OPERATING PROCEDURES

6-5

Model 104

Operating Procedures

6

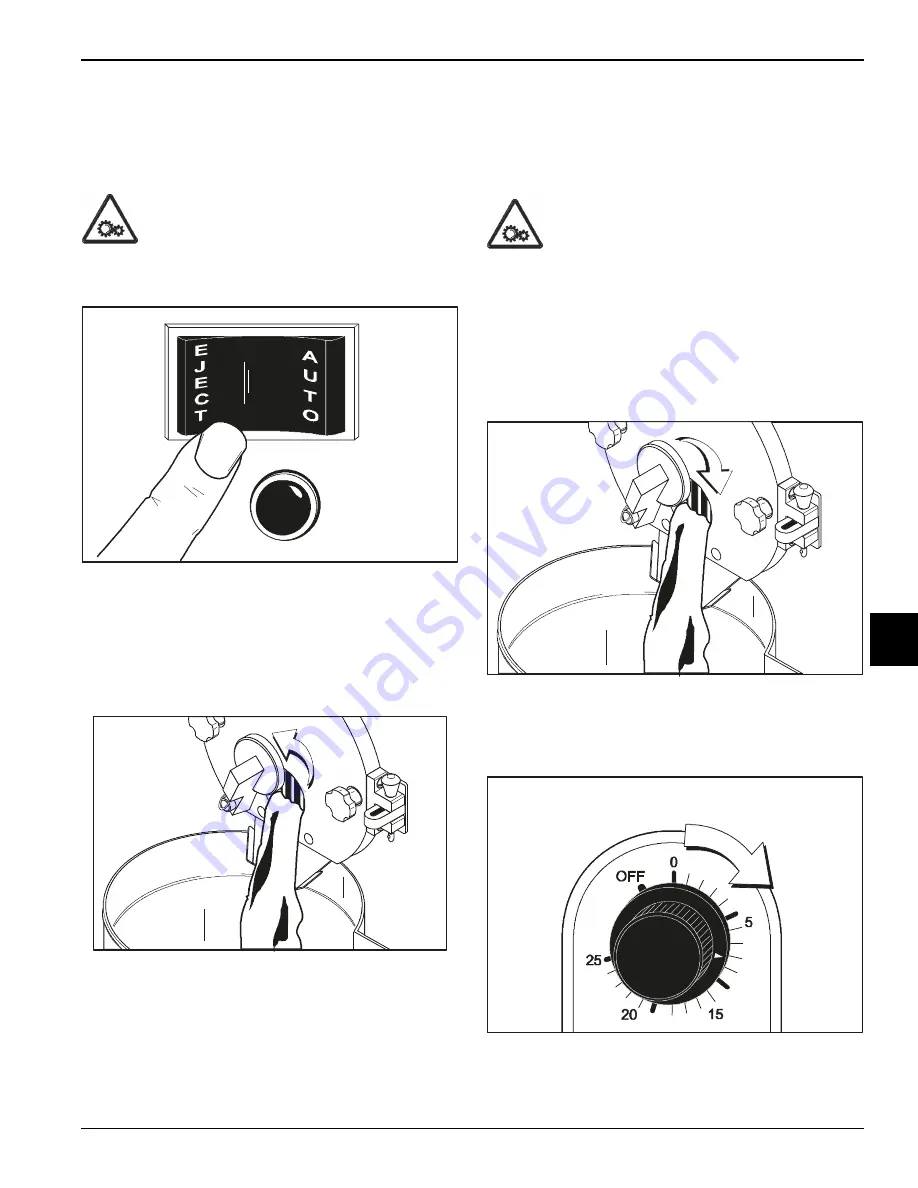

5. Put the control switch into the EJECT position.

This causes the sanitizing solution in the freezing

cylinder to be agitated. Allow it to agitate for five

minutes.

WARNING!

Keep fingers out of fill and

discharge openings. Failure to do so may result in

personal injury or component damage.

Figure 6-20

6. Put the control switch into the off position.

7. Hold a pail beneath the ejection port, open the draw

arm, and drain the sanitizing solution from the

freezing cylinder.

8. Close the draw arm.

Figure 6-21

Priming

1. With the control switch in the off position, hold an

empty pail beneath the ejection port and open the

draw arm.

WARNING!

Keep fingers out of fill and

discharge openings. Failure to do so may result in

personal injury or component damage.

2. Pour the desired amount of mix into the funnel. The

mix in the freezing cylinder will force out any

remaining sanitizing solution.

3. When full-strength mix is flowing from the ejection

port, close the draw arm.

Figure 6-22

4. Set the timer for the time required for the batch. Allow

the unit to operate until the buzzer sounds and the

refrigeration system automatically cycles off.

Figure 6-23

5. Place the control switch in the AUTO position.

13014

10141

10141a

10142

Summary of Contents for 104

Page 8: ...1 4 TO THE INSTALLER Model 104 To the Installer 1 Notes...

Page 14: ...3 4 SAFETY Model 104 Safety 3 Notes...

Page 18: ...4 4 PARTS Model 104 Parts 4 Notes...

Page 30: ...7 2 OPERATOR CHECKLIST Model 104 Operator Checklist 7 Notes...

Page 32: ...8 2 TROUBLESHOOTING Model 104 Troubleshooting 8 Notes...

Page 34: ...9 2 PARTS REPLACEMENT SCHEDULE Model 104 Parts Replacement Schedule 9 Notes...

Page 40: ...11 4 LIMITED WARRANTY ON PARTS Model 104 Limited Warranty on Parts 11 Notes...