6-6

OPERATING PROCEDURES

Model 104

Operating Procedures

6

6. Remove the funnel and close the mix inlet cover.

Figure 6-24

Overrun

Depending on the overrun desired, the amount of

pre-charge can range from 1.5 qt. to 3 qt. (1.4 L to 2.8 L).

This gives an overrun between 20% and 100%. Overrun

which exceeds 100% must not be taken below

26ºF (-3.3ºC) or the product will not eject. Depending on

the mix, product overrun below 100% may be taken as

low as 18ºF (- 7.7ºC) with no ejection problem. If ejection

problems do exist, then the product has been taken too

cold.

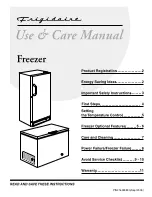

Place the control switch in the EJECT position and take a

sample of the product to determine overrun. If the

overrun is

not

at the desired level, leave the control

switch in the EJECT position to agitate the product and

blend more air into the mixture. Continue to take samples

until the desired overrun is obtained.

Figure 6-25

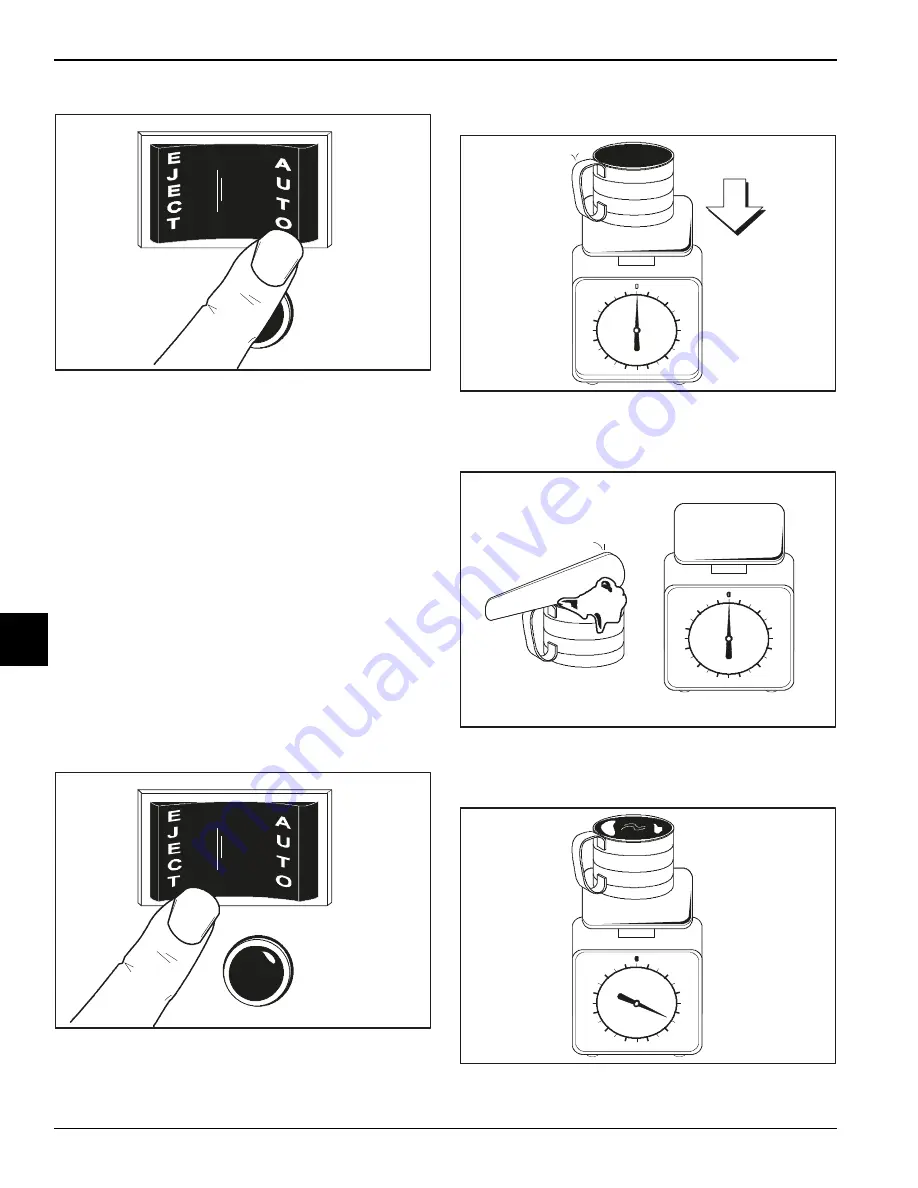

1. Use a standard overrun scale and a one-pint

measuring cup.

2. Place an empty cup on the scale and adjust the scale

pointer to the zero setting.

Figure 6-26

3. Draw off one pint of frozen product. With a

straightedge, level off the top.

Figure 6-27

4. Place the pint of product on the scale. Read the

overrun directly off the scale.

Figure 6-28

13014a

13014

17069

17023

17024

Summary of Contents for 104

Page 8: ...1 4 TO THE INSTALLER Model 104 To the Installer 1 Notes...

Page 14: ...3 4 SAFETY Model 104 Safety 3 Notes...

Page 18: ...4 4 PARTS Model 104 Parts 4 Notes...

Page 30: ...7 2 OPERATOR CHECKLIST Model 104 Operator Checklist 7 Notes...

Page 32: ...8 2 TROUBLESHOOTING Model 104 Troubleshooting 8 Notes...

Page 34: ...9 2 PARTS REPLACEMENT SCHEDULE Model 104 Parts Replacement Schedule 9 Notes...

Page 40: ...11 4 LIMITED WARRANTY ON PARTS Model 104 Limited Warranty on Parts 11 Notes...