R

2800 LAURA LANE • MIDDLETON, WI 53562 • (800) 288-9383 • FAX (608) 836-9044 • www.tcsbasys.com

10

In general, the SEQ100 calculates electric meter con-

sumption and demand as follows:

Demand = (CTValue*MtrConst*MtrMult)

(PPRValue*PulseTimeDiff)

Consumption = (PulseCount*CTValue*MtrConst*MtrMult)

PPRValue

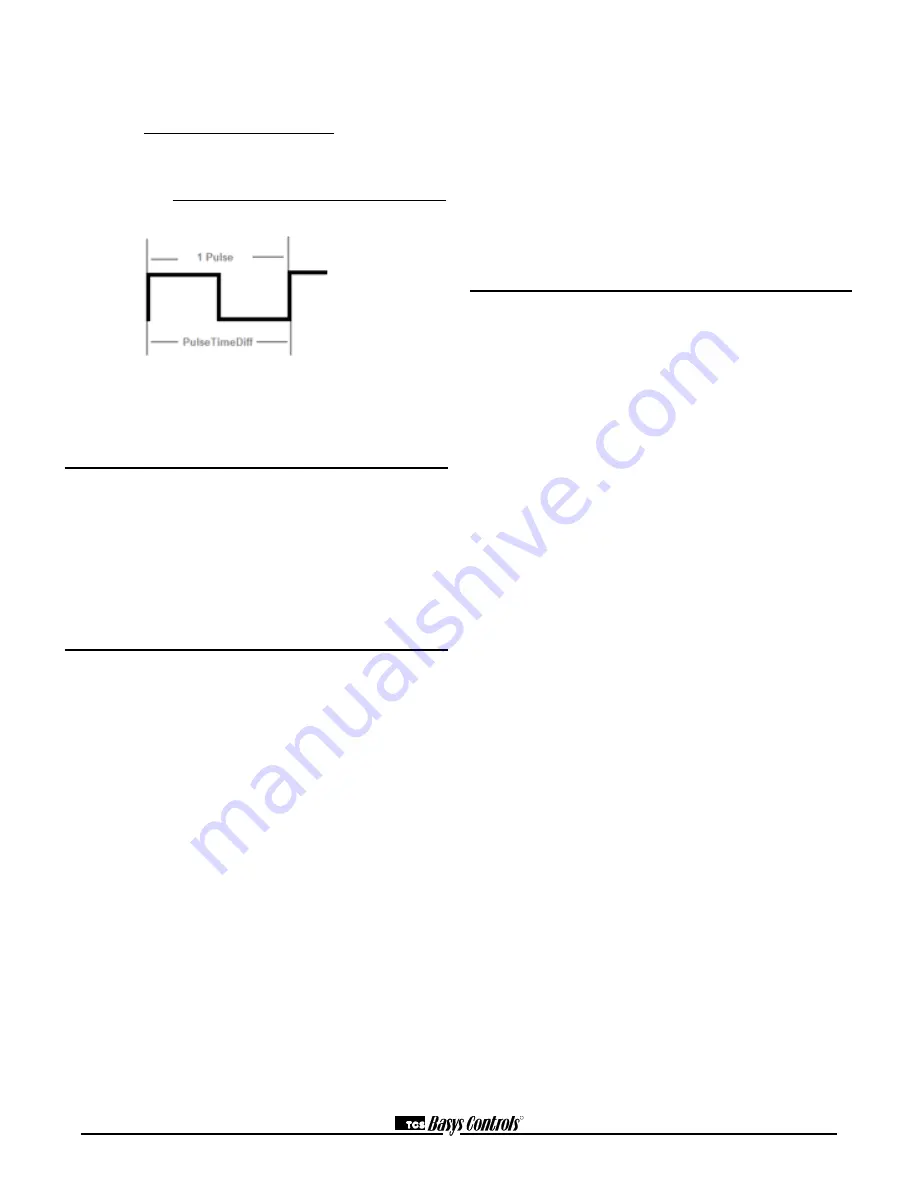

The above diagram depicts how a single pulse and the

pulse time difference are represented on a pulse wave-

form input into the SEQ100.

TCS ZigBee Wireless Network

The QWL 3.1 Rev 2 can be bundled with a QW1010 TCS

ZigBee wireless gateway to manage the TCS ZigBee

wireless network. Be sure to plug the USB cable into one

of the QWL 3.1 Rev 2 USB ports and configure it for the

TCS protocol before initiating the wireless controllers.

The QW1010 will also need to be properly setup before

the wireless network will communicate (Please refer to

the QW1010 Product Manual).

LED Display and Push Buttons

Fourteen LEDs on the QWL 3.1 Rev 2 series panel allow

the user to view the current operating status of the QWL

3.1 Rev 2 series panel.

DIGITAL OUTPUTS: Along the Left hand side there are

Eight LEDs and Push button

•

The LEDs will be lit when the corresponding relay

output is occupied, or physically on no matter if the

channel is selected to be NO or NC.

•

The push buttons correspond to each of the channels

for the timed override function.

DATA: Along the Right hand side towards the

bottom, there are three LEDs

•

The RX LED indicated that the SEQ100 and SLQ218

are in Receive mode.

•

The TX LED indicated that the SEQ100 and SLQ218

are in transmit mode.

•

The Wireless LED- NOT USED

ALARM: This LED indicates that a local alarm is

active

POWER: This LED indicated that the QWL 3.1 Rev 2

series panel has power applied

•

The reset button in the lower right hand corner is

used to “reboot” the entire QWL 3.1 Rev 2 series

panel. This is accomplished by pushing and holding

the button for 5-7 seconds.

Note: During a reboot, the lights associated with

the Lighting Module of this product could go out, it is

recommended that you open the panel and place the

Hand-Off-Auto switch for the corresponding channel in

the Hand position to ensure that the lights that should be

on remain on.

CPU: This LED indicates that the CPU or QD2040 portion

of the panel is active and running.

Checkout & Troubleshooting

QWL 3.1 Rev 2 series panel

• Be sure to check and verify all wiring before

powering up the QWL 3.1 Rev 2 series panel

• The QWL 3.1 Rev 2 series panel is designed to

contain 24 VAC devices and wiring ONLY. No line

voltage (120 VAC or greater) is to be installed

within this panel.

• If you created metal shavings, ensure they are

cleaned up and not in a position to allow for

shorting before powering up.

Lighting Module - SLQ218

• Verify all wiring before powering up the QWL 3.1

Rev 2 series panel and the SLQ218.

• Place the Hand-Off-Auto switches in the off

position

• Place the appropriate (Normally Open) NO or

(Normally Closed) NC jumpers (both included)

in position-RED wires = NO-ON=Closed and

BLACK wires=NC-On=Open

Utility Meter Pulse Transducer Module - SEQ100

• Verify all wiring prior to powering the QWL 3.1

Rev 2 series panel and SEQ100.

• Take note of the current readings for all meters.

Since the SEQ100 is used for only monitoring,

and is the reading appear to be correct, you are

done.

• If a value does not appears to be correct, verify

on the programming page the value programmed

in is correct.

• If a value is shown as 0 (Zero) the SEQ100 is not

receiving a pulse signal.

Site Communications Center - QD2040

• Be sure to verify all wiring and programming

information before hooking up to Network

• If the CPU LED does not light up, verify that the

power supply nodule (included with the QWL 3.1

Rev 2 series panel) is plugged in to an outlet that

has power.