R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

9

Programming - Pulse Meter

The utility pulse meter module portion of this panel is an

SEQ100.

METER INPUTS

There are four meter inputs available. Each one is setup

for a dry contact and cannot be changed. Each input

(Meter 1, Meter 2, Meter 3 & Meter 4) can be configured

to accept signals representing electrical, BTU, water or

gas usage. The required parameters will be provided

by either the utility company involved or on the current

transducer (CT) used to generate the pulse signal.

METER TYPES

The SEQ100 supports various meter types. Selecting a

meter type changes the default values as they are used

to calculate meter consumption and demand for that par-

ticular meter. For each of the four SEQ100 meter inputs,

there are five selectable options:

ELEC 1 PH: Electric single phase meter.

ELEC 3 PH: Electric three phase meter.

GAS: Gas meter.

WATER: Water meter

BTU: BTU meter

Utility pulse meters can be one of two different types,

depending on whether they count the leading and trail-

ing edges of the pulse or only the leading edge of the

pulse as a single count. A pulse output can be either a

mechanical relay or solid state device. The pulse output

corresponds to a unit/time of a monitored quantity. The

amount of time between states of a pulse output corre-

sponds to the meter demand and the number of pulses

is proportional to the meter’s consumption.

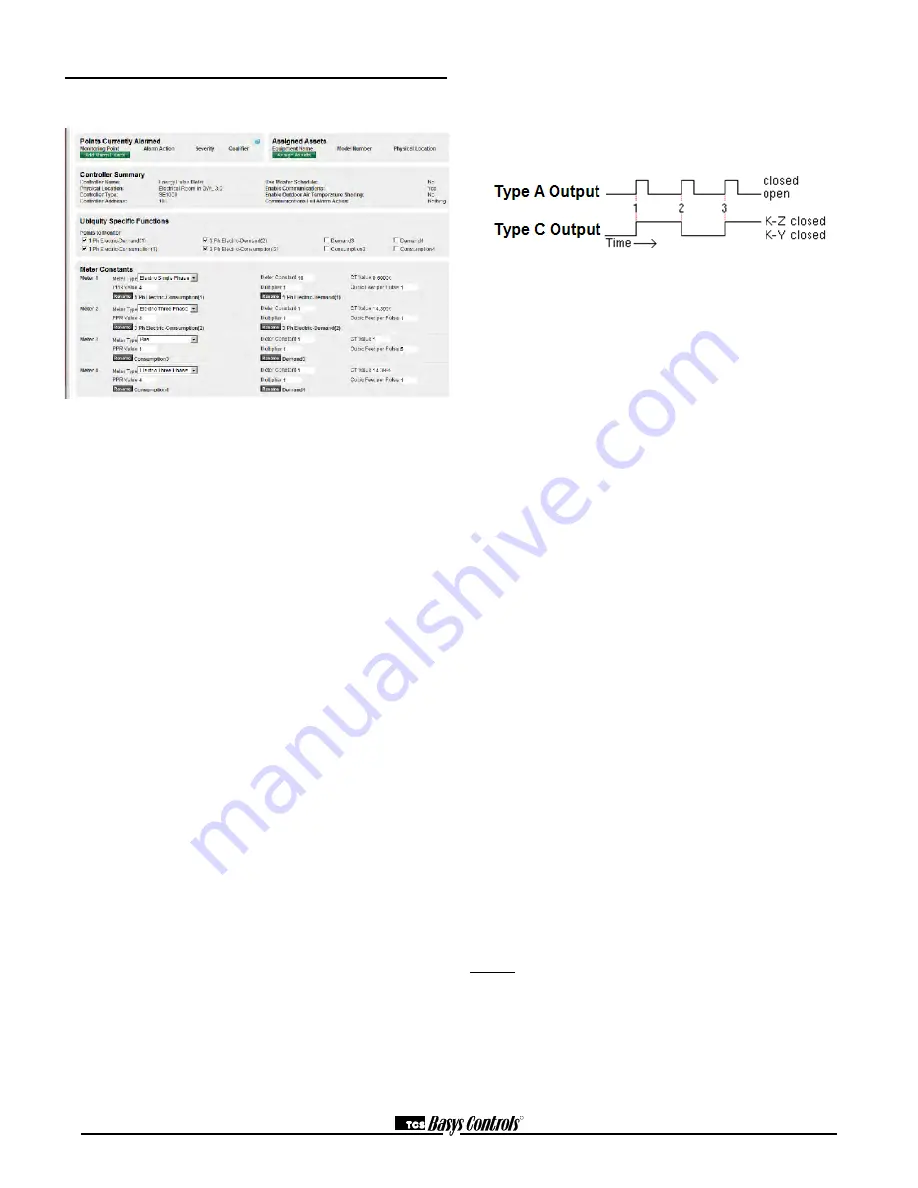

Below is a diagram depicting two types of utility meter

pulse outputs. Meter Type A counts only the leading

edge as a single pulse and the trailing edge is ignored.

Meter Type C is known as a true KYZ meter and counts

both the leading and trailing edges as a pulse, effectively

doubling the number of pulses as seen by Meter Type

A. The SEQ100 measures Type A output only; however,

KYZ functionality can be mimicked by using a “Meter

Multiplier” value of 2.

In the following picture, both Type A and C are shown.

Three pulses are shown, labelled 1, 2, and 3. Notice

how the Type A output closes and opens for each pulse,

where the Type C output simply changes state.

If you have a Type C device (3 terminals KYZ), you will

need to double the multiplier. The SEQ100 only counts

the contact closures for the K and Z terminals. Doubling

the multiplier will correct this problem.

PROGRAMMING THE METER CONSTANTS:

CT Value: The value of the CT wired to the meter. This

value is usually provided on the CT or on the utility out-

put meter. This value is only used for and electric meter.

P/REV: The Pulses per revolution for the meter. This

value is usually provided from the utility company.

CONSTANT: The value of the constant for the meter

is usually provided from the utility company and many

times is located on the electric or gas bill.

CU FT/P: The value for Cubic Feet per pulse. This only

applies to Water, GAS and BTU, and is usually found on

the utility meter itself.

MULT: The multiplier for the meter can be used to scale

the meter output or correct for KYZ meter. The multi-

plier is used to convert the pulses to engineering unit

data. For example, if your meter provides one pulse per

0.01KWH, then a constant of 0.01 is required.

MULTIPLIER:

Each model of power meter is different and has a differ-

ent multiplier. For example, if the meter is a Type A and

reports 1/10 kWh per pulse, set the input multiplier to

0.1. If the meter is a Type C and reports 1/10 kWh per

pulse, set the input multiplier to 0.2.

You must obtain the correct pulse multiplier from the

meter manufacturer prior to configuring the SEQ100.

Some power meters have an option to configure the mul-

tiplier. Options often include 1, 0.1, 0.01, kWh per pulse.

The best method to configure the pulse is to select the

smallest multiplier available, considering the maximum

load and pulse rate. To calculate the pulse rate, use the

following formula:

Pulses = KW*3600*multiplier

Second