2 Safety and Accident Prevention

14

TW9

2.16 Change of work attachments,

maintenance, repair

Earth-moving machines shall only be converted,

maintained or serviced under the guidance of a

suitable person designated by the plant operator

and following the manufacturer’s Operating

Instructions.

After every change of work attachments, the driver

must convince himself that the quick-attach system

is correctly fastened and locked.

Work on e.g.

•

brake

systems,

•

steering

systems,

•

hydraulic

and

•

electric

systems

of the machine is only to be carried out by expert

personnel specially trained in these areas.

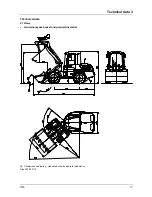

Stability must be ensured during all type of work on

the machine at all times.

The work equipment must be secured against

movement by lowering it to the ground or

equivalent measures, e.g. cylinder supports,

trestles. With the engine running, the unprotected

articulation range of articulated loaders shall not be

entered.

When jacking up earth-moving machines, jacking

devices must be positioned so that they cannot

slip. Jacks must be positioned and applied

absolutely straight, without tilting.

Raised earth-moving machines must be supported

by suitable structures such as crosswise stacks of

planks, square timbers or steel trusses.

Stabilize the earth-moving machine that has been

lifted with the work attachment, immediately after

lifting with a supporting structure. Work under

raised machines which are only supported by their

hydraulics is forbidden.

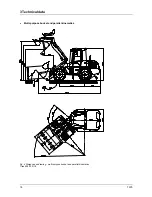

The engine/motor(s) must be turned off prior to all

maintenance and repair work. These requirements

may only be ignored in the case of maintenance or

repair work which cannot be performed without the

engine/motor(s) running.

When performing maintenance and repair work on

the hydraulic system, the hydraulic system must be

relieved of pressure. With the engine turned off,

lower the work equipment to the ground and

actuate all hydraulic control levers until there is no

pressure in the hydraulic system.

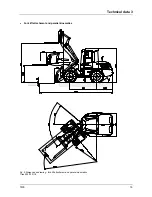

Before working on the electrics or when performing

arc-welding on the machine, the connection to the

battery must be disconnected.

When disconnecting the battery, first the negative

pole then the positive pole must be disconnected.

The battery must be re-connected in reverse order.

During repair work around the battery, it must be

covered with insulating material. Tools should

never be placed on or near the battery.

Protective devices of moving machine parts are

only to be opened or removed after the drive has

been switched off and cannot be switched on

again by unauthorized persons. Protective devices

are e.g. engine/motor covers, doors, protective

grating, trim.

Upon completion of assembly, maintenance or

repair work, all protective devices must once more

be attached in the proper manner.

Load-bearing parts of earth-moving machines are

only to be welded following consultation with the

manufacturer and in accordance with recognized

welding principles.

Protective structures (ROPS; FOPS) are not to be

welded or drilled in any way.

Summary of Contents for TW9

Page 6: ...Table of Contents TW9...

Page 12: ...6 TW9...

Page 42: ...3 Technical data 36 TW9...

Page 46: ...4 Operation 40 TW9 Instrument panel Fig 10 2 Operator controls...

Page 58: ...4 Operation 52 TW9...

Page 112: ...9 Appendix 106 TW9...