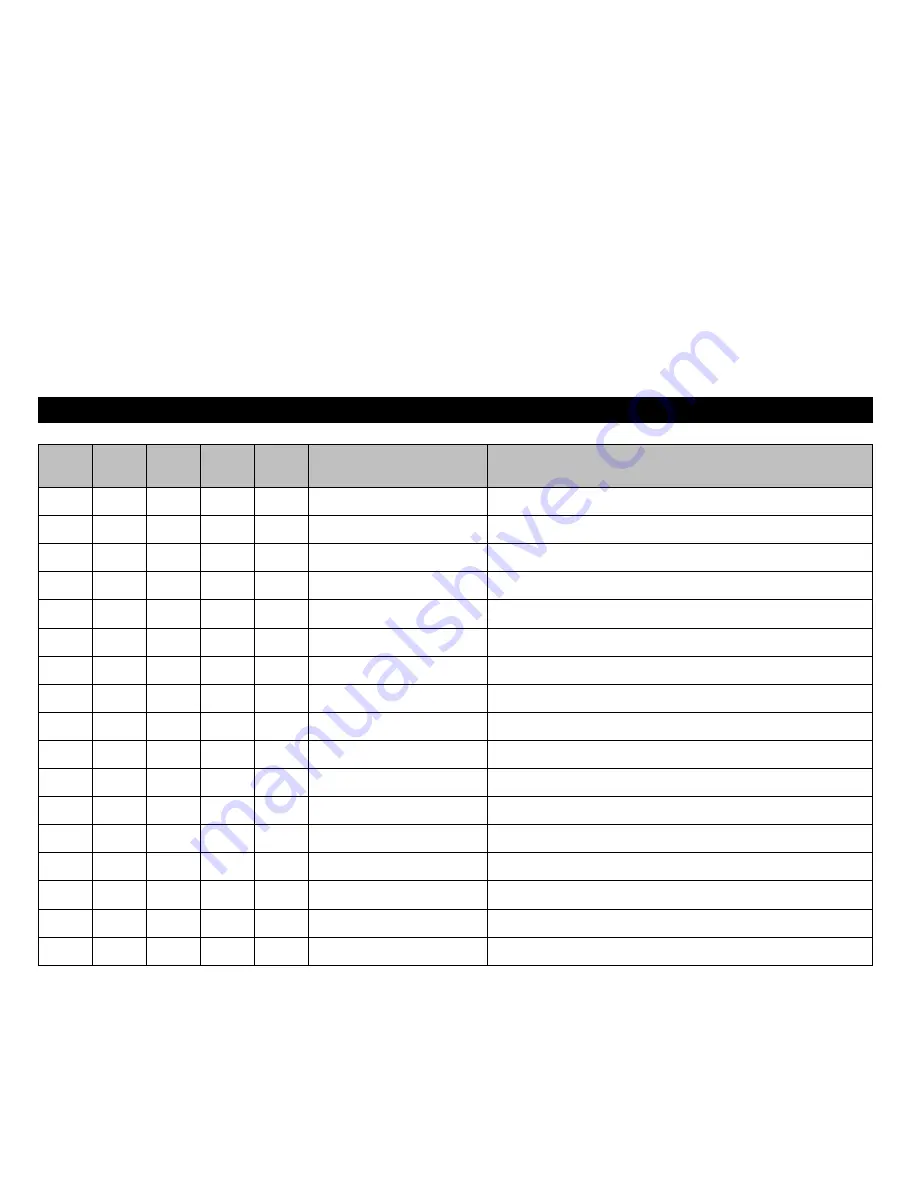

MTPL

IBM

XL24

IBM

AGM

Epson

LQ-2550

Epson

LQ-2170

Code

Function

✓

<ESC>(c

Defining the page format

✓

<ESC>(v

Relative vertical printing position

✓

<ESC>(t

Assigning a character table

✓

✽

✽

✽

✽

<ESC>(m

Character set BRASCII

✓

✽

✽

✽

✽

<ESC>(n

Character set Abicomp

✓

✽

✽

✽

✽

<ESC>(p

Windows character set 1250 (Latin2)

✓

✽

✽

✽

✽

<ESC>(q

Windows character set 1251 (Cyrillic)

✓

✽

✽

✽

✽

<ESC>(r

Windows character set 1252 (Latin1)

✓

✽

✽

✽

✽

<ESC>(t

Windows character set 1254 (Turkish)

✓

✽

✽

✽

✽

<ESC>(‘

Character set Norwegian

✓

✽

✽

✽

✽

<ESC>(A

Character set UK-ASCII

✓

✽

✽

✽

✽

<ESC>(B

Character set US-ASCII

✓

<ESC>(C

Defining the page length

✓

✽

✽

✽

✽

<ESC>(F

Assign character set G0

✓

<ESC>(G

Selecting graphics mode

✓

✽

✽

✽

✽

<ESC>(H

Character set Swedish-Finnish

✓

✽

✽

✽

✽

<ESC>(K

Character set German

Reference manual

Emulations

138