Motor SEM

Page 79

MR-380-05

RE-380-36 & RE-380-48

INSPECT

Brushes

Measure the length of each motor brush.

•

If any one brush is less than or equal to the

service limit specified in section Service Limits,

then all four brushes should be replaced. Refer

to Replacing the Brushes section for information

regarding replacing the motor brushes.

•

A burnt brush lead is an indication of excessive

motor current or another brush was stuck in the

brush holder, not in contact with the commutator.

Bearing

A faulty or worn bearing is typical a accompanied with

a report of noise from the motor that could be called a

growl or grinding noise and is best diagnosed while in

the vehicle using a mechanics stethoscope.

Since disassembly of the motor typical damages the

bearing, the bearing should be replaced whenever the

motor is disassembled.

Commutator

Measure the diameter of the commutator.

•

If the commutator is less than the minimum

diameter specified in section Service Limits, then

the motor must be replaced.

Measure the commutator undercut depth in 5-places

around the commutator.

•

If any one of the measurements is less than the

minimum undercut depth specified in Service

Limits at the end of this section, then the

commutator must be undercut. Refer to Repair

Commutator section for information regarding

undercutting the commutator.

This section is one section of a complete service

manual. Before starting any procedure, read all

warnings and instructions that are located in the

Service Guidelines chapter.

WARNING

Inspect the commutator for groves.

•

If the commutator is grooved then it must be

machined on a lathe. Do not machine the

commutator past the minimum diameter specified

in Service Limits section. Refer to Repair

Commutator section for information regarding

machining the commutator.

Inspect the commutator for burn marks.

•

Burn marks and/or raised commutator segments

90 or 180 degrees apart is evidence of a shorted

armature. A tool called a growler is required to

reliably test for a shorted armature.

Inspect the commutator for raised segments. Raised

segments could be a result of a stalled motor or shorted

armature. A tool called a growler is required to reliably

test for a shorted armature.

•

If the armature is not shorted then the raised

segments can be removed by machining the

commutator. Do not machine the commutator

past the minimum diameter specified in Service

Limits at the end of this section. Refer to Repair

Commutator section for information regarding

machining the commutator.

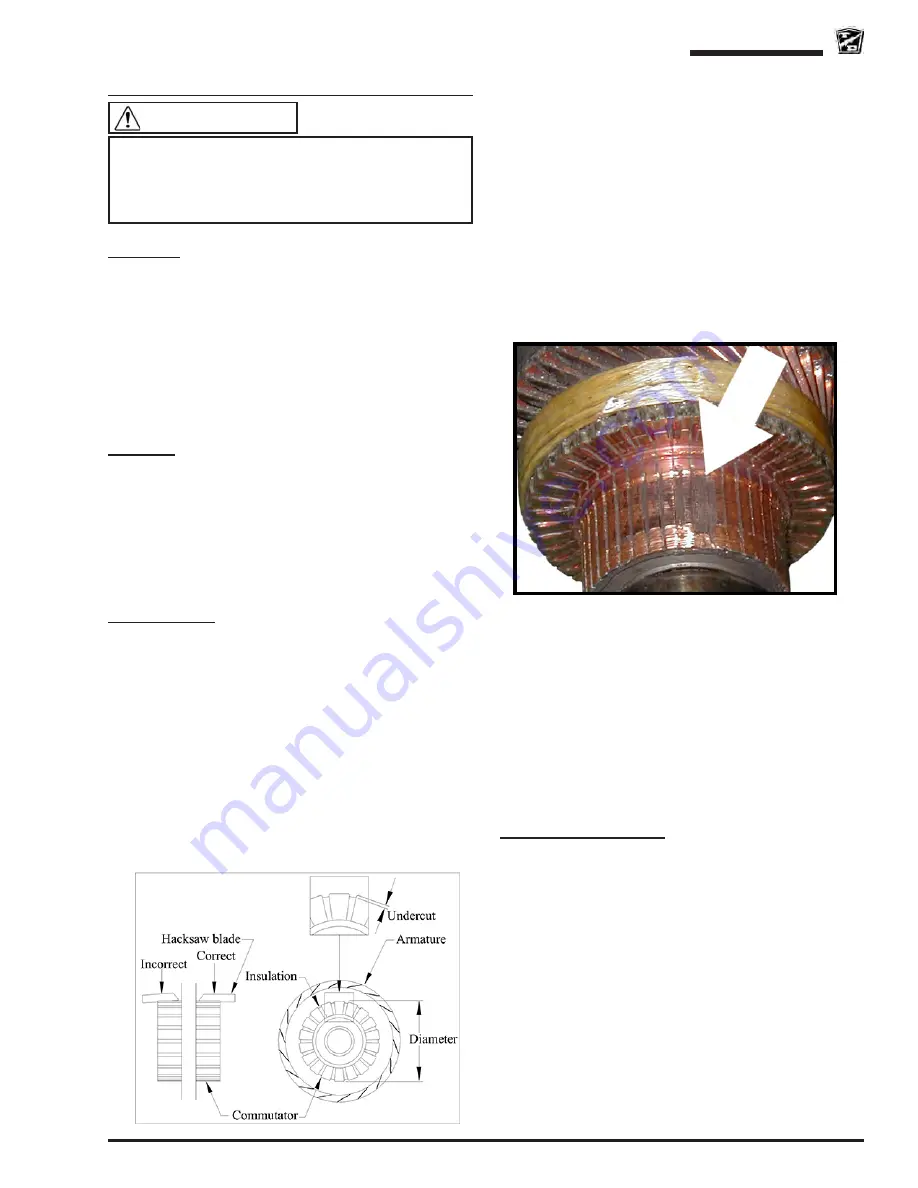

Armature Windings

Visually inspect the armature windings for burnt

insulation. Burnt insulation is a direct result of motor

overheating and could lead to a shorted armature.

•

If the insulation is cracked or burnt, then it is

recommend that the armature or motor be

replaced.

Note: If the armature has been burnt then there

is a good possibility that the field windings

may also be burnt. Symptoms indicating a

shorted field include high motor current, lack

of power and possibly excessive speed.

Summary of Contents for RE-380-36

Page 6: ......

Page 12: ...Page 12 MR 380 05 Introduction RE 380 36 RE 380 48 Notes...

Page 28: ...Lubrication Page 28 RE 380 36 RE 380 48 MR 380 05 Notes...

Page 55: ...Transaxle SD Page 55 MR 380 05 RE 380 36 RE 380 48...

Page 65: ...Steering Page 65 MR 380 05 RE 380 36 RE 380 48 Exploded View of Steering Gear...

Page 89: ...Wire Diagram Page 89 RE 380 36 RE 380 48 RE 380 36 RE 380 48...

Page 90: ...Wire Diagram Page 90 RE 380 36 RE 380 48 RE 380 36 RE 380 48 Notes...

Page 102: ...Tires Wheels Page 102 RE 380 36 RE 380 48 MR 380 05 Notes...

Page 114: ...Replacement Parts Page 114 MR 380 05 RE 380 36 RE 380 48 GT TRANSAXLE ASSEMBLY REAR...

Page 118: ...Replacement Parts Page 118 MR 380 05 RE 380 36 RE 380 48 BATTERY...

Page 120: ...Replacement Parts Page 120 MR 380 05 RE 380 36 RE 380 48 BRAKES BRAKE LINES...

Page 144: ...Replacement Parts Page 144 MR 380 05 RE 380 36 RE 380 48 STEERING LINKAGE...

Page 149: ......