3 Technical data

34

TW9

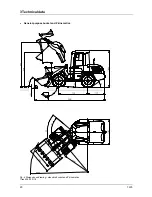

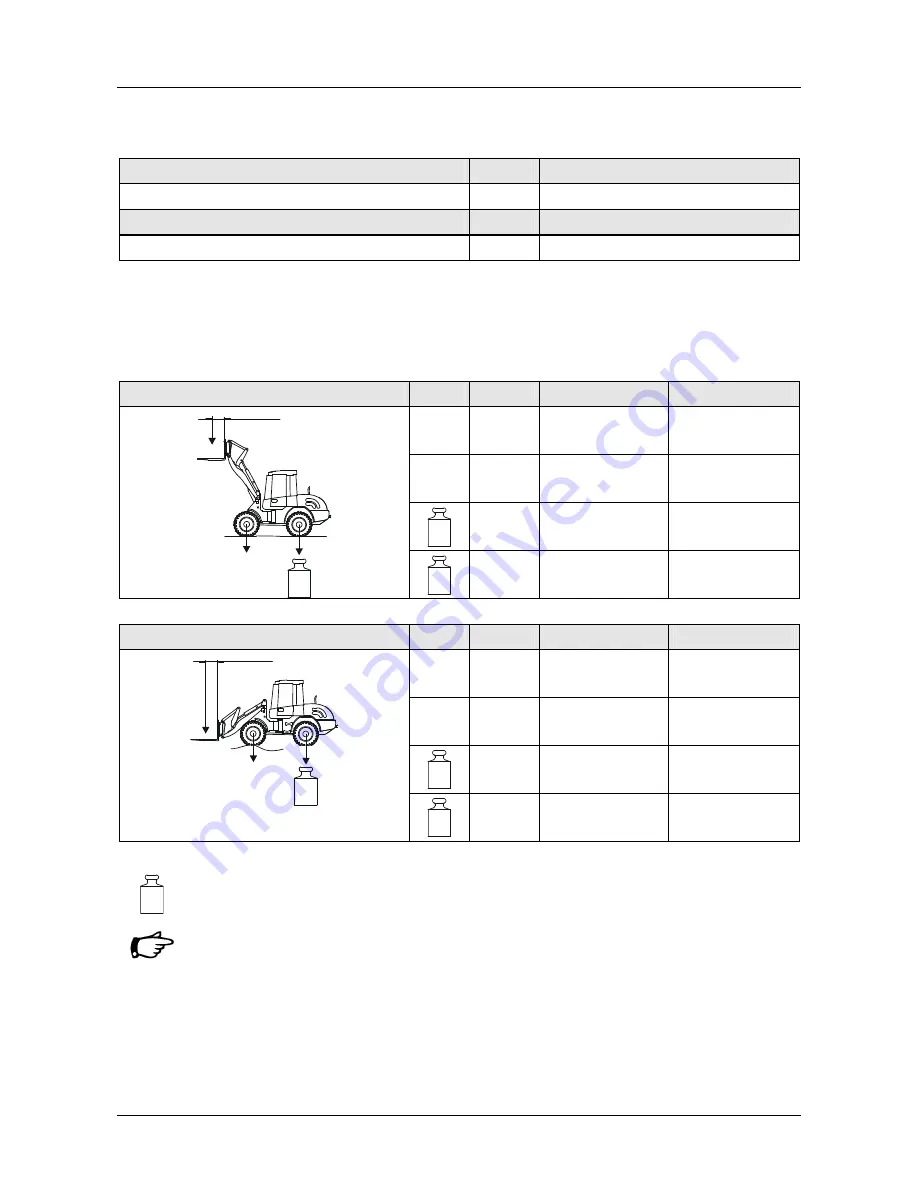

3.15 Fork lift attachment

Fork-arm connection in compliance with ISO/FEM Class 2 Form B, DIN 15 173 / ISO 2328 respectively

Width of fork carrier

mm

1,240

Length of forks

mm

1,100

Fork cross section

mm

100x45

Max. stacking height

mm

3,070

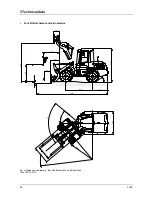

The payloads are determined in compliance with DIN 24094 / ISO 14397-1 and EN ISO 474-3 respectively

with a safety factor of 1.25 or 80% of the tipping load and the machine moving over level ground.

The payloads in crane operation are determined with load hooks on the forks, at a 500 mm load radius from

the rear of the fork, according to ISO 14397-1 with a stability factor of 2.0 / 50% of the tipping load.

The payloads are valid for a machine fitted with 12.5-20MPT 10PR tires and in a condition in compliance with

ISO 6016.

Total lift range

S=2.0

S=1.25

kg

1,250

2,050

lbs

2,750 4,400

kg

lbs

kg

1,380

2,250

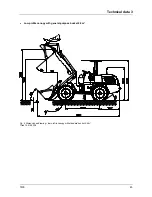

500mm

19,7inch

+0,5bar

+7,3psi

+

kg

lbs

kg

lbs

lbs

3,030 4,840

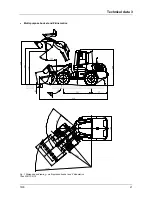

Transport position

S=1.67

S=1.25

kg

1,720

2,300

lbs

3,790

5,060

kg

lbs

kg 1,870

2,500

500mm

19,7inch

+0,5bar

+7,3psi

+

kg

lbs

kg

lbs

lbs 4,120

5,500

kg

lbs

If screw-on rear axle weights or rear tires with hydroinflation are used.

During fork lift operations, the tire pressure of the front wheels must be increased by at least

0.5 bar.

Summary of Contents for TW9

Page 6: ...Table of Contents TW9...

Page 12: ...6 TW9...

Page 42: ...3 Technical data 36 TW9...

Page 46: ...4 Operation 40 TW9 Instrument panel Fig 10 2 Operator controls...

Page 58: ...4 Operation 52 TW9...

Page 112: ...9 Appendix 106 TW9...