machine will complete the verification process and enter production

when there is no smart applicator connected, but an error/warning will be displayed (click the OK

button to continue).

For possible error messages and solutions, refer to Figure 18.

SMART APPLICATOR ERROR MESSAGE

DESCRIPTION

POSSIBLE SOLUTION

"Crimp Height Not Supported"

Crimp height specified for the wire in

the terminal editor does not match

the smart applicator data.

1.

Verify the crimp height in the terminal editor is

matched in the smart applicator data.

2.

Turn off “Allow only Smart Applicator data for

Crimp Height” in the Options editor to allow

production with a non-standard crimp height.

“Cross Section Not Supported”

The wire cross section specified for

the wire in the terminal editor does

not match the smart applicator data.

1.

Verify the wire cross in the terminal editor is

matched in the smart applicator data.

2.

Turn off “Allow only Smart Applicator data for

Cross Section” in the Options editor to allow

production with a non-standard cross section.

"No Applicator Connected"

No applicator was detected on the

station or terminator.

1.

Plug in the applicator.

2.

Turn off “Allow only Smart Applicator data for

Cross Section” and “Allow only Smart Applicator

data for Crimp Height” in the Options editor to allow

production without a smart applicator attached.

3.

Check that the smart applicator setting for the

terminator is configured correctly for the precision

controller connection or an applicator direct

connection.

“Register Failed”

The precision controller and the

machine failed to initialize the

communication.

1.

Check that the air feed signal from the terminator to

the precision controller is connected properly.

2.

Check that the precision controller is configured

properly in the options editor of the TopWin software.

3.

Check that the IP address on the precision controller

is configured properly.

“Load Data”

Data is transferred from the smart

applicator to TopWin software.

1.

This is normally shown, momentarily.

2.

If the transfer fails, another error will appear.

“Applicator Maintenance is Needed

(SN:691905)”

One of the tool counters in the smart

applicator has exceeded its targets.

Go to the Smart Applicator Maintenance screen, and

reset the tool count.

Figure 18

It is important for the operation of the smart applicator features that the Compulsory Verifying option

be turned on (Option editor > Machine > Verify > Activate).

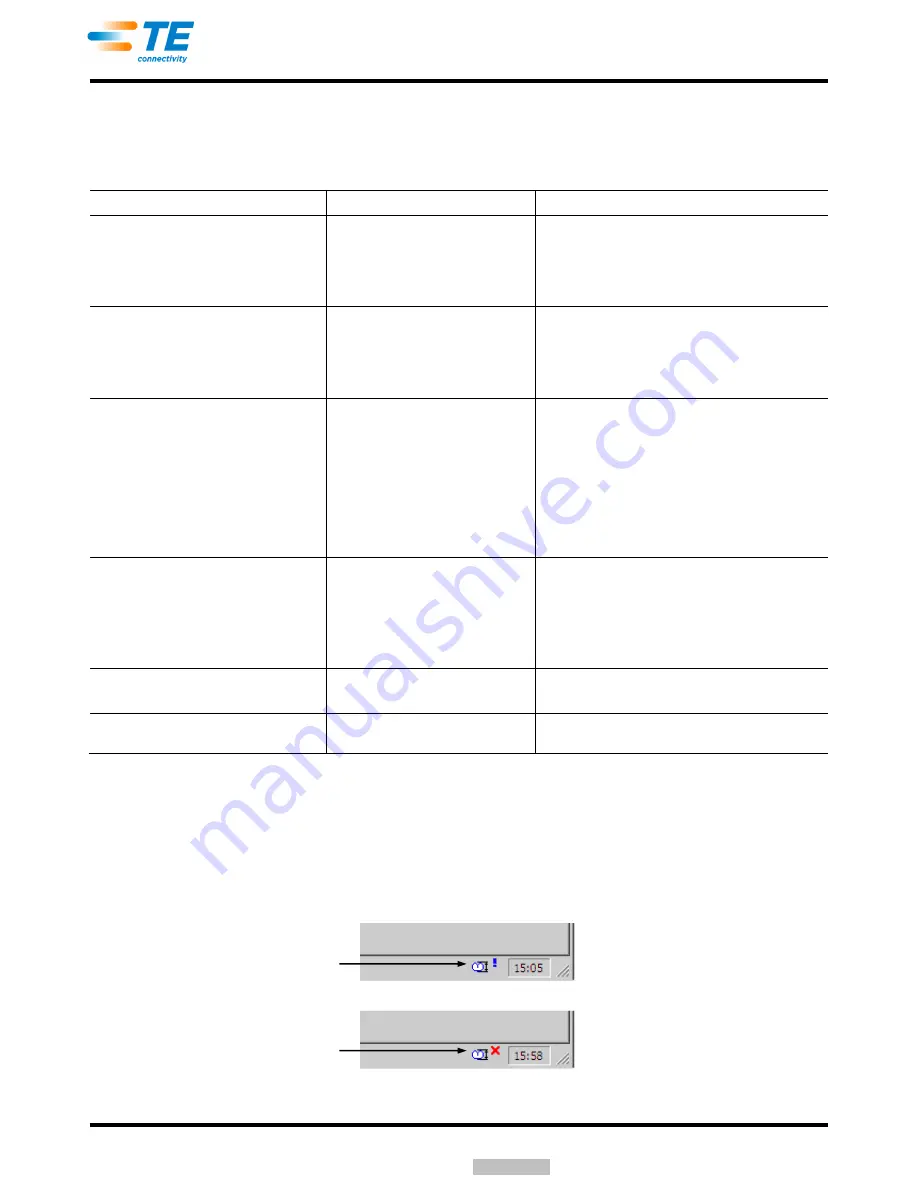

When the Compulsory Verifying option is not turned on, the Verify Crimp Height icon at the bottom of

the screen will appear with an exclamation point. See Figure 19. In this mode, the TopWin software

will allow the operation of the smart applicator without fully verifying the crimp height.

Figure 19

Compulsory Verification Option Off

Compulsory Verification Option On

Downloaded From